Abstract

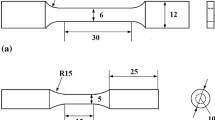

Fatigue represents a common mechanical condition during service for materials used in structural components. This type of loading becomes particularly critical when alternating stress amplitude may be expected to vary, or change, in some way during the service life. Such variations and changes in load amplitude make the direct use of standard S-N curves inapplicable, because these curves are developed and presented for constant stress amplitude operation. In the present paper, results of cumulative damage under fatigue of porous materials are reported. The specimens used were produced by compacting and sintering iron powder. Their as-sintered porosity contents were P 0 = 4.1 and 12.4 %. Uniaxial fatigue tests (tensile-compression) were carried out at room temperature on a hydraulic testing machine.

Similar content being viewed by others

References

K.D. Christian and R.M. German, Relation between Pore Structure and Fatigue Behavior in Sintered Fe-Cu-C, Int. J. Powder Metall., Vol 31 (No. 1), 1995, p 51–61

P. Beiss and M. Dalgic, Effect of Pore Structure on Bending Fatigue Strength of Sintered Steel, Advances in Powder Metallurgy and Particulate Materials, Proc. 1996 World Congress on Powder Metallurgy and Paniculate Materials, Vol 5, Metal Powder Industries Federation, 1996

G. Straffelini, V. Fontanari, A. Molinari, and B. Tesi, Tensile and Fatigue Behaviour of Phosphorus Alloyed Sintered Steels, Powder Metall., Vol 36,1993, p 135–141

R. A. Chernenkoff, S. Mockarski, and D.A. Yeager, Increased Fatigue Strength of Powder Forged Connecting Rods by Optimised Shot Peening, Powder Metall., Vol 38, 1995, p 196–200

A. Bergmark, Influence of MnS on the Fatigue Properties of Distalloy AE + 0.5% C, Advances in Powder Metallurgy and Particulate Materials, Proc. 1996 World Congress on Powder Metallurgy and Paniculate Materials, Vol 5, Metal Powder Industries Federation, 1996

F.J. Esper, G. Leuze, and C.M. Sonsino, Characteristic Properties of Powder Metallurgical Materials Relevant to Fatigue Design, Powder Metall. Int., Vol 13, 1981, p 203–208

E. Klar, D.F. Berry, P.K.. Samal, J.J. Lewandowski, and J.D. Rigney, Fracture Toughness and Fatigue Crack Growth Response of Copper Infiltrated Steels, Int. J. Powder Metall., Vol 31, 1995, p 317–324

C.M. Sonsino, Fatigue Design for Powder Metallurgy, Powder Metall., Vol 33,1990, p 235–245

J. Holmes and R.A. Queeney, Fatigue Crack Initiation in a Porous Steel, Powder Metall., Vol 28,1985, p 231–235

K. Sobczyk and B.F. Spencer, Jr., Random Fatigue: From Data to Theory, Academic Press, Inc., 1992

J.A. Collins, Failure of Materials in Mechanical Design, John Wiley & Sons, 1981

R.R. Gatts, Application of a Cumulative Damage Concept to Fatigue, ASME Transactions, Series D, Vol 83,1961, p 529–536

D.L. Henry, Theory of Damage Accumulation in Steel, ASME Transactions, Vol 77,1955, p 913–921

S.S. Manson, J.C, Frecke, and C.R. Ensign, Applications of a Double Linear Damage Rule to Cumulative Fatigue, Fatigue Crack Propagation, STP-415, ASTM, 1967, p 384–395

N.A. Fleck and R.A. Smith, Effect of Density on Tensile Strength, Fracture Toughness, and Fatigue Crack Propagation Behaviour of Sintered Steel, Powder Metall., Vol 13, 1981, p 121–125

J.L. Bogdanoff, A New Cumulative Damage Model, J. Appl. Mech., 1978, Part I, No. 45, p 245–250; Part II, No. 45, p 251–257; Part III, No. 45, p 733–739

J.L. Bogdanoff andF. Kozin, A New Cumulative Damage Model, Part IV, J. Appl. Mech., No. 47, 1980, p 40–44

K. Sobczyk, Stochastic Models for Fatigue Damage of Materials, Adv. Appl. Probabil., Vol 19, 1987, p 652–673

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Palma, E.S. Influence of porosity on fatigue cumulative damage of sintered iron. J. of Materi Eng and Perform 6, 615–618 (1997). https://doi.org/10.1007/s11665-997-0054-8

Issue Date:

DOI: https://doi.org/10.1007/s11665-997-0054-8