Abstract

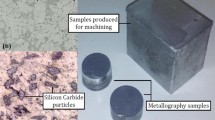

An attempt was made to evaluate machining of eutectic Al-Si (LM6) and hypoeutectic Al-Si (LM25) alloys reinforced with 10, 15, and 20% SiCp of two particle sizes using conventional high-speed steel (HSS) and tungsten carbide (WC) tools by varying cutting speed, feed, depth of cut, and environment. Machining of metal matrix composites (MMCs) is a difficult task using HSS and WC tools. The tool life of both these conventional tools was observed to decrease with increasing percentage and coarseness of SiCp in the composites. Tungsten carbide tools had a longer tool life than HSS under all the different conditions studied. Contrary to the known phenomenon of enhanced tool life in machining monolithic alloys with the use of cutting fluid, the tool life of WC/HSS tool in machining composites with cutting fluid was only 10 to 20% of that without cutting fluid.

Similar content being viewed by others

References

K.G. Satyanarayana, R.M. Pillai, and B.C. Pai, Aluminium Cast Metal Matrix Composites, Handbook of Ceramics and Composites, Vol 1, Synthesis and Properties, N.P. Cheremisinoff, Ed., Marcel Dekker Inc., 1990, p 555–599

P.K. Rohatgi, Future Directions in Solidification of Metal Matrix Composites, Key Engineering Materials, G.M. Newaz et al., Ed., Trans. Tech., Switzerland, Vol 104–107, 1995, p 293–312

D.J. Lloyd, Particle Reinforced Aluminium and Magnesium Matrix Composites, Int. Mater. Rev., Vol 39, 1994, p 1–23

J.E. Allison and G.S. Cole, Metal Matrix Composites in the Automotive Industries, J. Met., Vol 45 (No. 4), 1993, p 10–15

L.M. Orsborn and G.R. Shook, Machining Experience with Discontinuously Reinforced, Proc. Sym. on Machining of Composite Materials (Chicago, IL), 1–5 Nov 1992, p 57–61

B.H. Yan and C.C. Wang, Machinability of SiC Particle Reinforced Aluminium Alloy Composite Material, J. Jpn. Inst. Light Met., Vol 43 (No. 4), 1993, p 187–192

A. Jawaid, S. Barnes, and S.R. Ghadimzadeh, Drilling of Particulate Aluminium Silicon Carbide Metal Matrix Composites, Proc. Sym. on Machining of Composite Materials (Chicago, IL), 1–5 Nov 1992, p 35–47

C. Lane, Machinability of Aluminium Composites as a Function of Matrix Alloy and Heat Treatment, Proc. Sym. on Machining of Composite Materials (Chicago, IL), 1–5 Nov 1992, p 3–15

C. Lane, The Effect of Different Reinforcements on PCD Tool Life of Aluminium Composites, Proc. Sym. on Machining of Composite Materials (Chicago, IL), 1–5 Nov 1992, p 17–27

P. Chen, High Performance Machining of SiC Whisker Reinforced Aluminium Composite by Self Propelled Rotary Tools, CIRP Ann., Vol 41, 1992, p 59–62

Metals Hand Book, Vol 16, Machining, 9th ed., ASM International, p 19–48, 75, 107, 761–770

C.T. Lane, Requirements for Machining MMC Castings, Trans. AFS, Vol 101, 1993, p 525–529

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Narahari, P., Pai, B.C. & Pillai, R.M. Some aspects of machining cast Al-SiCp composites with conventional high speed steel and tungsten carbide tools. J. of Materi Eng and Perform 8, 538–542 (1999). https://doi.org/10.1007/s11665-999-0006-6

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s11665-999-0006-6