Abstract

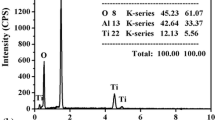

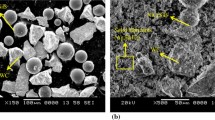

B4C coating was fabricated by vacuum plasma spraying and the tribological properties of the coating against WC-Co alloy were evaluated by sliding wear tests. Al2O3 coating, one of the most commonly used wear-resistant coatings, was employed as comparison in the tribological evaluation. The results obtained show that, the B4C coating is composed of a large amount of nanostructured particles along with some amorphous phases. Both of the friction coefficient and wear rate of the B4C coating are much lower than those of the Al2O3 coating, and the tribological evaluation reveals a decreasing trend for the B4C coating in friction coefficient as well as wear rate with increasing normal load, which is explained in terms of the formation of a protective transfer layer on its worn surface. Tribofilm wear is found to be the dominant wear mechanism involved in the B4C/WC-Co alloy friction pair.

Similar content being viewed by others

References

K.A. Schwetz, L.S. Sigl, J. Greim, and H. Knoch, Wear of Boron Carbide Ceramics by Abrasive Waterjets, Wear, 1995, 181-183, p 268-362

L. Prchlik, S. Sampath, J. Gutleber, G. Bancke, and A.W. Ruff, Friction and Wear Properties of WC-Co and Mo-Mo2C Based Functionally Graded Materials, Wear, 2001, 249, p 1103-1115

H.R. Salimijazi, T.W. Coyle, J. Mostaghimi, and L. Leblanc, Microstructure of Vacuum Plasma-Sprayed Boron Carbide, J. Therm. Spray Technol., 2005, 14(3), p 268-362

H. Lee and R.F. Speyer, Pressureless Sintering of Boron Carbide, J. Am. Ceram. Soc., 2003, 86(9), p 1473-1478

H.L. Zhao, K. Hiragushi, and Y. Mizota, Densification and Mechanical Properties of Mullite/TiO2-Coated B4C Composites, J. Eur. Ceram. Soc., 2003, 23, p 1485-1490

S. Yamada, K. Hirao, Y. Yamauchi, and S. Kanzaki, High Strength B4C-TiB2 Composites Fabricated by Reaction Hot-Pressing, J. Eur. Ceram. Soc., 2003, 23, p 1123-1130

J.L. Sun, C.X. Liu, and C.Y. Duan, Effect of Al and TiO2 on Sinterability and Mechanical Properties of Boron Carbide, Mater. Sci. Eng., A, 2009, 509, p 89-93

J. Kitamura, S. Usuba, Y. Kakudate, H. Yokoi, K. Yamamoto, A. Tanaka, and S. Fujiwara, Structure and Mechanical Properties of Boron Carbide Coatings Formed by Electromagnetically Accelerated Plasma Spraying, Diamond Relat. Mater., 2003, 12, p 1891-1896

O. Sarikaya, Effect of Some Parameters on Microstructure and Hardness of Alumina Coatings Prepared by the Air Plasma Spraying Process, Surf. Coat. Technol., 2005, 190, p 388-393

S.Y. Tao, Z.J. Yin, X.M. Zhou, and C.X. Ding, Sliding Wear Characteristics of Plasma-Sprayed Al2O3 and Cr2O3 Coatings Against Copper Alloy Under Severe Conditions, Tribol. Int., 2010, 43, p 69-75

A. Rabiei and A.G. Evans, Failure Mechanisms Associated with the Thermally Grown Oxide in Plasma-Sprayed Thermal Barrier Coatings, Acta Mater., 2000, 48, p 3963-3976

Z. Ahmad and M. Ahsan, Corrosion Studies on the Plasma-Sprayed Nanostructured Titanium Dioxide Coatings, Anti-Corros. Methods Mater., 2009, 56(4), p 187-195

Y. Zeng, S.W. Lee, and C.X. Ding, Study of Plasma-Sprayed Boron Carbide Coating, J. Therm. Spray Technol., 2002, 11(1), p 129-133

Y. Zeng, C.X. Ding, and S.W. Lee, Young’s Modulus and Residual Stress of Plasma-Sprayed Boron Carbide Coatings, J. Eur. Ceram. Soc., 2001, 21, p 87-91

H. Greuner, M. Balden, B. Boeswirth, H. Bolt, R. Gadow, P. Grigull, G. Hofmann, T. Huber, W. Kasparek, H. Kumric, S. Lindig, G. Matern, M. Mayer, R. Neu, H. Renner, J. Roth, M. Riegert-Escribano, J. Simon-Weidner, and R. Wacker, Evaluation of Vacuum Plasma-Sprayed Boron Carbide Protection for the Stainless Steel First Wall of WENDELSTEIN 7-X, J. Nucl. Mater., 2004, 329-333, p 849-854

H. Bolt, M. Araki, J. Linke, W. Malléner, K. Nakamura, R.W. Steinbrech, and S. Suzuki, Heat Flux Experiments on First Wall Mock-Ups Coated by Plasma Sprayed B4C, J. Nucl. Mater., 1996, 233-237, p 809-813

K. Umeda, Y. Enomoto, A. Mitsui, and K. Mannami, Friction and Wear of Boride Ceramics in Air and Water, Wear, 1993, 169, p 63-68

K. Nishiyama, Sintering and Tribology of Boride Hard Materials, Powder Powder Metall., 1996, 43, p 464-471 (In Japanese)

S. Safai and H. Herman, Microstructural Investigation of Plasma-Sprayed Aluminum Coatings, Thin Solid Films, 1977, 45(2), p 295-307

D.A. Stewart, P.H. Shipway, and D.G. McCartney, Microstructural Evolution in Thermally Sprayed WC-Co Coatings: Comparison Between Nanocomposite and Conventional Starting Powders, Acta Mater., 2000, 48, p 1593-1604

R.G. Bayer, Mechanical Wear Fundamentals and Testing, Chap. 3, 2nd ed., Marcel Dekker, 2004, p 40

R.G. Bayer, Mechanical Wear Fundamentals and Testing, Chap. 3, 2004, p 20

R.G. Bayer, Mechanical Wear Fundamentals and Testing, Chap. 4, 2004, p 85-87

R. Tyagi, D.S. Xiong, and J.L. Li, Effect of Load and Sliding Speed on Friction and Wear Behavior of Silver/h-BN Containing Ni-Base P/M Composites, Wear, 2011, 270, p 423-430

Acknowledgments

This work was jointly supported by the National Natural Science Foundation (for Young Scholar) of China under grant 51102267, Shanghai Science and Technology R&D Fund under grant 11ZR1442100, Open Fund of Key Laboratory of Inorganic Coating Materials, Shanghai Institute of Ceramics, Chinese Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, H., Niu, Y., Lin, C. et al. Fabrication and Tribological Evaluation of Vacuum Plasma-Sprayed B4C Coating. J Therm Spray Tech 21, 1216–1223 (2012). https://doi.org/10.1007/s11666-012-9815-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-012-9815-5