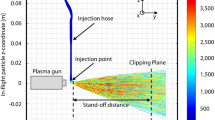

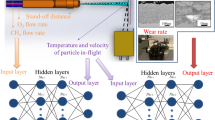

The plasma-sprayed coating architecture and in-service properties are derived from an amalgamation of intrinsic and extrinsic spray parameters. These parameters are interrelated; following mostly non-linear relationships. For example, adjusting power parameters (to modify particle temperature and velocity upon impact) also implies an adjustment of the feedstock injection parameters in order to optimize geometric and kinematic parameters. Optimization of the operating parameters is a first step. Controlling these is a second step and consists of defining unique combinations of parameter sets and maintaining them as constant during the entire spray process. These unique combinations must be defined with regard to the in-service coating properties. Several groups of operating parameters control the plasma spray process; namely (i) extrinsic parameters that can be adjusted directly (e.g., the arc current intensity) and (ii) intrinsic parameters, such as the particle velocity or its temperature upon impact, that are indirectly adjusted. Artificial intelligence (AI) is a suitable approach to predict operating parameters to attain required coating characteristics. Artificial Neural Networks (ANN) and Fuzzy Logic (FL) were implemented to predict in-flight particles characteristics as a function of power process parameters. The so-predicted operating parameters resulting from both methods were compared. The spray parameters are also predicted as a function of achieving a specified hardness or a required porosity level. The predicted operating parameters were compared with the predicted in-flight particle characteristics. The specific case of the deposition of alumina-titania (Al2O3-TiO2, 13% by weight) by APS is considered.

Similar content being viewed by others

Abbreviations

- AI:

-

Artificial Intelligence: study and design of systems capable of perceiving their environment and taking actions maximizing their chance of success

- ANN:

-

Artificial Neural Network: interconnected group of artificial neurons which processes information using a connectionist approach to computation

- Artificial neuron:

-

(related to Artificial Neural Network) basic unit in an artificial neural network based on an abstraction of a biological neuron and which receives one or more inputs (representing the one or more dendrites) and sums them to produce an output (synapse). The sums of each node are weighted and the sum is passed through a non-linear function known as transfer function

- Back-propagation:

-

(related to Artificial Neural Network) most used technique used for training feed-forward artificial neural networks (networks that have no feedback or no connections that loop)

- Defuzzification:

-

(related to Fuzzy Logic) procedure during which a real value from the result of the inference is produced and can be used as a fuzzy control input

- FL:

-

Fuzzy Logic: derived from fuzzy set theory dealing with reasoning that is approximate rather than precisely deduced from classical predicate logic

- Fuzzification:

-

(related to Fuzzy Logic) procedure during which the real input variables (power parameters in the present study) are translated in terms of fuzzy sets

- MF:

-

Membership Function (related to Fuzzy Logic): associates a weighting with each of the inputs that are processed, defines functional overlap between inputs, and ultimately determines an output response. In the present study, MF correspond to the power parameters

References

R.W. Smith, R. Knight, Thermal Spraying I: Powder Consolidation—From Coating to Forming, J. Mater., 1995, 47 (8), p 32-39

M. Prystay, P. Gougeon, C. Moreau, Structure of Plasma Sprayed Zircona Coatings Tailored by Controlling the Temperature and Velocity of the Sprayed Particles, J. Therm. Spray Technol., 2001, 10 (1), p 67-75

M.M. Nelson, W.T. Illingworth, A Practical Guide to Neural Nets, 3rd Printing. Addison-Wesley, New York, 1991

H.K.D.H. Bhadeshia, Neural Networks in Materials Science, ISIJ Int., 1999, 39, p 966-979

S. Guessasma, G. Montavon, and C. Coddet, On the Neural Network Concept to Describe the Thermal Spray Deposition Process: Correlation Between In-flight Particles Characteristics and Processing Parameters, Proceedings of the International Thermal Spray Conference 2002, E.F. Lugcheider, Ed., (Düsseldorf), DVS-Verlag, 2002, p 435-440

M.-D. Jean, C.-D. Liub, J.-T. Wang, Design and Development of Artificial Neural Networks for Depositing Powders in Coating Treatment, Appl. Surf. Sci., 2005, 245, p 290-303

M.-D. Jean, B.-T. Lin, J.-H. Chou, Design of a Fuzzy Logic Approach Based on Genetic Algorithms for Robust Plasma-Sprayed Zirconia Depositions, Acta Mater., 2007, 55, p 1985-1997

M.-D. Jean, B.-T. Lin, J.-H. Chou, Design of a Fuzzy Logic Approach for Optimization of Reinforced Zirconia Depositions Using Plasma Sprayings, Surf. Coat. Technol., 2006, 201, p 3129-3138

J. Vuttulainen, E. Hämäläinen, R. Hernberg, P. Vuoristo, T. Müntyla, Novel Method for In-flight Particle Temperature and Velocity Measurements in Plasma Spraying Using a Single CCD Camera, J. Therm. Spray Technol., 2001, 10(1), p 94-104

S. Guessasma, G. Montavon, C. Coddet, On the Implementation of the Fractal Concept to Quantify Thermal Spray Deposit Surface Characteristics, Surf. Coat. Technol., 2003, 173(1), p 24-38

S.O.T. Ogaji, L. Marinai, S. Sampath, R. Singh, S.D. Prober, Gas-Turbine Fault Diagnostics: A Fuzzy-Logic Approach, Appl. Energy., 2005, 82(1), p 81-89

G. E. D’Errico, Fuzzy Control Systems with Application to Machining Processes, J. Mater. Process. Technol., 2001, 109, p 38-43

E.H. Mamdani, S. Assilian, An Experiment in Linguistic Synthesis with a Fuzzy Logic Controller, Int. J. Man Mach. Stud., 1975, 7(1), p 1-13

I. Eker, Y. Torun, Fuzzy Logic Control to be Conventional Method, Energy Convers. Manag., 2006, 47(4), p 377-394

T. Fraichard, P. Garnier, Fuzzy Control to Drive Car Like Vehicles, Robot. Auton. Syst., 2001, 34(1), p 1-22

D.T. Pham, L. Xing, Neural Networks for Identification, Prediction and Control, 2nd Printing. Springer, London, Great Britain, 1995

N.O. Attoh-Okine, Analysis of Learning Rate and Momentum Term in Back Propagation Neural Network Algorithm Trained to Predict Pavement Performance, Adv. Eng. Softw., 1999, 30(4), p 291-302

C.M. Bishop, Training with Noise Is Equivalent to Tikhonov Regularization, Neural Comput., 1995, 7(1), p 108-116

L.M. Romeo, R. Gareta, Neural Network for Evaluating Boiler Behaviour, Appl. Therm. Eng., 2006, 26, p 1530-1536

H.B. Celikoglu, Application of Radial Basis Functions and Generalized Regression Neural Networks in Non-Linear Utility Function Specification for Travel Mode Choice Modeling, Math. Comput. Model., 2006, 44, p 640-658

Y. Reich, S.V. Barai, Evaluating Machine Learning Models for Engineering Problems, Artif. Intell. Eng., 1999, 13(3), p 257-272

R. Kingswell, K.T. Scott, L.L. Wassell, Optimizing the Vacuum Plasma Spray Deposition of Metal, Ceramic and Cermet Coatings Using Designed Experiments, J. Therm. Spray Technol., 1993, 2(2), p 179-186

E. Pfender, Fundamental Studies Associated with the Plasma Spray Process, Surf. Coat. Technol., 1988, 34(1), p 1-14

E. Lugscheider, A. Fischer, D. Koch, N. Papenfub, Diagnostic of In-flight Particle Properties and Resulting Coating Qualities on Atmospheric Plasma Spray Process, Thermal Spray 2001: New Surfaces for a New Millennium, C.C. Berndt, K.A. Khor, E.F. Lugscheider, Eds., (Materials Park, OH), ASM International, 2001, p 751-758

M. Tului, F. Ruffni, F. Arezzo, S. Lasisz, Z. Znamirowski, L. Pawlowski, Some Properties of Atmospheric Air and Inert Gas High-Pressure Plasma Sprayed ZrB2 Coatings, Surf. Coat. Technol., 2002, 151-152, p 483-489

M. Vardelle A. Vardelle P. Fauchais, Diagnostics for Particulate Vaporization and Interactions with Surfaces, Pure Appl. Chem., 1992, 64(5), p 637-644

J. Patru, Modélisation du développement des contraintes résiduelles au sein de dépôts plasma de zircone et d’acier (modeling of the development of reidual stresses within zircone and steel plasma-sprayed coatings), Ph.D. Thesis, n. 64, University of Limoges, France, 2005, in French

D.J. Varacalle, H. Herman, G.A. Bancke, W.L. Riggs, Vacuum Plasma-Sprayed Alumina-Titania Coatings, Surf. Coat. Technol., 1992, 54-55, p 19-24

D.R. Marsh, N.E. Weare, D.L. Walker, Process Variables in Plasma-Jet Spraying, J. Met., 1961, 2, p 473-478

M. Friis, C. Persson, J. Wigren, Influence of Particle In-flight Characteristics on the Microstructure of Atmospheric Plasma Sprayed Yttria Stabilized ZrO2, Surf. Coat. Technol., 2001, 141, p 115-127

I.A. Fisher, Variables Influencing the Characteristics of Plasma-Sprayed Coatings. Int. Metall. Rev., 1972, 17, p 117-136

T.J. Steeper, D.J. Varacalle, G.C. Wilson, W.L. Riggs, A.J. Rotolico, J.E. Nerz, A Design of Experiment Study of Plasma Sprayed Alumina-Titania Coatings, Thermal Spray: Advances in Coatings Technology, C.C. Berndt, Ed., (Materials Park, OH) ASM International, 1992, p 415-420

T.J. Steeper, A.J. Rotolico, J.E. Nerz, W.L. Riggs, D.J. Varacalle, G.C. Wilson, A Tagushi Experimental Design Study of Plasma Sprayed Alumina-Titania Coatings, Thermal Spray Coatings: Properties, Processes and Applications, T.F. Bernecki, Ed., (Materials Park, OH) ASM International, 1992, p 13-20

A.F. Kanta, G. Montavon, M.P. Planche, C. Coddet, Plasma Spray Process on-Line Control by Artificial Intelligence Methodology, Adv. Eng. Mater., 2007, 9, p 105-113

Acknowledgment

The French National Agency for Innovation (OSEO-ANVAR, grant number J 06.09.002 l) and the CNRS MRCT “Plasma” network are gratefully acknowledge for their financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kanta, AF., Montavon, G., Vardelle, M. et al. Artificial Neural Networks vs. Fuzzy Logic: Simple Tools to Predict and Control Complex Processes—Application to Plasma Spray Processes. J Therm Spray Tech 17, 365–376 (2008). https://doi.org/10.1007/s11666-008-9183-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-008-9183-3