Abstract

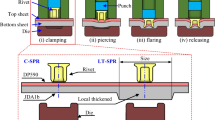

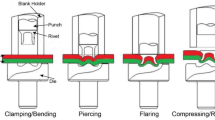

As a plastic deformation connection technology, self-piercing riveting (SPR) has wide applications in the reliable joining of lightweight alloy sheets in the automotive industry. The deformation behavior and mechanical property of SPR structure are significantly dependent on the geometric structure and dimension of rivets. In this paper, the three-layer AA5052 aluminum alloy SPR samples are fabricated with tubular rivets and semi-tubular rivets of different heights. The forming qualities as well as mechanical properties of SPR samples under different joint configurations are characterized using cross-section parameters, and tensile and axial tension-tension fatigue tests. The joint failure modes of the SPR samples under tensile and cyclic loads are also investigated. The results evidence that as the rivet height increases, the undercut and the rivet spread are increased, while the remaining bottom thickness is decreased. High-strength AA5052 aluminum alloy SPR joints can be obtained using the tubular rivet. The tensile strengths of SPR samples with 8 and 9 mm height tubular rivets are superior to the semi-tubular rivet joints, and the optimal tensile strength can be obtained using the 9 mm tubular rivet. The tensile failures of the three-layer AA5052 sheet SPR samples are the complete detachment of rivet tails from the bottom sheets. The fatigue life of the tubular rivet joints increases with the increased rivet height. The formation of macroscopic cracks in the bottom sheet is the main fatigue failure mode of the joints, and the macroscopic cracks are generated in the fretting wear areas between the rivet foot and sheets.

Similar content being viewed by others

References

F. Sato and T. Nakata, Analysis of the Impact of Vehicle Lightweighting on Recycling Benefits Considering Life Cycle Energy Reductions, Resour. Conserv. Recycl., 2021, 164, 105118.

X.H. Zhu, Y.C. Lin, Q. Wu, and Y.Q. Jiang, Effects of Aging on Precipitation Behavior and Mechanical Properties of a Tensile Deformed Al-Cu Alloy, J. Alloy. Compd., 2020, 843, 155975.

Y.H. Yao, L.J. Jing, S.L. Wang, G.Y. Li, J.J. Cui, X.H. Tang, and H. Jiang, Mechanical Properties and Joining Mechanisms of Al-Fe Magnetic Pulse Welding by Spot form for automotive Application, J. Manuf. Process., 2022, 76, p 504–517.

M.R. Khosravani, P. Soltani, and T. Reinicke, Effects of Steps on the Load Bearing Capacity of 3D-Printed Single Lap Joints, J. Mater. Res. Technol., 2023, 23, p 1834–1847.

H.B. Xia, B.Y. Yang, J.H. Su, Y.F. Liu, X. Su, C. Wang, X. Qiang, T. Wu, and C.W. Tan, Improvement of Laser Welded TC4/CFRTP Joint Strength by Combination of Surface Modification of MAO and Laser Texturing, Thin Walled Struct., 2024, 196, 111409.

G. Meschut, V. Janzen, and T. Olfermann, Innovative and Highly Productive Joining Technologies for Multi-material Lightweight Car Body Structures, J. Mater. Eng. Perform., 2014, 23, p 1515–1523.

H.B. Xia, B.Y. Yang, Y.D. Han, L.Y. Xu, C.W. Tan, L.Q. Li, H.Y. Li, X.Y. Zhao, K.P. Zhang, X. Su, P.H. Geng, and N.S. Ma, Toward Understanding the Fractured Mechanism in Laser Welded–Brazed Al/Steel Interface by in–Situ SEM Tensile Observations, J. Mater. Process. Tech., 2024, 325, 118294.

S. Das and R.G. Narayanan, Friction Stir Spot Welding of Aluminum and Steel Sheets Using a Consumable Sheet, Int. J. Adv. Manuf. Tech., 2023, 128, p 221–241.

B. Asati, N. Shajan, K.S. Arora, and R.G. Narayanan, A Comparative Investigation on Self-piercing Riveting and Resistance Spot Welding of Automotive Grade Dissimilar Galvanized Steel Sheets, Int. J. Adv. Manuf. Tech., 2022, 123, p 1079–1097.

B. Asati, N. Shajan, and K.S. Arora, Performance Evaluation of Self-piercing Riveted and Resistance Spot Welded Dissimilar Steel Joints, ARAI J. Mob. Technol., 2021, 1, p 34–42.

M. Luis, M. Rafael, and A. Paulo, A New Deformation Assisted Joining Process for Connecting Tubes to Stronger Tubesheets, Thin Walled Struct., 2022, 173, 108975.

M. Luis, M. Rafael, T. Patric, and A. Paulo, Double-Sided Self-pierce Riveting of Dissimilar Materials, Int. J. Adv. Manuf. Tech., 2021, 115, p 3679–3687.

H. Zhao, L. Han, Y.P. Liu, and X.P. Liu, Automatic and Robust Design for Multiple Self-piercing Riveted Joints Using Deep Neural Network, Int. J. Adv. Manuf. Tech., 2022, 122, p 947–975.

Z. Xue, Z. Yang, C. Xu, Z. Chen, Z. Wang, Q. Zhou, J. Liu, and L. Li, An Improved Simplified Model of Self-piercing Riveted Joints for Predicting Quasi-Static Mechanical Behavior of Steel–Aluminum Hybrid Components, J. Manuf. Process., 2023, 108, p 457–474.

B. Bader, J. Altach, E. Türck, and T. Vietor, Approach for Assessment of Suitable Automotive Component Ranges for the Application of Multi Material Design, Procedia CIRP, 2020, 91, p 188–193.

N. Karathanasopoulos, K.S. Pandya, and D. Mohr, An Experimental and Numerical Investigation of the Role of Rivet and Die Design on the Self-piercing Riveting Joint Characteristics of Aluminum and Steel Sheets, J. Manuf. Process., 2021, 69, p 290–302.

Y.W. Ma, M. Lou, Y.B. Li, and Z.Q. Lin, Effect of Rivet and Die on Self-piercing Rivetability of AA6061-T6 and Mild Steel CR4 of Different Gauges, J. Mater. Process. Tech., 2017, 251, p 282–294.

Y.P. Liu, H. Li, H. Zhao, and X.P. Liu, Effects of the Die Parameters on the Self-piercing Riveting Process, Int. J. Adv. Manuf. Tech., 2019, 105, p 3353–3368.

Z.P. Du, L.B. Duan, L.J. Jing, A.G. Cheng, and Z.C. He, Numerical Simulation and Parametric Study on Self-piercing Riveting Process of Aluminium-Steel Hybrid Sheets, Thin Walled Struct., 2021, 164, 107872.

R. Haque, Quality of Self-piercing Riveting (SPR) Joints from Cross-Sectional Perspective: A Review, Arch. Civ. Mech. Eng., 2018, 181, p 83–93.

K. Mori, Y. Abe, and T. Kato, Self-pierce Riveting of Multiple Steel and Aluminum Alloy Sheets, J. Mater. Process. Tech., 2014, 214, p 2002–2008.

D. Heidrich, F. Zhang, and X.F. Fang, Fatigue Strength of Rivet Resistance Spot Welding Technique in Comparison with Self-piercing Riveting for Multi-material Body-In-White Structure, J. Mater. Eng. Perform., 2021, 30, p 3806–3821.

J. Arakawa, W. Jinnouchi, H. Akebono, and A. Sugeta, Effect of Pre-water Immersion Period on Fatigue Resistance of Adhesive Bonded Thin Steel, Int. J. Fatigue, 2023, 174, 107725.

Y.C. Lin, G.D. Pang, Y.Q. Jiang, X.G. Liu, X.Y. Zhang, C. Chen, and K.C. Zhou, Hot Compressive Deformation Behavior and Microstructure Evolution of a Ti-55511 Alloy with Basket-Weave Microstructures, Vacuum, 2019, 169, 108878.

L. Deng, M. Lou, Y.B. Li, and B. Carlson, Thermally Assisted Self-piercing Riveting of AA6061-T6 to Ultrahigh Strength Steel, J. Manuf. Sci. Eng., 2019, 141, 101006.

Z.C. Huang, Y.K. Zhang, Y.C. Lin, and Y.Q. Jiang, Physical Property and Failure Mechanism of Self-piercing Riveting Joints Between Foam Metal Sandwich Composite Aluminum Plate and Aluminum Alloy, J. Mater. Res. Technol., 2022, 17, p 139–149.

B.Y. Xing, F. Tang, C.Y. Song, and X.C. He, Static and Fatigue Behavior of Self-piercing Riveted Joints with Two Overlap Areas, J. Mater. Res. Technol., 2021, 14, p 1333–1338.

N. Hoang, R. Porcaro, M. Langseth, and A. Hanssen, Self-piercing Riveting Connections Using Aluminium Rivets, Int. J. Solids Struct., 2010, 47, p 427–439.

J. Moraes, H. Rao, J. Jordon, and M. Barkey, High Cycle Fatigue Mechanisms of Aluminum Self-Piercing Riveted Joints, Fatigue Fract. Eng. Mater. Struct., 2017, 41, p 57–70.

Y.I. Lee and H.K. Kim, Effects of Residual Stresses on the Fatigue Lifetimes of Self-Piercing Riveted Joints of AZ31 Mg Alloy and Al5052 Al Alloy Sheets, Metals, 2021, 11, p 2037–2057.

X.L. Zhang, X.C. He, B.Y. Xing, L. Zhao, Y. Lu, F.S. Gu, and A. Ball, Influence of Heat Treatment on Fatigue Performances for Self-piercing Riveting Similar and Dissimilar Titanium, Aluminium and Copper Alloys, Mater. Design, 2016, 97, p 108–117.

Z.C. Huang, Z.J. Zhou, and Y.Q. Jiang, Effect of Shot Peening on Static and Fatigue Properties of Self-piercing Riveting Joints, J. Mater. Res. Technol., 2022, 18, p 1070–1080.

Y. Abe, T. Maeda, D. Yoshioka, and K. Mori, Mechanical Clinching and Self-pierce Riveting of Thin Three SHEETS of 5000 series Aluminum Alloy and 980 Mpa Grade Cold Rolled Ultra-High Strength Steel, Materials, 2020, 13, p 13214741.

N. Ma and H. Murakawa, Numerical and Experimental Study on Nugget Formation in Resistance Spot Welding for Three Pieces of High Strength Steel Sheets, J. Mater. Process. Tech., 2010, 14, p 2045–2052.

S. Achira, Y. Abe, and K.L. Mori, Self-pierce Riveting of Three Thin Sheets of Aluminum Alloy A5052 and 980 MPa Steel, Materials, 2022, 15, p 15031010.

N.Z. Borba, J. Körbelin, B. Fiedler, J.F. dos Santos, and S.T. Amancio-Filho, Low-Velocity Impact Response of Friction Riveted Joints for Aircraft Application, Mater. Design, 2020, 186, 108369.

Y.L. Jia, Z.C. Huang, Y.C. Zhang, and F. Zhang, Forming Quality and Fatigue Behavior of Self-piercing Riveted Joints of DP590 and AA6061 Plates, Adv. Mater. Sci. Eng., 2021, 2021, p 4381544.

M. Lou, Y.B. Li, Y. Wang, B. Wang, and X.M. Lai, Influence of Resistance Heating on Self-piercing Riveted Dissimilar Joints of AA6061-T6 and Galvanized DP590, J. Mater. Process. Tech., 2014, 214, p 2119–2126.

G. Du, Y. Xing, and X. Li, Fatigue Properties of Self-piercing Riveted Multi-rivet Joints in Steel and Aluminum Sheets, Mater. Sci. Eng. Technol., 2019, 50, p 1495–1502.

Z.C. Huang, G.H. Huang, F.W. Shan, Y.Q. Jiang, Y.Q. Zou, and X.Y. Nie, Forming Quality and Microstructure Evolution of AA6061-T6 Aluminum Alloy Joint During Flow Drill Screwing Process, Adv. Eng. Mater., 2023, 25, p 2300054.

L. Han, A. Chrysanthou, and K. Young, Mechanical Behaviour of Self-piercing Riveted Multi-layer Joints Under Different Specimen Configurations, Mater. Design, 2006, 28, p 2024–2033.

Y.P. Liu, L. Han, H. Zhao, and X.P. Liu, Evaluation and Correction of Cutting Position’s Effects on Quality Indicator Measurement of Self-piercing Riveted Joint, Mater Design, 2021, 202, 109583.

Y. Liu and W.M. Zhuang, Self-piercing Riveted-Bonded Hybrid Joining of Carbon Fibre Reinforced Polymers and Aluminium Alloy Sheets, Thin Walled Struct., 2019, 144, 106340.

O. Çavuşoğlu, A. Bakırcı, H. Dinkçi, and A.G. Yılmazoğlu, Triple Joining of Different Sheets with Self-pierce Riveting Method, Sci. Technol. Weld. Join., 2022, 27, p 579–585.

H. Tian, B.Y. Xing, H.S. Zhang, K.W. Wang, K. Zeng, and X.C. He, A Study on Non-destructive Testing of Geometrical Parameters of Self-piercing Riveting Joints Using an Acoustic Microscope with a Scanning Focusing Converter, Nondestruct. Test Eval., 2022, 38, p 1–14.

Z.F. Shi, Y.L. Li, T. Suo, Y.Y. Liu, N. Zeng, and X.D. Liu, Influence of Loading Frequency on the High Cycle Fatigue Properties of Metallic And Alloy, J. Mater. Sci. Eng., 2009, 27, p 488–492.

S.E. Stanzl-Tschegg and H. Mayer, Fatigue and Fatigue Crack Growth of Aluminium Alloys at Very High Numbers of Cycles, Int. J. Fatigue, 2001, 23, p 231–237.

Z.C. Huang, Y.L. Jia, Y.Q. Jiang, and Y.C. Zhang, Mechanical Properties and Fatigue Failure Mechanisms of Purely Self-piercing Riveted (SPR) and Hybrid (SPR-Bonded) Joints Under Salt Spray Environment, J. Mater. Res. Technol., 2022, 20, p 2501–2517.

S.M. Wan, S. Hu, S.Y. Li, L.H. Zhang, and X.Q. Liu, Process Parameters and Joint Evaluation of Self-piercing Riveting with Half-Hollow Rivets, J. Tianjin Univ., 2007, 40, p 495–498.

B. Asati, R.G. Narayanan, N. Shajan, and K.S. Arora, Effect of Die Design and Sheet Placement on Self-piercing Rivet of Automotive Steels and Comparison with Resistance Spot and Friction Stir Spot Welding, J. Mater. Eng. Perform., 2023, 32, p 8913–8926.

S. Gupta, R.G. Narayanan, S. Das, and B Asati. Joining of Dissimilar Galvanized Steel Sheets by Resistance Spot Welding and Self-piercing Riveting. Adv. Addit. Manuf. Metal Join., 2023, p 381–393.

Z.J. Zhou, Z.C. Huang, Y.Q. Jiang, and N.L. Tang, Joining Properties of SPFC440/AA5052 Multi-Material self-piercing Riveting Joints, Materials, 2022, 15, p 15092962.

Z.J. Zhou, Z.C. Huang, and S.J. Li, Numerical Simulation and experimental Study on self-piercing Riveted AA5052/SPFC440 Dissimilar Metals, J. East China Jiaotong Univ., 2022, 39, p 84–93.

D.Z. Li, A. Chrysanthou, I. Patel, and G. Williams, Self-piercing Riveting-a Review, Int. J. Adv. Manuf. Tech., 2017, 92, p 1777–1824.

Q.A. Hua, An Overview of Self-piercing Riveting Process with Focus on Joint Failures, Corrosion Issues and Optimisation Techniques, Chin. J. Mech. Eng.-En., 2021, 34, p 100–124.

M.A. Karim, T.E. Jeong, W. Noh, K.Y. Park, D.H. Kam, C. Kim, D.G. Nam, H. Jung, and Y.D. Park, Joint Quality of Self-piercing Riveting (SPR) and Mechanical Behavior Under the Frictional Effect of Various Rivet Coatings, J. Manuf. Process., 2020, 58, p 466–477.

J.R. Duan and C. Chen, Effect of Edge Riveting on the Failure Mechanism and Mechanical Properties of Self-piercing Riveted Aluminium Joints, Eng. Fail. Anal., 2023, 150, 107305.

Z.Q. Xie, W.M. Yan, Y. Cheng, T.T. Mu, and L.L. Song, Improved Shear Strength Design of Cold-Formed Steel Connection with Single Self-piercing Rivet, Thin Walled Struct., 2018, 131, p 708–717.

W.M. Yan, Z.Q. Xie, L.L. Song, and H.X. He, Study on the Mechanical Property of Self-piercing Rivet and its Constitutive Model in Cold-Formed Thin-Walled Steel, Eng. Mech., 2017, 34, p 133–143.

Y.L. Jia, Z.C. Huang, and Y.Q. Jiang, Low-Speed Impact and Residual Mechanical Performance of the BR1200HS/AA6082 Self-piercing Riveted Joints, Metals, 2023, 13, p 1800.

Z.C. Huang, N.L. Tang, Y.Q. Jiang, and Q. Zhang, Effect of Repeated Impacts on the Mechanical Properties of Nickel Foam Composite Plate/AA5052 Self-piercing Riveted Joints, J. Mater. Res. Technol., 2023, 23, p 4691–4701.

K. Nikolaos and M. Dirk, Strength and Failure of Self-piercing Riveted Aluminum and Steel Sheet Joints: Multi-axial Experiments and Modeling, J. Adv. Res., 2022, 5, 100107.

J. Mucha, The Failure Mechanics Analysis of the Solid Self-Piercing Riveting Joints, Eng. Fail. Anal., 2015, 47, p 77–88.

J. Presse, B. Künkler, and T. Michler, Stress-Based Approach for Fatigue Life Calculation of Multi-material Connections Hybrid Joined by Self-piercing Rivets and Adhesive, Thin Walled Struct., 2020, 159, 107192.

J. Presse, T. Michler, and B. Künkler, Fatigue Life Performance of Multi-material Connections Hybrid Joined by Self-piercing Rivets and Adhesive, Mater. Test, 2020, 62, p 973–978.

H. Jiang, S. Gao, G.Y. Li, and J.J. Cui, Structural Design of Half Hollow Rivet for Electromagnetic Self-piercing Riveting Process of Dissimilar Materials, Mater. Design, 2019, 183, p 1–10.

L. Huang, J. Bonnen, J. Lasecki, H.D. Guo, and X.M. Su, Fatigue and Fretting of Mixed Metal Self-piercing Riveted Joint, Int. J. Fatigue, 2016, 83, p 230–239.

Y.C. Zhang, Z.C. Huang, Y.Q. Jiang, and Y.L. Jia, Mechanical Properties of B1500HS/AA5052 Joints by Self-Piercing Riveting, Metals, 2023, 13, p 328.

X.L. Zhang, X.C. He, W.J. Wei, J.W. Lu, and K. Zeng, Fatigue Characterization and Crack Propagation Mechanism of Self-piercing Riveted Joints in Titanium Plates, Int. J. Fatigue, 2020, 134, p 105465.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 52375333), the Major Scientific and Technological Achievements Ripening and Engineering Research Projects of Jiangxi province (Grant No. 20232AEI92001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest regarding the submission and publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, ZC., Zhang, YC. & Jiang, YQ. Forming Qualities and Mechanical Properties of AA5052 Aluminum Alloy Self-piercing Riveted Joints Connected by Tubular and Semi-tubular Rivets. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09497-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09497-1