Abstract

Reinforced concrete rod produced by European Community countries must comply with standards that establish minimum strength and tensile properties along with other technological and geometrical characteristics; however, possible variability within the assigned limits is not specified. Consequently, a number of manufacturing methods are now used, with the result that over time the mechanical properties of these products vary widely. Increased competition has led to the development of new procedures incorporating both process and quality control.

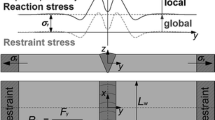

One example is a process based on the heat treatment undergone by the metal bars leaving the final stand of the rolling mill train. In this way, the mechanical and technological properties can be graduated, thereby enhancing strength (particularly yield point) without altering the deformability of the material. This procedure does away with the need to alter the chemical composition of the steel used to manufacture the rods. Process adjustment still relies on the experience of the production manager, however. This paper examines the possibility of applying fuzzy logic computer techniques to the heat treatment process in order to render it more rational and independent of operator unreliability.

Similar content being viewed by others

References

M. Korchynsky and P. Wille, Acciai saldabili di elevata resistenza per tondo per cemento armato con aggiunta di vanadio e azoto, Metall. ItaL, No. 11, 1984, p 481–491

V. Sergi, Applicazione di reti neurali per la previsione delle caratteristiche meccaniche di acciai dolci dopo laminazione, Applicazione dell’intelligenza artificiale all’ingegneria, Liguori, 1993,p177–194

“A New Process for the Production of High Yield Strength Concrete Reinforcing Bars,” Centre de Recherches Métallurgiques, Liège, Belgium, 1972

V.M. Kondratenko et al., Inline Quenching and Tempering of 32 mm dia. Reinforcing Steel, Steel USSR, No. 6,1989, p 262–265

M.A. Grossmann and E.C. Bain, Principles of Heat Treatment, American Society for Metals, 1964

G. Giorleo, V. Sergi, and F. Capece, Impiego degli insiemi fuzzy per il controllo simulate del processo tempcore nella fabbricazione del tondo per c.a., Applications of Artificial Intelligence Techniques in Engineering, Liguori, 1995, p 287–298

H.Y. Wong, Heat Transfer for Engineers, Longman, 1977

J.S.R. Jang, ANFIS: Adaptive Networks based Fuzzy Inference Systems, IEEE Trans. Syst. Man. Cybernet., Vol 23 (No. 3), May 1993, p 665–685

B. Kosko, Neural Networks and Fuzzy Systems, Prentice Hall, 1992

L.A. Zadeh, Fuzzy Sets, Inform. Control, No. 8,1965, p 338–353

L.A. Zadeh, Fuzzy Algorithms, Inform. Control, No. 12, 1968, p 94–102

L.A. Zadeh, Fuzzy Logic, Computer, Vol 21/4, 1988, p 83–93

A. Kaufmann and M.M. Gupta, Introduction to Fuzzy Arithmetic: Theory and Applications, Van Nostrand Reinhold, 1991

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Giorleo, G., Memola Capece Minutolo, F. & Sergi, V. Fuzzy logic modeling and control of steel rod quenching after hot rolling. J. of Materi Eng and Perform 6, 599–604 (1997). https://doi.org/10.1007/s11665-997-0051-y

Issue Date:

DOI: https://doi.org/10.1007/s11665-997-0051-y