Abstract

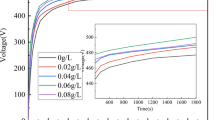

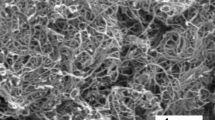

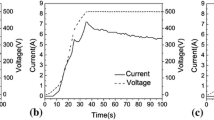

The plasma electrolytic oxidation (PEO) technology was used to prepare ceramic coating on the surface of titanium alloy to prevent the galvanic corrosion of AH36/TC4(PEO). The results showed that after PEO treatment, ceramic coating with micropores was formed on the substrate surface. When the voltage was low, the pore size was small. With the increase of voltage, the thickness and the pore sizes of the coating increased. After PEO process, the average galvanic corrosion rate was reduced by 60%, and the number of pitting pits on the AH36 surface in the galvanic pair was reduced. The tensile strength and elongation of AH36 coupled with TC4(PEO) decreased by 4.0% and 11.9%, respectively. The contents of the corrosion products Fe2O3·H2O and FeO(OH) decreased, and the corrosion area of the tensile specimen was evidently reduced. Therefore, the PEO process can effectively reduce the galvanic corrosion susceptibility of AH36/TC4(PEO), alleviate the reduction degree of ductility and toughness of anode AH36, and enhance the corrosion resistance performance.

Similar content being viewed by others

References

S.K. Yan, G.L. Song, Z.X. Li et al., A State-of-the-art Review on Passivation and Biofouling of Ti and its Alloys in Marine Environments, J. Mater. Sci. Technol., 2018, 34(3), p 421–435.

J.Z. Hu, H. Huang, P.C. Deng et al., Galvanic Corrosion Behavior of Titanium-clad Steel Plate in the Marine Environment, Mater. Corros., 2022, 73, p 887–896.

H. Ju, J.Z. Duan, Y.F. Yang et al., Mapping the Galvanic Corrosion of Three Coupled Metal Alloys Using Coupled Multielectrode Array: Influence of Chloride Ion Concentration, Mater., 2018, 11(4), p 634.

M. Scendo and K. Staszewska-Samson, Effect of Surface Modification on Corrosion Resistance of Uncoated and DLC Coated Stainless Steel Surface, J. Mater. Eng. Perform., 2017, 26, p 3946–3953.

F.C. Lupu, C. Munteanu, S. Müftü et al., Evaluation of the Wear Properties and Corrosion Resistance of 52100 Steel Coated with Ni/CrC by Cold Spraying, Coatings, 2024, 14(1), p 145.

Y.L. Hu, Z.Q. Wang, J.Y. Ai et al., Preparation of Coating on the Titanium Surface by Micro-arc Oxidation to Improve Corrosion Resistance, Coatings, 2021, 11(2), p 230.

Y.H. Ma, P. Wu, J.H. Mei et al., Effects of Micro-Arc Oxidation Surface Treatment on the Corrosion Resistance of Ti-6Al-4V Electron-Beam-Welded Joints, Metals, 2023, 13(7), p 1161.

J. Liang, S.Q. Liu, Z.J. Peng et al., Galvanic Corrosion Behavior of AZ31 Mg Alloy Coupled with Mild Steel: Effect of Coatings, J. Mater. Res. Technol., 2023, 24, p 7745–7755.

Z. Yin, R.H. He, Y. Chen et al., Effects of Surface Micro–galvanic Corrosion and Corrosive Film on the Corrosion Resistance of AZ91–xNd Alloys, Appl. Surf. Sci., 2021, 536, p 147761.

Q. Jiang, X. Ma, Y. Li et al., Corrosion Behaviour of AZ80 Mg/beryllium–bronze–alloy Galvanic Couples in Typical Marine Environment, Mater. Sci. Technol., 2016, 32(15), p 1613–1618.

A. Patnaik, X. Shan, M. Adams et al., Isolating Corrosion of Steel Plates Coupled with Titanium, Adv. Steel Constr., 2014, 10(2), p 216–233.

R. Li, L. Liu, Y. Cui et al., Corrosion Behavior of Ti60 Alloy Under Continuous NaCl Solution Spraying at 600 °C, J. Mater. Sci. Technol., 2022, 124, p 86–101.

Q. Liu, H.X. Xu, H.Q. Yin et al., Corrosion Behaviour of 316 Stainless Steel in NaCl-KCl-MgCl2 Salt Vapour at 700 °C, Corros. Sci., 2022, 194, p 109921.

K. Xiao, C.F. Dong, X.G. Li et al., Corrosion Products and Formation Mechanism During Initial Stage of Atmospheric Corrosion of Carbon Steel, J. Iron. Steel Res. Int., 2008, 15(5), p 42–48.

G.Y. Koga, D. Travessa, G. Zepon et al., Corrosion Resistance of Pseudo-high Entropy Fe-containing Amorphous Alloys in Chloride-rich Media, J. Alloys Compd., 2021, 884, p 161090.

Y.Y. Guo, J.Q. Xue, J.T. Zhang et al., Effect of Corrosion Products on the Inhibitory Performance of Imidazolium Ionic Liquid Toward Carbon Steel in CO2-saturated NaCl Brine, Colloids Surf. A, 2022, 651, p 129135.

L.J. Shi, X.Y. Yang, Y.W. Song et al., Effect of Corrosive Media on Galvanic Corrosion of Complicated Tri-metallic Couples of 2024 Al alloy/Q235 Mild Steel/304 Stainless Steel, J. Mater. Sci. Technol., 2019, 35, p 1886–1893.

L. Pastierovičová, L. Kuchariková, E. Tillová et al., Effect of Different Chloride Environments on Corrosion Behavior of Secondary AlSi7Mg0.6 Cast Alloy with Higher Fe Content, Mater. Today Proc., 2022, 62, p 2450–2456.

Y.W. Liu, M.R. Liu, X. Lu et al., Effect of Temperature and Ultraviolet Radiation on Corrosion Behavior of Carbon Steel in High Humidity Tropical Marine Atmosphere, Mater. Chem. Phys., 2022, 277, p 124962.

M.X. Guo, J.R. Tang, C. Peng et al., Effects of Salts and its Mixing Ratio on the Corrosion Behavior of 316 Stainless Steel Exposed to a Simulated Salt-lake Atmospheric Environment, Mater. Chem. Phys., 2022, 276, p 125380.

Y.M. Fan, W. Liu, S.M. Li et al., Evolution of Rust Layers on Carbon Steel and Weathering Steel in High Humidity and Heat Marine Atmospheric Corrosion, J. Mater. Sci. Technol., 2020, 39, p 190–199.

Ph. Refait, A.M. Grolleau, M. Jeannin et al., Localized Corrosion of Carbon Steel in Marine Media: Galvanic Coupling and Heterogeneity of the Corrosion Product Layer, Corros. Sci., 2016, 111, p 583–595.

H. Chen, L. Lu, Y.H. Huang et al., Insight into TiN Inclusion Induced Pit Corrosion of Interstitial Free Steel Exposed to Aerated NaCl Solution, J. Mater. Res. Technol., 2021, 13, p 13–24.

H.M. Jin, D.J. Blackwood, Y. Wang et al., First-principles Study of Surface Orientation Dependent Corrosion of BCC Iron, Corros. Sci., 2022, 196, p 110029.

A.R. Patil and S.T. Vagge, Hot Corrosion Behaviour of Inconel 738 Superalloy in Presence of NaCl, Na2SO4, V2O5, Mater. Today Proc., 2022, 65, p 74–80.

J.D. Zuo, Z.C. Peng, B.Q. Dong et al., In situ Growth of Corrosion Resistant Mg-Fe Layered Double Hydroxide Film on Q235 Steel, J. Colloid Interface Sci., 2022, 610, p 202–212.

P.A. Kamble, P.P. Deshpande, and S.T. Vagge, Numerical Investigation of Galvanic Corrosion Between Galvanized Steel and Mild Steel in Bolted Joint, Mater. Today: Proc., 2022, 50, p 1923–1929.

R.E. Melchers, Long-term Corrosion of Cast Irons and Steel in Marine and Atmospheric Environments, Corros. Sci., 2013, 68, p 186–194.

S.X. Li and L.H. Hihara, In situ Raman Spectroscopic Study of NaCl Particle-Induced Marine Atmospheric Corrosion of Carbon Steel, J. Electrochem. Soc., 2012, 159(4), p C147–C154.

Y. Wang, X. Mu, J.H. Dong et al., Insight into Atmospheric Corrosion Evolution of Mild Steel in a Simulated Coastal Atmosphere, J. Mater. Sci. Technol., 2021, 76, p 41–50.

N.S. Palsson, K. Wongpinkaew, P. Khamsuk et al., Outdoor Atmospheric Corrosion of Carbon Steel and Weathering Steel Exposed to the Tropical-coastal Climate of Thailand, Mater. Corros., 2020, 71(6), p 1019–1034.

X.Z. Ma, L.D. Meng, X.K. Cao et al., Investigation on the Initial Atmospheric Corrosion of Mild Steel in a Simulated Environment of Industrial Coastland by Thin Electrical Resistance and Electrochemical Sensors, Corros. Sci., 2022, 204, p 110389.

I.-J. Park, S.-M. Lee, M. Kang et al., Pitting Corrosion Behavior in Advanced High Strength Steels, J. Alloys Compd., 2015, 619, p 205–210.

S. Hastuty, A. Nishikata, and T. Tsuru, Pitting Corrosion of Type 430 Stainless Steel Under Chloride Solution Droplet, Corros. Sci., 2010, 52, p 2035–2043.

G.C. Qin, S.H. Xu, D.Q. Yao et al., Study on the Degradation of Mechanical Properties of Corroded Steel Plates Based on Surface Topography, J. Constr. Steel Res., 2016, 125, p 205–217.

Y.F. Wang, J.G. Li, L. Zhang et al., Structure of the Rust Layer of Weathering Steel in A High Chloride Environment: A Detailed Characterization via HRTEM, STEM-EDS, and FIB-SEM, Corros. Sci., 2020, 177, p 108997.

Y.T. Ma, Y. Li, and F.H. Wang, The Atmospheric Corrosion Kinetics of Low Carbon Steel in a Tropical Marine Environment, Corros. Sci., 2010, 52, p 1796–1800.

A. Ruiz-Garcia, E. Jimenez-Gonzalez, E. Cano et al., The Corrosion Products in a Carbon Steel/aluminum Alloy Galvanic Couple Under Thin Electrolyte Films: An Efficient Model, Electrochem. Commun., 2019, 104, p 106485.

L.Y. Zhu, Z.Y. Cui, H.Z. Cui et al., The Effect of Applied Stress on the Crevice Corrosion of 304 Stainless Steel in 3.5 wt.% NaCl Solution, Corros. Sci., 2022, 196, p 110039.

Acknowledgments

The authors acknowledge the financial supports by the youth innovation team of engine key component material research, development and application in Shaanxi Universities (K20220185), the Key R & D project of Shaanxi Province (Grant No. 2022GY-404), Natural Science Foundation of Shandong Province (Grant No. ZR2021ME041) and Xi 'an Science and technology plan project (Grant No. 23GXFW0036).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, X., Guo, Q., Jin, H. et al. Study on Galvanic Corrosion Behavior of AH36 Steel and TC4 Alloy Processed by Plasma Electrolytic Oxidation. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09535-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09535-y