Abstract

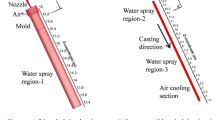

The influences of different electromagnetic field intensities on the solidification structures of industrially centrifugally cast 25Cr20Ni stainless steel tubes have been investigated in detail. The results reveal that the electromagnetic field exerted during the centrifugal solidification causes a marked variation in the structures of the cast tubes. With an increase of the electromagnetic field intensity, the area fraction of the equiaxed structures in transverse sections of the cast tubes increases, and the macrostructures are gradually refined. The distribution of the eutectic carbides changes from the dendrite boundaries to the grain boundaries. However, an excessive electromagnetic field intensity gives rise to many intergranular cast defects formed along the inner walls of the centrifugally cast tubes. The effects of fluid flow induced by the electromagnetic field on the solidification process of the centrifugally cast tubes are the primary reason for the previously mentioned structure variations.

Similar content being viewed by others

References

L.T. Shinoda, M.B. Zaghloul, Y. Kondo, and R. Tanaka, The Effect of Single and Combined Additions of Ti and Nb on the Structure and Strength of the Centrifugally Cast HK40 Steel, Trans. ISIJ, Vol 18, 1978, p 139–148

H. Wen-Tai and R.W.K. Honeycombe, Structure of Centrifugally Cast Austenitic Stainless Steels: Part 1 HK40 As Cast and after Creep between 750 and 1000°C: Part 2. Effects of Nb, Ti, and Zr, Mater. Sci. Technol., Vol 1 (No. 5), 1985, p 385–397

G.D. Barbabela, L.H. Almeida, T.L. Silveira, and I. May, Phase Characterization in Two Centrifugally Cast HK Stainless Steel Tubes, Mater. Char., Vol 26 (No. 1), 1991, p 1–7

G.D.A. Soares, L.H. Almeida, T.L. Silveira, and I. May, Niobium Additions in HP Heat-Resistant Cast Stainless Steels, Mater. Char., Vol 29 (No. 4), 1992, p 387–396

C.W. Thomas, M. Borshevsky, and A.N. Marshall, Assessment of Thermal History of Niobium Modified HP50 Reformer Tubes by Microstructural Methods, Mater. Sci. Technol., Vol 8 (No. 10), 1992, p 855–861

R.A.P. Ibanez, G.D.A. Soares, L.H. Almeida, and I. May, Effects of Si Content on the Microstructure of Modified-HP Austenitic Steels, Mater. Char., Vol 30 (No. 4), 1993, p 243–249

C.W. Thomas, K.J. Stevens, and M.J. Ryan, Microstructure and Properties of Alloy HP50-Nb: Comparison of As Cast and Service Exposed Materials, Mater. Sci. Technol., Vol 12 (No. 5), 1996, p 469–475

J. Liu, Z. Wang, Z. Pan, and B. Sun, Effects of Carbon, Nickel, and Molybdenum on the High Temperature Strength of Fe-Cr-Ni Alloys, Mater. Trans. JIM, Vol 37 (No. 2), 1996, p 138–141

E.A.A.G. Ribeiro, R. Papaleo, and J.R.C. Guimaraes, Microstructure and Creep Behavior of a Niobium Alloyed Cast Heat-Resistant 26% Cr Steel, Metall. Mater. Trans., Vol 17A, 1986, p 691–696

L.H. Wolfe, Laboratory Investigation of High Temperature Alloy Corrosion and Failures, Mater. Perform., (No. 4), 1978, p 38–44

R.H. Kane, Effects of Silicon Content and Oxidation Potential on the Carburization of Centrifugally Cast HK-40, Corrosion, Vol 37 (No. 4), 1981, p 187–199

T. Shinohara, I. Kohchi, K. Shibata, J. Sugitani, and K. Tsuchida, Development of Nondestructive Technique for Measuring Carburization Thickness and of a New Carburization-Resistant Alloy, Werkst. Korros., Vol 37, 1986, p 410–418

W. Zhang, Y. Yang, Q. Liu, Y. Zhu, Q. Zhang, and Z. Hu, Effects of Electromagnetic Stirring and Water Cooling on Structure and Segregation in Centrifugally Cast Al-Si Eutectic Alloy, Mater. Sci. Technol., Vol 14 (No. 4), 1998, p 306–311

Y. Yang, Q. Liu, Y. Jiao, Z. Hu, G. Jia, G. Zhang, Y. Gao, and J. Zhang, Solidification Structure of 25Cr-20Ni-Fe-C Alloy by Electromagnetic Centrifugally Casting, Proceedings of International Symposium on Electromagnetic Processing of Materials (Nagoya, Japan), ISIJ Int., Oct 1994, p 420–425

Y. Yang, Q. Liu, Y. Jiao, Z. Hu, J. Zhang, and Y. Gao, Effect of Fluid Flow on Eutectic Carbide of Steel HK40, Proceedings of the Second Pacific Rim International Conference on Advanced Materials and Processing (Kyongju, Korea), Korea Institute of Metals and Materials, June 1995, p 149–153

J. Szekely, C.W. Chang, and R.E. Ryan, The Measurement and Prediction of the Melt Velocities in a Turbulent, Electromagnetically Driven Recirculating Low Melting Alloy System, Metall. Trans. B, Vol 8, 1977, p 333–340

H. Fredriksson and A. Olsson, Mechanism of Transition from Columnar to Equiaxed Zone in Ingots, Mater. Sci. Technol., Vol 2 (No. 5), 1986, p 508–516

G.S. Cole and G.F. Bolling, Enforced Fluid Motion and the Control of Grain Structures in Metal Castings, Trans. AIME, Vol 239 (No. 11), 1967, p 1824–1835

W.D. Griffiths and D.G. McCartney, The Effect of Electromagnetic Stirring during Solidification on the Structures of Al-Si Alloys, Mater. Sci. Eng. A, Vol 216, 1996, p 47–60

K. Nishino and N. Kagawa, Structural Diagram of Austenitic 25% Cr-20Ni-Fe-C Type Alloys, Tetsu-to-Hagane, Vol 58 (No. 1), 1972, p 107–118

W. Zhang, Y. Yang, Q. Liu, Y. Zhu, and Z. Hu, Numerical Simulation of Fluid Flow in Electromagnetic Centrifugal Casting, Model. Simul. Mater. Sci. Eng., (No. 4), 1996, p 421–432

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wu, X.Q., Yang, Y.S., Zhang, J.S. et al. Structure characteristics in industrially centrifugally cast 25Cr20Ni stainless steel tubes solidified under different electromagnetic field intensity. J. of Materi Eng and Perform 8, 525–530 (1999). https://doi.org/10.1007/s11665-999-0004-8

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s11665-999-0004-8