Abstract

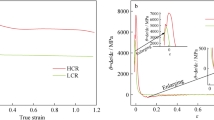

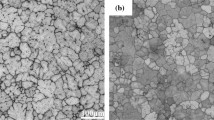

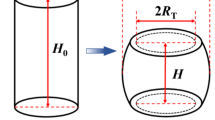

The hot deformation behavior of a novel high-Zn containing Al-Zn-Mg-Cu-Zr alloy was investigated by isothermal compression tests under the conditions of 350-500 °C and 0.0001-10 s−1. Arrhenius constitutive model and diffusion model were established to describe the flow behavior. Meanwhile, the microstructure evolution and the effect of the Zener-Hollomon parameter on dynamic recrystallization (DRX) behavior was investigated. The results show that both the Arrhenius model and diffusion model describe the flow behaviors well and the Arrhenius model shows better prediction ability. Microstructure characterization indicates that dynamic recovery (DRV) is the main dynamic softening mechanism during the entire hot deformation process, and the DRX mechanism varies at different deformation conditions. Discontinuous dynamic recrystallization and continuous dynamic recrystallization are the main DRX mechanisms under the deformation condition with moderate and low ln Z values, respectively. Moreover, at an extremely low strain rate (0.0001 s−1), the enhancement of DRV and particle pinning effect diminish the driving force for DRX at elevated temperature, resulting in a slight decrease in the proportion of DRX grain.

Similar content being viewed by others

Reference

J.C. Williams and E.A. Starke, Progress in Structural Materials for Aerospace Systems, Acta Mater., 2003, 51, p 5775–5799.

P.A. Rometsch, Y. Zhang, and S. Knight, Heat Treatment of 7xxx Series Aluminum Alloys-Some recent Developments, Trans. Nonferrous Metal. Soc., 2014, 24, p 2003–2017.

Q.H. Zang, H.M. Chen, Y.S. Lee, H.S. Yu, M.S. Kim, and H.W. Kim, Improvement of Anisotropic Tensile Properties of Al-7.9Zn-2.7Mg-2.0Cu Alloy Sheets by Particle Stimulated Nucleation, J. Alloys Compd., 2020, 828, p 154330.

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, and B. Baroux, Influence of Alloy and Heat Treatment on Precipitate Composition in Al-Zn-Mg-Cu Alloys, Acta Mater., 2010, 58, p 248–260.

J. Buha, R.N. Lumley, and A.G. Crosky, Secondary Ageing in an Aluminum Alloy 7050, Mater. Sci. Eng. A, 2008, 492, p 1–10.

D.M. Liu, B.Q. Xiong, F.G. Bian, Z.H. Li, X.W. Li, Y.G. Zhang, Q.S. Wang, G.L. Xie, F. Wang, and H.W. Liu, Quantitative Study of Nanoscale Precipitates in Al-Zn-Mg-Cu Alloys with Different Chemical Compositions, Mater. Sci. Eng. A, 2015, 639, p 245–251.

G. Sha and A. Cerezo, Characterization of Precipitates in an Aged 7xxx Series Al Alloy, Surf. Interface Anal., 2004, 36, p 564–568.

S.J. Zhang, O.Y. Kontsevoi, A.J. Freeman, and G.B. Olson, First Principles Investigation of Zinc-Induced Embrittlement in An Aluminum Grain Boundary, Acta Metall., 2011, 59, p 6155–6167.

J. Tang, J.H. Teng, J. Teng, G. Wang, D.F. Fu, H. Zhang, and F.L. Jiang, Effect of Zn Content on the Dynamic Softening of Al-Zn-Mg-Cu Alloys During Hot Compression Deformation, Vacuum, 2021, 184, p 109941.

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals And alloys in Hot Working, Mater. Des., 2011, 32, p 1733–1759.

D. Feng, X.M. Zhang, S.D. Liu, and Y.L. Deng, Constitutive Equation and Hot Deformation Behavior of Homogenized Al-7.68Zn-2.12Mg-1.98Cu-0.12Zr Alloy During Compression at Elevated Temperature, Mater. Sci. Eng. A, 2014, 608, p 63–72.

M.C. Dixit, N. Srivastava, and S.K. Rajput, Modeling of Flow Stress of AA6061 Under Hot Compression Using Artificial Neural Network, Mater. Today Proc., 2017, 4, p 1964–1971.

S.H. Liu, Q.L. Pan, H. Li, Z.Q. Huang, K. Li, X. He, and X.Y. Li, Characterization of Hot Deformation Behavior and Constitutive Modeling of Al-Mg-Si-Mn-Cr Alloy, J. Mater. Sci., 2019, 54, p 4366–4383.

C.Q. Huang, J. Deng, S.X. Wang, and L.L. Liu, A Physical-Based Constitutive Model to Describe the Strain-Hardening and Dynamic Recovery Behaviors of 5754 Aluminum Alloy, Mater. Sci. Eng. A, 2017, 699, p 106–113.

Y.C. Lin, X.M. Chen, D.X. Wen, and M.S. Chen, A Physically-Based Constitutive Model for a Typical Nickel-Based Superalloy, Comput. Mater. Sci., 2014, 83, p 282–289.

J.M. Cabrera, A.A. Omar, J.M. Prado, and J.J. Jonas, Modeling the Flow Behavior of a Medium Carbon Microalloyed Steel Under Hot Working Conditions, Metall. Mater. Trans. A, 1997, 28, p 2233–2244.

X.D. Wang, Q.L. Pan, S.W. Xiong, and L.L. Liu, Prediction on Hot Deformation Behavior of Spray Formed Ultra-High Strength Aluminum Alloy-A Comparative Study Using Constitutive Models, J. Alloys Compd., 2018, 735, p 1931–1942.

B. Li, Q.L. Pan, and Z.M. Yin, Microstructural Evolution and Constitutive Relationship of Al-Zn-Mg Alloy Containing Small Amount of Sc and Zr During Hot Deformation Based on Arrhenius-Type and Artificial Neural Network Models, J. Alloys Compd., 2014, 584, p 406–416.

Q.Y. Yang, Z.H. Deng, Z.Q. Zhang, Q. Liu, Z.H. Jia, and G.J. Huang, Effects of Strain Rate on Flow Stress Behavior and Dynamic Recrystallization Mechanism of Al-Zn-Mg-Cu Aluminum Alloy During Hot Deformation, Mater. Sci. Eng. A, 2016, 662, p 204–213.

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions, Prog. Mater. Sci., 2014, 60, p 130–207.

J.C. Li, X.D. Wu, L.F. Cao, B. Liao, Y.C. Wang, and Q. Liu, Hot Deformation and Dynamic Recrystallization in Al-Mg-Si Alloy, Mater Charact, 2021, 173, p 110976.

K. Huang and R.E. Loge, A Review of Dynamic Recrystallization Phenomena in Metallic Materials, Mater. Des., 2016, 111, p 548–574.

J.Y. Jiang, F. Jiang, H.F. Huang, M.H. Zhang, Z.Q. Tang, and M.M. Tong, Hot Deformation Analysis and Microstructure Evolution of Al-Mg-Mn-Sc-Zr Alloy by Isothermal Compression, J. Alloys Compd., 2021, 858, p 157655.

Y.J. Ban, Y. Zhang, Y.L. Jia, B.H. Tian, A.A. Volinsky, X.H. Zhang, Q.F. Zhang, Y.F. Geng, Y. Liu, and X. Li, Effects of Cr Addition on the Constitutive Equation and Precipitated Phases of Copper Alloy During Hot Deformation, Mater. Des., 2020, 191, p 108613.

Y.C. Lin, L.T. Li, Y.C. Xia, and Y.Q. Jiang, Hot Deformation and Processing Map of a Typical Al-Zn-Mg-Cu Alloy, J. Alloys Compd., 2013, 550, p 438–445.

A. Thomas, M. El-Wahabi, J.M. Cabrera et al., High Temperature Deformation of Inconel 718, J. Mater. Process. Technol., 2006, 177, p 469–472.

H.L. Wei, G.Q. Liu, and M.H. Zhang, Physically Based Constitutive Analysis to Predict Flow Stress of Medium Carbon and Vanadium Microalloyed Steels, Mater. Sci. Eng. A, 2014, 602, p 127–133.

S.H. Liu, Q.L. Pan, M.J. Li, X.D. Wang, X. He, X.Y. Li, Z.W. Peng, and J.P. Lai, Microstructure Evolution and Physical-Based Diffusion Constitutive Analysis of Al-Mg-Si Alloy During Hot Deformation, Mater. Des., 2019, 184, p 108181.

H.J. Frost and M.F. Ashby, Deformation-Mechanism Maps: The Plasticity and Creep of Metals and Ceramics, Vol 9 Pergamon Press, Oxford, 1984, p 224–225

S. Wang, J.R. Luo, L.G. Hou, J.S. Zhang, and L.Z. Zhuang, Physically Based Constitutive Analysis and Microstructural Evolution of AA7050 Aluminum Alloy During Hot Compression, Mater. Des., 2016, 107, p 277–289.

C.L. Xu, J.W. Huang, F.Q. Jiang, and Y.G. Jiang, Dynamic Recrystallization and Precipitation Behavior of a Novel Sc, Zr Alloyed Al-Zn-Mg-Cu Alloy During Hot Deformation, Mater Charact, 2022, 183, p 111629.

Y. Zhang, J.F. Jiang, Y. Wang, Y.Z. Liu, and M.J. Huang, Hot Deformation Behavior and Microstructure Evolution of Hot-Extruded 6A02 Aluminum Alloy, Mater Charact, 2022, 188, p 111908.

Q.H. Zang, H.S. Yu, Y.S. Lee, M.S. Kim, and H.W. Kim, Hot Deformation Behavior and Microstructure Evolution of Annealed Al-7.9Zn-2.7Mg-2.0Cu (wt%) Alloy, J. Alloys Compd., 2018, 763, p 25–33.

J. Luo, M.Q. Li, and D.W. Ma, The Deformation Behavior and Processing Maps in the Isothermal Compression of 7A09 Aluminum Alloy, Mater. Sci. Eng. A, 2012, 532, p 548–557.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242, Metall. Mater. Trans, 1984, 15, p 1883–1892.

Y.V.R.K. Prasad and T. Seshacharyulu, Processing Maps for Hot Working of Titanium Alloys, Mater. Sci. Eng. A, 1998, 243, p 82–88.

S. Ding, S.A. Khan, and J. Yanagimoto, Flow Behavior and Dynamic Recrystallization Mechanism of A5083 Aluminum Alloys with Different Initial Microstructures During Hot Compression, Mater. Sci. Eng. A, 2020, 787, p 139522.

H. Li, Y.C. Huang, and Y. Liu, Dynamic Recrystallization Mechanisms of As-forged Al-Zn-Mg-(Cu) Aluminum Alloy During Hot Compression Deformation, Mater. Sci. Eng. A, 2023, 878, p 145236.

X.Y. Yang, H. Miura, and T. Sakai, Continuous Dynamic Recrystallization in a Superplastic 7075 Aluminum Alloy, Mater. Trans., 2002, 43, p 2400–2407.

H.L. Yan, X. Zhao, N. Jia, Y.R. Zheng, and T. He, Influence of Shear Banding on the Formation of Brass-type Textures in Polycrystalline fcc Metals with Low Stacking Fault Energy, J. Mater. Sci. Technol., 2014, 30, p 408–416.

Acknowledgments

The research is under the support of the Department of Material Science and Engineering, Central South University, Changsha, China; and the Major Special Projects of Hunan Province (No. 2023GK1080).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that we have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Long, M., Jiang, F., Wu, F. et al. Hot Deformation Behavior and Microstructure Evolution of a Novel High-Zn Containing Al-Zn-Mg-Cu-Zr Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09506-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09506-3