Abstract

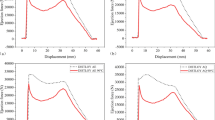

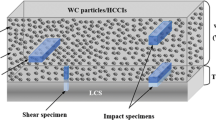

Deformation processing techniques (cold rolling, extrusion and drawing) are used as main manufacturing methods at both industrial and laboratory level—especially for metallic components. Cold working triggers several microstructural phenomena which eventually assist strain-induced strengthening. Recently, deformation processing has extended from conventional strengthening method to a strategic step in fabrication of state-of-the-art modern composites. For example, the in situ synthesis of new improved phases using powder metallurgy requires the powder particles to be arranged in a favorable position, so that the phase synthesis could initiate. This study investigates the codeformation aspects of ceramic (B4C, 1-7 µm) and metallic (Fe, 45 µm) microparticle mixtures (Fe-5, 10 and 15 vol.% B4C), when they are subjected to cold rolling (η = 0.82, 1.24, 1.79, 2.10 and 3.10). While on the one side the inter-particle physical interactions are complemented upon, a methodology is also developed for dealing with deformation-induced microstructural phenomena of the powder mixtures. Results showed that while cold working induces irreversible morphological changes in the Fe particles, the presence of B4C ceramic particles becomes significant only at higher deformation levels.

Similar content being viewed by others

References

H.M.N. Zafar and F. Nair, Deformation Processed High Strength High Conductivity Cu and Al Matrix Composite Wires: An Introductory Review, Proc. Inst. Mech. Eng. L-J MAT, 2022, 236, p 1927–1948. https://doi.org/10.1177/14644207221090534

D. Raabe, Deformation Processing, Encyclopedia of Condensed Matter Physics. F. Bassani, G.L. Liedl, P. Wyder Ed., Elsevier, Oxford, 2005, p 387–395

P. Rokebrand and I. Sigalas, Fe-B-C Composites Produced Using Spark Plasma Sintering, Int. J. Refract. Hard Met., 2015, 49, p 320–326. https://doi.org/10.1016/j.ijrmhm.2014.07.039

M. Fattahi et al., Strengthening of Novel TiC-AlN Ceramic with in-situ Synthesized Ti3Al Intermetallic Compound, Ceram. Int., 2020, 46, p 14105–14113. https://doi.org/10.1016/j.ceramint.2020.02.213

I. Montealegre-Melendez et al., Analysis of the Microstructure and Mechanical Properties of Titanium-Based Composites Reinforced by Secondary Phases and B4C Particles Produced via Direct Hot Pressing, Materials, 2017, 10, p 1240. https://doi.org/10.3390/ma10111240

V.S. Balaji and S. Kumaran, Densification and Microstructural Studies of Titanium–Boron Carbide (B4C) Powder Mixture During Spark Plasma Sintering, Powder Technol., 2014, 264, p 536–540. https://doi.org/10.1016/j.powtec.2014.05.050

I. Schramm Deschamps et al., Design of In Situ Metal Matrix Composites Produced by Powder Metallurgy—A Critical Review, Metals, 2022, 12, p 1–61. https://doi.org/10.3390/met12122073

Czahor, C.F., Anderson, I.E., Riedemann, T.M., and Russell, A.M. Deformation processed Al/Ca nano-filamentary composite conductors for HVDC applications. in 38th Riso International Symposium on Materials Science. Denmark: IOP Publishing. (2017)

Y.V. Turov et al., Structure Formation in Sintering Iron-Boron Carbide Powder Composite, Powder Metall. Met. Ceram., 1991, 30, p 465–470. https://doi.org/10.1007/BF00795069

V. Vassileva et al., The Role of the Atmosphere on Boron-Activated Sintering of Ferrous Powder Compacts, Powder Metall. Prog., 2018, 18, p 6–20. https://doi.org/10.1515/pmp-2018-0002

S. Sahin, C. Meric and S. Saritas, Production of Ferroboron Powders by Solid Boronizing Method, Adv. Powder Technol., 2010, 21, p 483–487. https://doi.org/10.1016/j.apt.2010.01.011

M. Sułowski, P. Kulecki, E. Lichańska and A. Radziszewska, Fractography and Porosity Analysis of Cr and Cr-Mo PM Steels, Arch. Metall. Mater., 2016, 61, p 1613–1622. https://doi.org/10.1515/amm-2016-0263

R.M. German, P. Suri and S.J. Park, Review: Liquid Phase Sintering, J. Mater. Sci., 2009, 44, p 1–39. https://doi.org/10.1007/s10853-008-3008-0

H.M.N. Zafar and F. Nair, Fabrication and Microscale Characterization of Iron Matrix Composite Wires Reinforced by in situ Synthesized Iron Boride Phases, Arab. J. Sci. Eng., 2022, 48, p 3909–3930. https://doi.org/10.1007/s13369-022-07320-4

Y.V. Turov et al., Gas Transport Processes in Sintering of an Iron-Boron Carbide Powder Composite, Sov. Powder Metall. Met. Ceram., 1989, 28, p 618–622. https://doi.org/10.1007/BF00794577

J.M.C. Azevedo, A.C. Serrenho and J.M. Allwood, The Deformation of Metal Powder Particles: Hardness and Microstructure, Procedia Eng., 2017, 207, p 1200–1205. https://doi.org/10.1016/j.proeng.2017.10.870

N.A. Fleck, On the Cold Compaction of Powders, J. Mech. Phys. Solids, 1995, 43, p 1409–1431. https://doi.org/10.1016/0022-5096(95)00039-L

D. Ramírez-Vinasco, C.A. León-Patiño, E.A. Aguilar-Reyes and G. Rodríguez-Ortiz, Compressibility Behaviour of Conventional AlN-Cu Mixtures and Cu-(AlN-Cu) Composite Powder Mixtures, Powder Technol., 2022, 403, p 117385. https://doi.org/10.1016/j.powtec.2022.117385

L. He and E. Ma, Processing and Microhardness of bulk Cu-Fe Nanocomposites, Nanostruct. Mater., 1996, 7, p 327–339. https://doi.org/10.1016/0965-9773(96)00003-7

E.Y. Nzoma, A. Guillet and P. Pareige, Nanostructured Multifilamentary Carbon-Copper Composites: Fabrication, Microstructural Characterization, and Properties, J. Nanomater., 2012, 2012, p 44. https://doi.org/10.1155/2012/360818

J.B. Dubois, L. Thilly, P.O. Renault and F. Lecouturier, Cu-Nb Nanocomposite Wires Processed by Severe Plastic Deformation: Effects of the Multi-Scale Microstructure and Internal Stresses on Elastic-Plastic Properties, Adv. Eng. Mater., 2012, 14, p 998–1003. https://doi.org/10.1002/adem.201200033

V. Vidal, L. Thilly, F. Lecouturier and P.O. Renault, Effects of Size and Geometry on the Plasticity of High-Strength Copper/Tantalum Nanofilamentary Conductors Obtained by Severe Plastic Deformation, Acta Mater., 2006, 54, p 1063–1075. https://doi.org/10.1016/j.actamat.2005.10.031

T. Gu et al., Multiscale Modeling of the Anisotropic Electrical Conductivity of Architectured and Nanostructured Cu-Nb Composite Wires and Experimental Comparison, Acta Mater., 2017, 141, p 131–141. https://doi.org/10.1016/j.actamat.2017.08.066

A.B. Rozhnov et al., Low-Cycle Bending Fatigue and Electrical Conductivity of High-Strength Cu/Nb Nanocomposite Wires, Int. J. Fatigue, 2019, 128, p 105188. https://doi.org/10.1016/j.ijfatigue.2019.105188

A.Y. Volkov et al., Abnormally High Strength and Low Electrical Resistivity of the Deformed Cu/Mg-Composite with a Big Number of Mg-filaments, Mater. Des., 2020, 185, p 108276. https://doi.org/10.1016/j.matdes.2019.108276

F. Moisy et al., Influence of Intermetallic Compounds on the Electrical Resistivity of Architectured Copper Clad Aluminum Composites Elaborated by a Restacking Drawing Method, Mater. Des., 2018, 155, p 366–374. https://doi.org/10.1016/j.matdes.2018.06.021

L. Tian, H. Kim, I. Anderson and A. Russell, The Microstructure-Strength Relationship in a Deformation Processed Al-Ca Composite, Mater. Sci. Eng. C, 2013, 570, p 106–113. https://doi.org/10.1016/j.msea.2013.01.062

L. Tian et al., A Deformation-Processed Al-matrix/Ca-nanofilamentary Composite with Low Density, High Strength, and High Conductivity, Mater. Sci. Eng. C, 2017, 690, p 348–354. https://doi.org/10.1016/j.msea.2017.03.010

K. Xu et al., Characterization of Strength and Microstructure in Deformation Processed Al-Mg Composites, J. Mater. Sci., 1999, 34, p 5955–5959. https://doi.org/10.1023/a:1004772526480

A.M. Russell et al., A High-Strength, High-Conductivity Al-Ti Deformation Processed Metal Metal Matrix Composite, Compos. Part A Appl., 1999, 30, p 239–247. https://doi.org/10.1016/S1359-835X(98)00163-8

K. Xu, K. Wongpreedee and A.M. Russell, Microstructure and Strength of a Deformation Processed Al-20%Sn in situ Composite, J. Mater. Sci., 2002, 37, p 5209–5214. https://doi.org/10.1023/A:1021092001147

V.F. Tkachenko and Y.I. Kogan, Structural Characteristics and Mechanical Properties of Sintered Fe-B4C Materials, Sov. Powder Metall. Met. Ceram., 1978, 17, p 384–388. https://doi.org/10.1007/BF00795022

S. Guk, W. Müller, K. Pranke and R. Kawalla, Mechanical Behaviour Modelling of an Mg-Stabilized Zirconia Reinforced TRIP-Matrix-Composite Under Cold Working Conditions, Mater. Sci. Appl., 2014, 5, p 812. https://doi.org/10.4236/msa.2014.511081

F. Nair and M. Hamamcı, Effect of In-Situ Synthesized Boride Phases on the Impact Behavior of Iron-Based Composites Reinforced by B4C Particles, Metals, 2020, 10, p 1–22. https://doi.org/10.3390/met10050554

W. Zhang, A Review of Tribological Properties for Boron Carbide Ceramics, Prog. Mater. Sci., 2021, 116, p 100718. https://doi.org/10.1016/j.pmatsci.2020.100718

W. Zhang, S. Yamashita and H. Kita, Progress in Pressureless Sintering of Boron Carbide Ceramics—A Review, Adv. Appl. Ceram., 2019, 118, p 222–239. https://doi.org/10.1080/17436753.2019.1574285

P.H. Shipway and I.M. Hutchings, The Influence of Particle Properties on the Erosive Wear of Sintered Boron Carbide, Wear, 1991, 149, p 85–98. https://doi.org/10.1016/0043-1648(91)90366-3

D. Raabe, F. Heringhaus, U. Hangen and G. Gottstein, Investigation of a Cu-20 Mass% Nb in situ Composite Pt 1 Fabrication, Microstructure and Mechanical Properties, Int. J. Mater. Res., 1995, 86, p 405–415. https://doi.org/10.1515/ijmr-1995-860606

V.I. Pantsyrny et al., Thermal Stability of the High Strength High Conductivity Cu-Nb, Cu-V, and Cu-Fe Nanostructured Microcomposite Wires, IEEE Trans. Appl. Supercond., 2014, 24, p 1–4. https://doi.org/10.1109/TASC.2013.2293655

J.D. Verhoeven et al., Development of Deformation Processed Copper-Refractory Metal Composite Alloys, J. Mater. Eng., 1990, 12, p 127–139. https://doi.org/10.1007/bf02834066

D. Farkas et al., Image Analysis: A Versatile Tool in the Manufacturing and Quality Control of Pharmaceutical Dosage Forms, Pharmaceutics, 2021, 13, p 1–22. https://doi.org/10.3390/pharmaceutics13050685

S.M. Hartig, Basic Image Analysis and Manipulation in ImageJ, Curr. Protoc. Mol. Biol., 2013, 102, p 14–15. https://doi.org/10.1002/0471142727.mb1415s102

T. Zheng, K. Yang and X. Wang, Quick Measurement of all Filaments’ Diameters in E-glass Yarn by Image-Pro Plus, J. Ind. Text., 2022, 51, p 1376–1396. https://doi.org/10.1177/152808371990

L. Deng et al., Effects of Interface Area Density and Solid Solution on the Microhardness of Cu-Nb Microcomposite Wires, Mater Charact, 2019, 150, p 62–66. https://doi.org/10.1016/j.matchar.2019.02.002

D.A. Hardwick, C.G. Rhodes and L.G. Fritzemeier, The Effect of Annealing on the Microstructure and Mechanical Properties of Cu-X Microcomposites, Metall. Trans. A, 1993, 24, p 27–34. https://doi.org/10.1007/bf02669599

Marte, J.S., Zahrah, T., and Kampe, S.L. In Situ Multilithic Metal Matrix Composites Produced by Codeformation Processing. in 4th International Conference on Processing and Manufacturing of Advanced Materials. 2003. Barcelona, Spain: MDPI.

Funding

This study did not receive any funding.

Author information

Authors and Affiliations

Contributions

FN was involved in materials and experimental setup preparation, resources and supervision. HMNZ was responsible for conceptualization, data curation, manuscript preparation, validation and visualization.

Corresponding author

Ethics declarations

Conflict of interests

The authors confirm that they have no financial or non-financial competing interests associated with the publication of this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zafar, H.M.N., Nair, F. Quantitative Analysis of Codeformation Behavior of Ceramic and Metallic Particle System. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-09038-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09038-2