Abstract

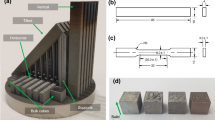

High Cr content Ni-Cr-Ti arc-sprayed coatings have been extensively applied to mitigate corrosion in black liquor recovery boilers in the pulp and paper industry. In a previous article, the effects of key spray parameters on the coating’s microstructure and its composition were investigated. Three coating microstructures were selected from that previous study to produce a dense, oxidized coating (coating A), a porous, low oxide content coating (coating B), and an optimized coating (coating C) for corrosion testing. Isothermal oxidation trials were performed in air at 550 and 900 °C for 30 days. Additional trials were performed under industrial smelt deposits at 400 and 800 °C for 30 days. The effect of the variation in coating microstructure on the oxidation and smelt’s corrosion response was investigated through the characterization of the surface corrosion products, and the internal coating microstructural developments with time at high temperature. The effect of long-term, high-temperature exposure on the interaction between the coating and substrate was characterized, and the mechanism of interdiffusion was discussed.

Similar content being viewed by others

References

R. Luding, R. Thorpe, and R.V. Hinckley, The Development of Twin Wire Arc and HP/HVOF Sprayed Coatings for Coal-Fired Steam Generation Boiler, Adv. Mater. Processes, 2010, 168(2), p 34-36

W. Zanchuk, The Use of Tafaloy 45CT, an Ni-Cr-Ti Alloy as an Arc Sprayed Corrosion Barrier in High Temperature Sulfurous Environments, Surf. Coat. Technol., 1989, 39(40), p 65-69

S. Matthews and M. Schweizer, Optimization of Arc-Sprayed Ni-Cr-Ti Coatings for High Temperature Corrosion Applications, J. Therm. Spray Technol., this issue, 2013

S.T. Bluni and A.R. Marder, Effects of Thermal Spray Coating Composition and Microstructure on Coating Response and Substrate Protection at High Temperatures, Corrosion, 1996, 52(3), p 213-218

K.R. Luer, J.N. DuPont, and A.R. Marder, High Temperature Sulfidation of Fe3Al Thermal Spray Coatings at 600 °C, Corrosion, 2000, 56(2), p 189-198

M.A. Uusitalo, P.M.J. Vuoristo, and T.A. Mantyla, High Temperature Corrosion of Coatings and Boiler Steels in Oxidising Chlorine-Containing Atmosphere, Mater. Sci. Eng. A, 2003, 346, p 168-177

N. Birks, G. Meier, and F. Pettit, High Temperature Oxidation of Metals, Cambridge University Press, Cambridge, 2006

N. Otsuka, Fireside Corrosion, Shreir’s Corrosion (Part IV: High Temperature Corrosion Environments), T. Richardson, Ed., Elsevier, Amsterdam, 2010, p 457-481

D. Young, High Temperature Oxidation and Corrosion of Metals, Elsevier Corrosion Series, T. Burstein, Ed., Elsevier, Amsterdam, 2008

S. Al-Hassan, P.M. Singh, and G.J. Fonder, Effect of Smelt/Gas Interaction on SA-210 Carbon Steel Corrosion, Proceedings of the 1998 International Chemical Recovery Conference, Institute of Paper Science and Technology, Atlanta, 1-4 June 1998, p 901-908

R.A. Peascoe, J.R. Keiser, J.G. Hemrick, M.P. Brady, P. Sachenko, C.R. Hubbard, R.D. Ott, C.A. Blue, and J.P. Gorog, Materials Issues in High Temperature Black Liquor Gasification, TAPPI Fall Technical Conference, Chicago, 2003, p 5037-5045

W.S. Rasband, ImageJ, US National Institute of Health, http://imagej.nih.gov/ij/, 1997-2012

N. Lebrun, Cr-Ni-Ti (Chromium-Nickel-Titanium), Light Metal Ternary Systems: Phase Diagrams, Crystallographic and Thermodynamic Data, G. Effenberg and S. Ilyenko, Ed., Springer, Berlin, 2008

G. Romeo and D.W. McKee, The Na2SO4-Induced Corrosion Properties of Ni-Base Superalloy Phases, J. Electrochem. Soc., 1975, 122(2), p 188-199

M.F. Stroosnijder and W.J. Quadakkers, A Corrosion Study of Ni and Ni-Cr Alloys in SO2/H2O/H2 Atmospheres Using Gas Analysis, Corros. Sci., 1989, 29(9), p 1059-1072

X.G. Zheng and D.J. Young, Sulphide Formation After Pre-oxidation of Chromia Formers, Corros. Sci., 1996, 38(11), p 1877-1897

D. Rezakhani, Corrosion Behaviours of Several Thermal Spray Coatings Used on Boiler Tubes at Elevated Temperatures, Anti-Corros. Methods Mater., 2007, 54(4), p 237-243

B. Singh and S. Prakash, Analytical Studies on the Behavior of Nickel and Cobalt-Base Shrouded Plasma Spray Coatings at Elevated Temperature in Air, Oxid. Met., 2007, 67, p 279-298

T. Sundararajan, S. Kuroda, T. Itagaki, and F. Abe, Steam Oxidation Resistance of Ni-Cr Thermal Spray Coatings on 9Cr-1Mo Steel: Part 1: 80Ni-20Cr, ISIJ Int., 2003, 43(1), p 95-103

T. Sundararajan, S. Kuroda, T. Itagaki, and F. Abe, Steam Oxidation Resistance of Ni-Cr Thermal Spray Coatings on 9Cr-1Mo Steel: Part 2: 50Ni-50Cr, ISIJ Int., 2003, 43(1), p 104-111

K.M. Day and M.A. Dayananda, Analysis of interdiffusion in selected high temperature alloy systems, Heat Treating: Proceedings of the 23rd Heat Treating Society Conference, D. Herring and R. Hill, Eds., ASM International, Materials Park, 2006, p 332-337

“Cr (Chromium) Ternary Alloy Phase Diagrams,” ASM Handbook, Volume 03—Alloy Phase Diagrams, H. Baker and H. Okamoto, Eds., ASM International, Materials Park, 1992, p 3.42-43.49

Acknowledgments

The authors gratefully acknowledge the support of Holster Engineering Company by supplying the wire and spraying the samples for this study. We would also like to thank Warren Blakemore for providing the smelt samples for this study and for his insight on the operation of industrial black liquor recovery boilers. The support provided by Professor Margaret Hyland in facilitating this study is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matthews, S., Schweizer, M. High-Temperature Oxidation and Smelt Deposit Corrosion of Ni-Cr-Ti Arc-Sprayed Coatings. J Therm Spray Tech 22, 932–946 (2013). https://doi.org/10.1007/s11666-013-9939-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9939-2