Abstract

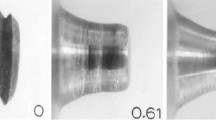

Friction stir welding (FSW) of dissimilar metals and polymers has shown some attractive applications in industrial fields such as drone tails and automotive parts. Adjusting process parameters is a fast and effective method to improve the tensile performance of joints. In this paper, the evaluation of friction stir lap welded joints between 6061-T6 aluminum alloy and carbon fiber reinforced thermoplastic (CFRTP) is conducted by studying the microstructure characteristics of the weld interface, SEM of the fracture surface, tensile and hardness analysis. The results indicate that the upper part of the weld cross-section joint experiences longer stirring and friction durations. The small metal fragments broken at the lower part of the joint are recombined into larger fragments. At high rotational speeds, the formation of welds is faster and more uniform. Metal fragments are further broken and refined and the molten CFRTP is uniformly mixed with Al alloy fragments in the stirring zone, which improvs the bonding property between two materials. Therefore, the value of tensile strength at 1800 rpm reaches 32.9 MPa, which is equivalent to 63.1% of CFRTP sheets.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this manuscript.

References

Y. Huang, X. Meng, Y. Xie, Z.L. Long Wan, J Cao Lv, and J.C. Feng, Friction Stir Welding/Processing of Polymers and Polymer Matrix Composites, Compos. Part A Appl. Sci. Manuf., 2018, 105, p 235–257. https://doi.org/10.1016/j.compositesa.2017.12.005

S. Aliasghari, M. Ghorbani, P. Skeldon, H. Karami, and M. Movahedi, Effect of Plasma Electrolytic Oxidation on Joining of AA 5052 Aluminum Alloy to Polypropylene using Friction Stir Spot Welding, Surf. Coat. Technol., 2017, 313, p 274–281. https://doi.org/10.1016/j.surfcoat.2017.01.084

Ke. Chen, B. Chen, S. Zhang, M. Wang, L. Zhang, and A. Shan, Friction Spot Welding Between Porous TC4 Titanium Alloy and Ultra High Molecular Weight Polyethylene, Mater. Des., 2017, 132, p 178–187. https://doi.org/10.1016/j.matdes.2017.06.071

E. Majid and A.D. Hamed, Experimental and Thermomechanical Study on FSW of PMMA Polymer T-Joint, Int. J. Adv. Manuf. Technol., 2018, 97, p 1445–1456. https://doi.org/10.1007/s00170-018-1847-7

X. Meng, Y. Huang, J. Cao, J.J. Shen, and J.F. dos Santos, Recent Progress on Control Strategies for Inherent Issues in Friction Stir Welding, Prog. Mater Sci., 2021, 115, p 100706. https://doi.org/10.1016/j.pmatsci.2020.100706

X. Meng, Y. Xie, S. Sun, X.T. Ma, L. Wan, J. Cao, and Y.X. Huang, Lightweight Design: Friction-Based Welding between Metal and Polymer, Acta Metall. Sin. (Eng. Lett.), 2023, 36, p 1–18. https://doi.org/10.1007/s40195-023-01552-5

Y.Y. Jang, J.C. Ha, D. Lee, Y. Lee, S.Y. Nam, S.B. Yang, and D.J. Kwon, Dissimilar Material Bonding Technology for Lightweight Future Mobility: A Review, Polym. Testing, 2023, 129, p 108281. https://doi.org/10.1016/j.polymertesting.2023.108281

H. Shahmiri, M. Movahedi, and A.H. Kokabi, Friction Stir Lap Joining of Aluminum Alloy to Polypropylene Sheets, Sci. Technol. Weld. Joining, 2017, 22(2), p 120–126. https://doi.org/10.1080/13621718.2016.1204171

A.R. Patel, D.J. Kotadiya, J.M. Kapopara, C.G. Dalwadi, N.P. Patel, and H.G. Rana, Investigation of Mechanical Properties for Hybrid Joint of Aluminum to Polymer Using Friction Stir Welding (FSW), Materials Today: Proceedings, 2018, 5(2), p 4242–4249. https://doi.org/10.1016/j.matpr.2017.11.688

F. Khodabakhshi, M. Haghshenas, S. Sahraeinejad et al., Microstructure-Property Characterization of a Friction Stir Welding Welded Joint Between AA5059 Aluminum Alloy and High Density Polyethylene, Mater. Charact., 2014, 98, p 73–82. https://doi.org/10.1016/j.matchar.2014.10.013

H.A. Derazkola and A. Simchi, An Investigation on the Dissimilar Friction Stir Welding of T-Joints Between AA5754 Aluminum Alloy and Poly (Methyl Methacrylate), Thin-Walled Structures, 2019, 135, p 376–384. https://doi.org/10.1016/j.tws.2018.11.027

W. Ratanathavorn and A. Melander, Dissimilar Joining Between Aluminum Alloy (AA 6111) and Thermoplastics Using Friction Stir Welding, Sci. Technol. Weld. Joining, 2015, 20(3), p 222–228. https://doi.org/10.1179/1362171814Y.0000000276

K. Nagatsuka, S. Yoshida, A. Tsuchiya. and K. Nakata, Direct Joining of Carbon-Fiber–Reinforced Plastic to an Aluminum Alloy Using Friction Lap Joining, Compos. B Eng., 2015, 73, p 82–88. https://doi.org/10.1016/j.compositesb.2014.12.029

Y. Sun, Y. Zhang, H. Long, Y. Sun, Li. Zou. and X. Yang, Friction Stir Lap Welding for Dissimilar Materials of Aluminum Alloy and Carbon-Fiber-Reinforced Polyetherimide, Mater. Today Commun., 2022, 33, p 104427. https://doi.org/10.1016/j.mtcomm.2022.104427

S. Swaminathan, K. Oh-Ishi, A.P. Zhilyaev et al., Peak Stir Zone Temperatures During Friction Stir Processing, Metall. and Mater. Trans. A., 2010, 41, p 631–640. https://doi.org/10.1007/s11661-009-0140-7

Y. Li, X. Bi, M. Xu et al., Optimization of Friction Lap Joining Parameters and Exploration Connection Mechanism of CFRPA6/6061-T6 Aluminum Alloy Hybrid Structures, Compos. Struct., 2023, 325, p 117566. https://doi.org/10.1016/j.compstruct.2023.117566

N. Goswami and K. Pal, Comparative Assessment on Weldability of Al 6061 to Polycarbonate for Dissimilar Sheets Placement in Friction Stir Lap Welding Using Sensor Signals, Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci., 2022, 236(7), p 3474–3496. https://doi.org/10.1177/09544062211042663

A.N. Ashong, M. Lee, S.T. Hong et al., Refill Friction Stir Spot Welding of Dissimilar AA6014 Al Alloy and Carbon-Fiber-Reinforced Polymer Composite, Met. Mater. Int., 2021, 27, p 639–649. https://doi.org/10.1007/s12540-020-00788-5

C. Ochoa-Putman and U.K. Vaidya, Mechanisms of Interfacial Adhesion in Metal–Polymer Composites–Effect of Chemical treatment, Compos. A Appl. Sci. Manuf., 2011, 42(8), p 906–915. https://doi.org/10.1002/mawe.201200943

Funding

This work was supported by the National Science Foundation of China (52005071, 51875072), Natural Science Foundation of Liaoning Province (2022-MS-342), and Liaoning Provincial Department of Education General Project (LJKZ0478).

Author information

Authors and Affiliations

Contributions

YZ: Conceptualization, Writing original draft; YS: Investigation, Methodology; HL: Supervision, Resources; JZ: Validation; LZ: Supervision, Resources; XY: Project administration. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuan, Z., Sun, Y., Long, H. et al. Study on the Microstructure and Mechanical Properties on Al/Carbon Fiber Reinforced Thermoplastic Dissimilar Friction Stir Lap Welding Joints. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09482-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09482-8