Abstract

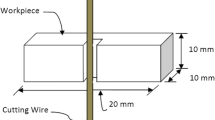

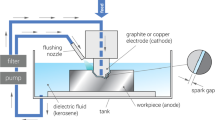

The square hole with less than 1 mm fabricated on Inconel X750 has been challenged due to the high electrode wear and poor performance measures. Hence, the research paper deals with studying the influence of different electrode sizes on performance measures (squareness: Sq. ness, material removal rate: MRR, surface roughness: SR and electrode wear length: EWL) using nano-silicon carbide (SiC) mixing electrical discharge machining (EDM) of Inconel X750. Taguchi design has been used to design the experimental work and fabricating the square hole from 0.6 to 0.9 mm side length with 0.1 mm equal interval on Inconel X750. An influence of electrode size, pulse duration, duty cycle and current on performance measures of Inconel X750 has been studied using mean response plot. The element present in worn-out electrode surfaces has been studied using EDS analysis. Modeling and surface defects have been evaluated using a Microsoft Excel and scanning electron microscope, respectively. The additive ratio assessment (ARAS) approach is used to find the optimum process parameters. An analysis reveals the carbon layer formation due to the hydrocarbon-based dielectric through pyrolysis happening in the plasma channel. The 0.6 mm square electrode produces a square hole with less deviation compared with 0.7, 0.8 and 0.9 mm square electrodes. The 0.9 mm square electrodes have low wear length compared with other square electrodes. The performance measures are enhanced by the ARAS approach by 4% for Sq. ness, 12% for MRR, 9% for SR and 11% for EWL.

Similar content being viewed by others

Data Availability

The available data and material had been used and discussed in the manuscript.

Code Availability

No code has been used in this work.

References

R.R. Panigrahi, A. Panda, A.K. Sahoo, and R. Kumar, Machining Performance Measures of High Temperature Heat Resistant Super alloys: A Review, Mater. Today: Proc., 2019, 18, p 4524–4530.

R. Choudhary, H. Garg, M. Prasad, and D. Kumar, Effect of Cryogenic Treatment of Tool Electrode on the Machining Performance and Surface Finish During Electrical Discharge Machining of Hastelloy C-4, Mater. Today: Proc., 2017, 4(2), p 1158–1166.

K. Manikandan and K. Palanikumar, Machinability Evaluation and Comparison of Incoloy 825, Inconel 603 XL, Monel K400 and Inconel 600 Super Alloys in Wire Electrical Discharge Machining, J. Mater. Res. Technol., 2020, 9(6), p 12260–12272.

J.J. Maurer, J.J. Mallett, J.L. Hudson, S.E. Fick, T.P. Moffat, and G.A. Shaw, Electrochemical Micromachining of Hastelloy B-2 with Ultrashort Voltage Pulses, Electrochim. Acta, 2010, 55(3), p 952–958.

V.S. Kannan, K. Lenin, D. Srinivasan, and D.R. Kumar, Investigation on Laser Square Hole Drilling of AA7475/SiC/ZrSiO4 Composites, SILICON, 2022, 14(9), p 4557–4574.

V. Balasubramaniam, D. Rajkumar, P. Ranjithkumar, and C.S. Narayanan, Comparative Study of Mechanical Technologies over Laser Technology for Drilling Carbon Fiber Reinforced Polymer Materials, Indian J. Eng. Mater. Sci., 2020, 27, p 19–32.

R.B. Bhosle and S.B. Sharma, Multi-Performance Optimization of Micro-EDM Drilling Process of Inconel 600 Alloy, Mater. Today: Proc., 2017, 4(2), p 1988–1997.

S.K. Basha, M. Kolli, and M.J. Raju, Parametric optimization of EDM on Hastelloy C-276 Using Taguchi L18 Technique, Int. J. Eng. Technol., 2018, 7(27), p 714–716.

S. Plaza, J.A. Sanchez, E. Perez, R. Gil, B. Izquierdo, N. Ortega, and I. Pombo, Experimental Study on Micro EDM-Drilling of Ti6Al4V Using Helical Electrode, Precis. Eng., 2014, 38(4), p 821–827.

Z.Y. Yu, K.P. Rajurkar, and H. Shen, High Aspect Ratio and Complex Shaped Blind Micro Holes by Micro EDM, CIRP Ann., 2002, 51(1), p 359–362.

B. Ekmekci and A. Sayar, Debris and Consequences in Micro Electric Discharge Machining of Micro-Holes, Int. J. Mach. Tools Manuf, 2013, 65, p 58–67.

H.S. Liu, B.H. Yan, F.Y. Huang, and K.H. Qiu, A Study on the Characterization of High Nickel Alloy Micro-Holes Using Micro-EDM and their Applications, J. Mater. Process. Technol., 2005, 169(3), p 418–426.

M.S. Azad and A.B. Puri, Simultaneous Optimisation of Multiple Performance Characteristics in Micro-EDM Drilling of Titanium Alloy, Int. J. Adv. Manuf. Technol., 2012, 61(9–12), p 1231–1239.

P.C. Kaminski and M.N. Capuano, Micro Hole Machining by Conventional Penetration Electrical Discharge Machine, Int. J. Mach. Tools Manuf, 2003, 43(11), p 1143–1149.

M. Ay, U. Çaydaş and A. Hasçalık, Optimization of Micro-EDM Drilling of Inconel 718 Superalloy, Int. J. Adv. Manuf. Technol., 2013, 66(5–8), p 1015–1023.

Y.H. Jeong and B.K. Min, Geometry Prediction of EDM-Drilled Holes and Tool Electrode Shapes of Micro-EDM Process Using Simulation, Int. J. Mach. Tools Manuf., 2007, 47(12–13), p 1817–1826.

Y. Feng, Y. Guo, Z. Ling, and X. Zhang, Micro-Holes EDM of Superalloy Inconel 718 Based on a Magnetic Suspension Spindle System, Int. J. Adv. Manuf. Technol., 2019, 101(5–8), p 2015–2026.

D.G. Dilip, S. Panda, and J. Mathew, Characterization and Parametric Optimization of Micro-hole Surfaces in Micro-EDM Drilling on Inconel 718 Superalloy Using Genetic Algorithm, Arab. J. Sci. Eng., 2020, 45(7), p 5057–5074.

G. D’Urso and C. Ravasio, The Effects of Electrode Size and Discharged Power on Micro-Electro-Discharge Machining Drilling of Stainless Steel, Adv. Mech. Eng., 2016, 8(5), p 1687814016648646.

N. Natarajan and P. Suresh, Experimental Investigations on the Microhole Machining of 304 Stainless Steel by Micro-EDM Process Using RC-Type Pulse Generator, Int. J. Adv. Manuf. Technol., 2015, 77(9), p 1741–1750.

M.P. Jahan, Y.S. Wong, and M. Rahman, A Study on the Quality Micro-Hole Machining of Tungsten Carbide by Micro-EDM Process Using Transistor and RC-Type Pulse Generator, J. Mater. Process. Technol., 2009, 209(4), p 1706–1716.

M.D. Moses and M.P. Jahan, Micro-EDM Machinability of Difficult-to-Cut Ti-6Al-4V Against Soft Brass, Int. J. Adv. Manuf. Technol., 2015, 81(5), p 1345–1361.

M.P. Jahan, Y.S. Wong, and M. Rahman, A Comparative Experimental Investigation of Deep-Hole Micro-EDM Drilling Capability for Cemented Carbide (WC-Co) Against Austenitic Stainless Steel (SUS 304), Int. J. Adv. Manuf. Technol., 2010, 46(9), p 1145–1160.

C. Wang and Z. Qiang, Comparison of Micro-EDM Characteristics of Inconel 706 Between EDM Oil and an Al Powder-Mixed Dielectric, Adv. Mater. Sci. Eng., 2019, 2019, p 5625360.

K. Ishfaq, M.U. Waseem, and M. Sana, Investigating Cryogenically Treated Electrodes’ Performance Under Modified Dielectric (s) for EDM of Inconel (617), Mater. Manuf. Processes, 2022, 37, p 1902–1911.

P. Kuppan, S. Narayanan, A. Rajadurai, and M. Adithan, Effect of EDM Parameters on Hole Quality Characteristics in Deep Hole Drilling of Inconel 718 Superalloy, Int. J. Manuf. Res., 2015, 10(1), p 45–63.

P.V. Kumar, J. Vivek, N. Senniangiri, S. Nagarajan, and K. Chandrasekaran, A Study of Added Sic Powder in Kerosene for the Blind Square Hole Machining of CFRP Using Electrical Discharge Machining, SILICON, 2022, 14(4), p 1831–1849.

R. Khanna, N. Sharma, N. Kumar, R.D. Gupta, and A. Sharma, WEDM of Al/SiC/Ti Composite: A Hybrid Approach of RSM-ARAS-TLBO Algorithm, Int. J. Lightweight Mater. Manuf., 2022, 5(3), p 315–325.

Q. Liu, Q. Zhang, G. Zhu, K. Wang, J. Zhang, and C. Dong, Effect of Electrode Size on the Performances of Micro-EDM, Mater. Manuf. Processes, 2016, 31(4), p 391–396.

V. Muthukumar, N. Rajesh, R. Venkatasamy, A. Sureshbabu, and N. Senthilkumar, Mathematical Modeling for Radial Overcut on Electrical Discharge Machining of Incoloy 800 by Response Surface Methodology, Procedia Mater. Sci., 2014, 6, p 1674–1682.

A. Kumar, R. Vishwakarma and S.K. Yadav, Optimization of EDM process parameter for inconel 925 by using Taguchi method, Recent Advances in Manufacturing Modelling and Optimization. Springer, Singapore, 2022, p 303–312

K. Wang, Q. Zhang, G. Zhu, Y. Huang, and J. Zhang, Influence of Tool Size on Machining Characteristics of Micro-EDM, Procedia CIRP, 2018, 68, p 604–609.

G. D’Urso and C. Ravasio, The Effects of Electrode Size and Discharged Power on Micro-Electro-Discharge Machining Drilling of Stainless Steel, Adv. Mech. Eng., 2016, 8(5), p 1687814016648646. https://doi.org/10.1177/1687814016648646

Y.F. Tzeng and C.Y. Lee, Effects of Powder Characteristics on Electro discharge Machining Efficiency, Int. J. Adv. Manuf. Technol., 2001, 17(8), p 586–592.

P. Pecas and E. Henriques, Electrical Discharge Machining Using Simple and Powder-Mixed Dielectric: The Effect of the Electrode Area in the Surface Roughness and Topography, J. Mater. Process. Technol., 2008, 200(1), p 250–258.

R.V. Penmetsa, A. Ilanko, S. Rajesh et al., Experimental Study, and Machining Parameter Optimization on Powder-Mixed EDM of Nimonic 901 Using Feed-Forward Backpropagation Neural Networks, Int. J. Adv. Manuf. Technol., 2022 https://doi.org/10.1007/s00170-022-09297-8

P.S. Bains, S.S. Sidhu, H.S. Payal, and S. Kaur, Magnetic Field Influence on Surface Modifications in Powder Mixed EDM, SILICON, 2019, 11(1), p 415–423.

S.K. Sahu, T. Jadam, S. Datta, and G. Nandi, Effect of Using SiC Powder-Added Dielectric Media During Electro-Discharge Machining of Inconel 718 Superalloys, J. Braz. Soc. Mech. Sci. Eng., 2018, 40(7), p 1–19.

M. Okawa, T. Shioiri, H. Okubo, and S. Yanabu, Area Effect on Electric Breakdown of Copper and Stainless Steel Electrodes in Vacuum, IEEE Trans. Electr. Insul., 1988, 23(1), p 77–81.

P.J. Liew, J. Yan, and T. Kuriyagawa, Carbon Nanofiber Assisted Micro Electro Discharge Machining of Reaction-Bonded Silicon Carbide, J. Mater. Process. Technol., 2013, 213(7), p 1076–1087.

A. Hasçalık and U. Çaydaş, Electrical Discharge Machining of Titanium Alloy (Ti–6Al–4V), Appl. Surf. Sci., 2007, 253(22), p 9007–9016.

D. Raj Kumar, N. Jeyaprakash, C.H. Yang, and K.R. Ramkumar, Investigation on Drilling Behavior of CFRP Composites Using Optimization Technique, Arab. J. Sci. Eng., 2020, 45(11), p 8999–9014.

D. Raj Kumar, N. Jeyaprakash, C.H. Yang, and K.R. Ramkumar, Investigation on Drilling Behavior of CFRP Composites Using Optimization Technique, Arab. J. Sci. Eng., 2020, 45, p 8999–9014.

D.R. Kumar, N. Jeyaprakash, C.H. Yang, and S. Sivasankaran, Optimization of Drilling Process on Carbon-Fiber Reinforced Plastics Using Genetic Algorithm, Surf. Rev. Lett., 2021, 28(03), p 2050056.

G. Feng, X. Yang, and G. Chi, Experimental and Simulation Study on Micro Hole Machining in EDM with High-Speed Tool Electrode Rotation, Int. J. Adv. Manuf. Technol., 2019, 101(1), p 367–375.

A. Alhodaib, P. Shandilya, A.K. Rouniyar, and H. Bisaria, Experimental Investigation on Silicon Powder Mixed-EDM of Nimonic-90 Superalloy, Metals, 2021, 11(11), p 1673.

R. Manivannan and M.P. Kumar, Multi-Attribute Decision-Making of Cryogenically Cooled Micro-EDM Drilling Process Parameters Using TOPSIS Method, Mater. Manuf. Processes, 2017, 32(2), p 209–215.

M.T. Yan, K.Y. Huang, and C.Y. Lo, A Study on Electrode Wear Sensing and Compensation in Micro-EDM Using Machine Vision System, Int. J. Adv. Manuf. Technol., 2009, 42, p 1065–1073. https://doi.org/10.1007/s00170-008-1674-3

A.P. Tiwary, B.B. Pradhan, and B. Bhattacharyya, Study on the Influence of Micro-EDM Process Parameters During Machining of Ti–6Al–4V Superalloy, Int. J. Adv. Manuf. Technol., 2015, 76(1), p 151–160.

B.B. Pradhan, M. Masanta, B.R. Sarkar, and B. Bhattacharyya, Investigation of Electro-Discharge Micro-Machining of Titanium Super Alloy, Int. J. Adv. Manuf. Technol., 2009, 41(11), p 1094–1106.

A.P. Tiwary, B.B. Pradhan, and B. Bhattacharyya, Influence of Various Metal Powder Mixed Dielectric on Micro-EDM Characteristics of Ti-6Al-4V, Mater. Manuf. Processes, 2019, 34(10), p 1103–1119.

Acknowledgements

The authors thank PRIMST, Vallam, Trichy, India, for providing scanning electron microscopy facilities.

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

RK worked on conceptualization, methodology, writing, reviewing, discussion and editing, computation, methodology, software, discussion and conceptualization and analysis, writing the manuscript, methodology and software. SD and TK checked the review on the manuscript language.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Consent to Participate

All persons named as authors in this manuscript have participated in the planning, design and performance of the research, and in the interpretation of the results.

Consent for Publication

All authors have endorsed the publication of this research. The manuscript has not been published elsewhere and it has not been submitted simultaneously for publication elsewhere.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kirubagharan, R., Dhanabalan, S. & Karthikeyan, T. The Effect of Electrode Size on Performance Measures of Inconel X750 using Nano-SiC Powder Mixing Electrical Discharge Machining. J. of Materi Eng and Perform 33, 1283–1303 (2024). https://doi.org/10.1007/s11665-023-08835-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08835-z