Abstract

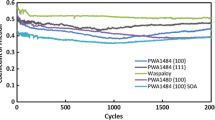

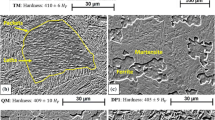

The high-temperature wear behavior of a Haynes 282® superalloy was studied at 625 °C in pin-on-roll sliding tests with a load of 68 N for 7.5 km using pins of the alloy in heat-treated (T) and wrought (W) conditions. Specific wear rate plots as a function of the sliding distance indicate that wear was more significant for up to 3.8 km for heat-treated specimens (T); however, wear of the alloys in both metallurgical conditions gave similar values, which did not increase from 5.0 km onwards. Characterization of the wear mechanisms suggests that metallic wear was present, expressed as the plastic deformation at the surface and subsurface regions of the alloys in both conditions. Oxidational wear was also found, which was more important for the W alloy. Nevertheless, the mixture of oxides and metallic particles favored the formation of tribofilms that reduced friction and prevented further wear. Tribofilms were also developed on the surface of the counter rolls, and particles from them were transferred to the surface of the nickel alloy pins by adhesion.

Similar content being viewed by others

References

W. Betteridge and S.W.K. Shaw, Development of Superalloys, Mater. Sci. Technol., 1987, 3, p 682–694.

T.M. Pollock and S. Tin, Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure, and Properties, J. Propul. Power, 2006, 22(3), p 61–374.

K.Y. Shin, J.H. Kim, M. Terner, B.O. Kong, and H.U. Hong, Effects of Heat Treatment on the Microstructure Evolution and The High-Temperature Tensile Properties of Haynes 282 Superalloy, Mater. Sci. Eng. A, 2019, 751, p 311–322.

J. Saarimäki, J.J. Moverare, and M.H. Colliander, Time-and Cycle-Dependent Crack Propagation in Haynes 282®, Mater. Sci. Eng. A, 2016, 658, p 463–471.

S. Hanke, A. Fischer, and F.F. dos Santos, Sliding Wear Behaviour of a Cr-Base Alloy After Microstructure Alterations Induced by Friction Surfacing, Wear, 2015, 338, p 332–338.

N.K. Arakere and G. Swanson, Fretting Stresses in Single Crystal Superalloy Turbine Blade Attachments, J. Tribol., 2001, 123(2), p 413–423.

J.T. Berry, Some Friction and Lubrication Problems in the Metalworking of the Superalloys, J. Tribol., 1975, 97(1), p 33–36.

J. Krell, A. Röttger, and W. Theisen, Chromium-Nickel-Alloys for Wear Application at Elevated Temperature, Wear, 2019, 432, p 102924.

H.A. Abdel-Aal, On the Influence of Thermal Properties on Wear Resistance of Rubbing Metals at Elevated Temperatures, J. Tribol., 2000, 122(3), p 657–660.

J.L. Lawen Jr., S.J. Calabrese, and O.S. Dinc, Wear Resistance of Super Alloys at Elevated Temperatures, J. Tribol., 1998, 120(2), p 339–344.

Z. Xu, Z. Huang, J. Zhang, X. Xu, P. Li, F. Su, and M. Zhu, Tribological Behaviors and Microstructure Evolution of Inconel 718 Superalloy at Mid-High Temperature, J. Mater. Res. Technol., 2021, 14, p 2174–2184.

L. Li, K. He, S. Sun, W. Yang, Z. Yue, and H. Wan, High-Temperature Friction and Wear Features of Nickel-Based Single Crystal Superalloy, Tribol. Lett., 2020, 68, p 1–12.

K. Feng and T. Shao, The Evolution Mechanism of Tribo-oxide Layer during High Temperature Dry Sliding Wear for Nickel-Based Superalloy, Wear, 2021, 476, p 203747.

F. Bayata and A.T. Alpas, The High Temperature Wear Mechanisms of Iron-Nickel Steel (NCF 3015) and Nickel Based Superalloy (Inconel 751) Engine Valves, Wear, 2021, 480, p 203943.

J.H. Ramírez-Ramírez, J.M. Alvarado-Orozco, F.A. Pérez-González, R. Colás, and N.F. Garza-Montes-de-Oca, Influence of Heat Treatment on the Wear Behavior of a Haynes 282® Nickel-Based Superalloy, J. Tribol., 2019, 141(4), p 041606.

N.F. Garza-Montes-de-Oca and W.M. Rainforth, Wear Mechanisms Experienced by a Work Roll Grade High Speed Steel under Different Environmental Conditions, Wear, 2009, 267(1–4), p 441–448.

O.A. Zambrano, J.J. Coronado, and S.A. Rodríguez, Tempering Temperature Effect on Sliding Wear at High Temperatures in Mottled Cast Iron, Tribol. Lett., 2015, 57(2), p 19.

O.A. Zambrano, K.F. Gallardo, D.M. Polania, S.A. Rodríguez, and J.J. Coronado, The Role of the Counterbody’s Oxide on the Wear Behavior of HSS and Hi-Cr, Tribol. Lett., 2018, 66, p 1–14.

J. Zhang and A.T. Alpas, Delamination Wear in Ductile Materials Containing Second Phase Particles, Mater. Sci. Eng. A, 1993, 160(1), p 25–35.

N.P. Suh, The Delamination Theory of Wear, Wear, 1973, 25, p 111–124.

F.P. Bowden and D. Tabor, The Friction and Lubrication of Solids, Vol 1 Oxford University Press, 2001.

F.H. Stott and G.C. Wood, The Influence of Oxides on the Friction and Wear of Alloys, Tribol. Int., 1978, 11(4), p 211–218.

T.F.J. Quinn, Review of Oxidational Wear: Part I: The Origins of Oxidational Wear, Tribol. Int., 1983, 16(5), p 257–271.

T.F.J. Quinn, Oxidational Wear Modelling Part III. The Effects of Speed and Elevated Temperatures, Wear, 1998, 216(2), p 262–275.

I. Hutchings and P. Shipway, Tribology: Friction and Wear of Engineering Materials, Butterworth-Heinemann, 2017.

F.A. Pérez-González, N.F. Garza-Montes-de Oca, and R. Colás, High Temperature Oxidation of the Haynes 282© Nickel-Based Superalloy, Oxid. Met., 2014, 82, p 145–161.

F.A. Pérez-González, J.H. Ramírez-Ramírez, M. Terock, N.F. Garza-Montes-de-Oca, U. Glatzel, and R. Colás, High-Temperature Oxidation of a Nickel Base Superalloy at Different Oxygen Partial Pressures, Corros. Eng. Sci. Technol., 2016, 51(7), p 513–521.

R.N. Nnaji, M.A. Bodude, L.O. Osoba, O.S.I. Fayomi, and F.E. Ochulor, Study on High-Temperature Oxidation Kinetics of Haynes 282 and Inconel 718 Nickel-Based Superalloys, Int. J. Adv. Manuf. Technol., 2020, 106, p 1149–1160.

G.R. Fox and H. Liang, Wear Mode Comparison of High-Performance Inconel Alloys, J. Tribol., 2010, 132(2), p 021603.

S.S. Saleem and M.F. Wani, Tribological Characterization of N 80A and 21–4N Valve Materials Against GGG-40 Seat Material under Dry Sliding Conditions at Temperatures up to 500 C, J. Tribol., 2017, 139(6), p 061605.

S.R. Bhagavatula and R. Komanduri, On Chemomechanical Polishing of Si3N4 with Cr2O3, Philos. Mag. A, 1996, 74(4), p 1003–1017.

L.F. Chekhomova, Abrasive Properties of Modified Chromia, Inorg. Mater., 2001, 37, p 274–280.

W. Su, S. Niu, Y. Huang, C. Wang, Y. Wen, X. Li, C. Deng, C. Deng, and M. Liu, Friction and Wear Properties of Plasma-Sprayed Cr2O3-BaCrO4 Coating at Elevated Temperatures, Ceram. Int., 2022, 48(6), p 8696–8705.

Acknowledgments

The authors thank CONAHCYT-México, PRODEP-México, and FIME-UANL-México for the assistance given to perform this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ramírez-Ramírez, J.H., Pineda-Arriaga, K.Y., Gaona-Martínez, M.J. et al. Hot Wear of a Haynes 282® Superalloy. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-09081-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09081-z