Abstract

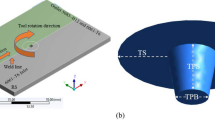

The machined surface residual stress plays a critical role in stress corrosion cracking resistance and fatigue performance of austenitic stainless steels. Controlling the residual stress by changing machining parameters is an effective way to improve the service performance of components. This paper explores the effects of processing parameters and tool geometric parameters on residual stress by establishing an analytical model for residual stress evaluation on machined surface. Considering the thermo-mechanical coupling effects of machining, a multi-physics framework of orthogonal cutting process is built up. From the coupling mechanical and thermal loads, the variations of stress, strain and temperature are modelled by an elastoplastic procedure. Based on the mechanism of residual stress and the loading-unloading model, the prediction of residual stress is achieved. Experimental tests are conducted for model validation. By simulating the cutting processes under different conditions and analyzing the main factors that affecting the stress/strain and temperature fields, the effects of cutting parameters and tool geometric parameters on residual stress are revealed.

Similar content being viewed by others

References

M. James, D. Hughes, Z. Chen, H. Lombard, D. Hattingh, D. Asquith, J. Yates, and P. Webster, Residual Stresses and Fatigue Performance, Eng. Fail. Anal., 2007, 14, p 384–395.

O. Takakuwa and H. Soyama, Effect of Residual Stress on the Corrosion Behavior of Austenitic Stainless Steel, Adv. Chem. Eng. Sci., 2014, 5, p 62.

W. Zhang, Y. Li, H. Dong, C. Yang, X. Jiang, D. Lou, H. Xue, K. Fang, and X. Wang, Correlation Between Machining-Induced Surface Alterations and Stress Corrosion Cracking Susceptibility of au Stenitic Stainless Steels, J. Mater. Res. Technol., 2023, 26, p 5076–5094.

W. Zhang, X. Wang, S. Wang, H. Wu, C. Yang, Y. Hu, K. Fang, and H. Jiang, Combined effects of machining-induced residual stress and external load on SCC initiation and early propagation of 316 stainless steel in high temperature high pressure water, Corros. Sci., 2021, 190, p 109644.

S. Qu, C. Wei, Y. Yang, P. Yao, D. Chu, Y. Gong, D. Zhao, and X. Zhang, Grinding mechanism and surface quality evaluation strategy of single crystal 4H-SiC, Tribol. Int., 2024, 194, p 109515.

Y. Changfeng, W. Daoxia, T. Liang, R. Junxue, S. Kaining, and Y. Zhenchao, Effects of Cutting Parameters on Surface Residual Stress and its Mechanism in High-Speed Milling of TB6, Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf., 2013, 227, p 483–493.

K. Huang and W. Yang, Analytical Analysis of the Mechanism of Effects of Machining Parameter and Tool Parameter on Residual Stress Based on Multivariable Decoupling Method, Int. J. Mech. Sci., 2017, 128, p 659–679.

Z. Ping, W. Penghao, Y. Xiujie, Z. Yanchun, and Y. Xiao, Influence of Tool Geometric Parameters on the Residual Stress of 7A04 Aluminum Alloy in LSEM, Int. J. Adv. Manuf. Technol., 2022, 120, p 1707–1728.

W. Zhang, H. Dong, Y. Li, C. Yang, and H. Xue, Combining Turning with Slide Burnishing to Improve Surface Integrity and Stress Corrosion Resistance, J. Manuf. Process., 2023, 107, p 16–33.

N.S. Rossini, M. Dassisti, K.Y. Benyounis, and A.G. Olabi, Methods of Measuring Residual Stresses in Components, Mater. Des., 2012, 35, p 572–588.

J.C. Outeiro, D. Umbrello, and R. M’Saoubi, Experimental and Numerical Modelling of the Residual Stresses Induced in Orthogonal Cutting of AISI 316L Steel, Int. J. Mach. Tools Manuf, 2006, 46, p 1786–1794.

Z.-C. Lin, Y.-Y. Lin, and C. Liu, Effect of Thermal Load and Mechanical Load on the Residual Stress of a Machined Workpiece, Int. J. Mech. Sci., 1991, 33, p 263–278.

M.N. Nasr, E.-G. Ng, and M. Elbestawi, Modelling the Effects of Tool-Edge radIus on Residual Stresses When Orthogonal Cutting AISI 316L, Int. J. Mach. Tools Manuf, 2007, 47, p 401–411.

F. Valiorgue, J. Rech, H. Hamdi, P. Gilles, and J. Bergheau, A New Approach for the Modelling of Residual Stresses Induced by Turning of 316L, J. Mater. Process. Technol., 2007, 191, p 270–273.

F. Valiorgue, J. Rech, H. Hamdi, P. Gilles, and J.M. Bergheau, 3D Modeling of Residual Stresses Induced in Finish Turning of an AISI304L Stainless Steel, Int. J. Mach. Tools Manuf, 2012, 53, p 77–90.

A.M. Group, J. Merwin, and K. Johnson, An Analysis of Plastic Deformation in Rolling Contact, Proc. Inst. Mech. Eng., 1963, 177, p 676–690.

M. Wan, X.Y. Ye, D.Y. Wen, and W.H. Zhang, Modeling of Machining-Induced Residual Stresses, J. Mater. Sci., 2019, 54, p 1–35.

K.L. Johnson, Contact Mechanics, Cambridge University Press, Cambridge, 1987.

P.L.B. Oxley, A Mechanics of Machining Approach to Assessing Machinability, Proceedings of the Twenty-second International Machine Tool Design and Research Conference. B.J. Davies Ed., Macmillan Education, London, 1982, p 279–287. https://doi.org/10.1007/978-1-349-06281-2_35

D.J. Waldorf, R.E. DeVor, and S.G. Kapoor, A Slip-Line Field for Ploughing During Orthogonal Cutting, J. Manuf. Sci. Eng. Trans. Asme, 1998, 120, p 693–690.

S. Liang and J.-C. Su, Residual Stress Modeling in Orthogonal Machining, CIRP Ann., 2007, 56, p 65–68.

J. Zheng, Y. Shang, Y. Guo, H. Deng, and L. Jia, Analytical Model of Residual Stress in Ultrasonic Rolling of 7075 Aluminum Alloy, J. Manuf. Process., 2022, 80, p 132–140.

K. Jacobus, R. DeVor, and S. Kapoor, Machining-Induced Residual Stress: Experimentation and Modeling, Manuf. Sci. Eng., 2000, 122, p 20–31.

D. Ulutan, B.E. Alaca, and I. Lazoglu, Analytical Modelling of Residual Stresses in Machining, J. Mater. Process. Technol., 2007, 183, p 77–87.

X. Ji, X. Zhang and S.Y. Liang, Predictive Modeling of Residual Stress in Minimum Quantity Lubrication Machining, Int. J. Adv. Manuf. Technol., 2014, 70, p 2159–21684.

C. Shan, M. Zhang, S. Zhang, and J. Dang, Prediction of Machining-Induced Residual Stress in Orthogonal Cutting of Ti6Al4V, Int. J. Adv. Manuf. Technol., 2020, 107, p 2375–2385.

Y. Huang and S. Liang, Modelling of the Cutting Temperature Distribution Under the Tool Flank Wear Effect, Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci., 2003, 217, p 1195–1208.

R. Komanduri and Z.B. Hou, Thermal Modeling of the Metal Cutting Process: Part I—Temperature Rise Distribution Due to Shear Plane Heat Source, Int. J. Mech. Sci., 2000, 42, p 1715–1752.

P.L.B. Oxley and M.C. Shaw, Mechanics of Machining: An Analytical Approach to Assessing Machinability, J. Appl. Mech., 1990, 57, p 253.

G.R. Johnson and W.H. Cook, Fracture Characteristics of Three Metals Subjected to Various Strains, Strain Rates, Temperatures and Pressures, Eng. Fract. Mech., 1985, 21, p 31–48.

B. Li, Research on Analytical Prediction of Cutting Forces in Stainless Steel Machining, Huazhong University of Science and Technology, Huazhong, 2012.

D.J. Waldorf, A Simplified Model for Ploughing Forces in Turning, J. Manuf. Processes, 2006, 8, p 76–82.

W. Zhang, X. Wang, Y. Hu, and S. Wang, Predictive Modelling of Microstructure Changes, Micro-Hardness and Residual Stress in Machining of 304 Austenitic Stainless Steel, Int. J. Mach. Tools Manuf, 2018, 130–131, p 36–48.

S. Agrawal and S.S. Joshi, Analytical Modelling of Residual Stresses in Orthogonal Machining of AISI4340 Steel, J. Manuf. Process., 2013, 15, p 167–179.

A.I. Lurie, Theory of Elasticity, Springer Science & Business Media, UK, 2010.

M.T.A. Saif, C.Y. Hui, and A.T. Zehnder, Interface Shear Stresses Induced by non-Uniform Heating of a Film on a Substrate, Thin Solid Films, 1993, 224, p 159–167.

J.-C. Su, Residual Stress Modeling in Machining Processes, Georgia Institute of Technology, Georgi, 2006.

D. McDowell, An Approximate Algorithm for Elastic-Plastic Two-Dimensional Rolling/Sliding Contact, Wear, 1997, 211, p 237–246.

R. M’Saoubi, J.C. Outeiro, B. Changeux, J.L. Lebrun, and A.M. Dias, Residual Stress Analysis in Orthogonal Machining of Standard and Resulfurized AISI 316L Steels, J. Mater. Process. Technol., 1999, 96, p 225–233.

Y. Jiang and H. Sehitoglu, An Analytical Approach to Elastic-Plastic Stress Analysis of Rolling Contact, J. Tribol., 1994, 116(3), p 577–587. https://doi.org/10.1115/1.2928885

G. Olson and M. Cohen, A Mechanism for the Strain-Induced Nucleation of Martensitic Transformations, J. Less Common Metals, 1972, 28, p 107–118.

R. Zaera, J.A. Rodríguez-Martínez, A. Casado, J. Fernandez-Saez, A. Rusinek, and R. Pesci, A Constitutive Model for Analyzing Martensite Formation in Austenitic Steels Deforming at High Strain Rates, Int. J. Plast., 2012, 29, p 77–101.

F. Zhou, Research on Machined Surface Characteristics of 304 Stainless Steel, Huazhong University Science Technology, Huazhong, 2014, p 15–24

W. Zhang, H. Wu, S. Wang, Y. Hu, K. Fang, and X. Wang, Investigation of Stress Corrosion Cracking Initiation in Machined 304 Austenitic Stainless Steel in Magnesium Chloride Environment, J. Mater. Eng. Perform., 2020, 29, p 191–204.

A. Thakur and S. Gangopadhyay, State-of-the-Art in Surface Integrity in Machining of Nickel-Based Super Alloys, Int. J. Mach. Tools Manuf, 2016, 100, p 25–54.

C. Ezilarasan, V. Senthil Kumar, and A. Velayudham, Effect of Machining Parameters on Surface Integrity in Machining Nimonic C-263 Super Alloy Using Whisker-Reinforced Ceramic Insert, J. Mater. Eng. Perform., 2013, 22, p 1619–1628.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant No. 52205148), the China Postdoctoral Science Foundation (Grant No. 2023M731392), the Natural Science Foundation of Hubei Province of China (Grant No. 2023AFB928) and the Scientific Research Project of Hubei Provincial Department of Education (Grant No. Q20239404). The authors thank the Advanced Manufacturing and Technology Experiment Center of School of Mechanical Science and Engineering of HUST for residual stress measurements.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical issue of the Journal of Materials Engineering and Performance on Residual Stress Analysis: Measurement, Effects, and Control. The issue was organized by Rajan Bhambroo, Tenneco, Inc.; Lesley Frame, University of Connecticut; Andrew Payzant, Oak Ridge National Laboratory; and James Pineault, Proto Manufacturing on behalf of the ASM Residual Stress Technical Committee.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, W., Dong, H., Li, Y. et al. Effects of Processing Parameters and Tool Geometric Parameters on Residual Stress of Machined 304 Stainless Steel. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09569-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09569-2