Abstract

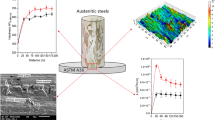

In this paper, the durability, the wear resistance, the tribological behavior, and the wear particles flow of the Anodic Aluminum Oxide Film 5083 were studied under cyclic loading. Different anodizing durations (reaction times (RT)) and applied currents (J) were tested. Besides, a tribological model with a correlation between the friction coefficient and the wear mechanisms of the oxide layer was established. Postmortem analyses were investigated using scanning electron microscopy (SEM), energy-dispersive x-rays (EDX), and profilometry analyses. Experimental results were shown that the increase in the RT improves the durability of the 5083-aluminum alloy oxide layer. Moreover, when RT increased, the stability of friction coefficient was improved, and the surfaced pores were more filled with micro-sized wear particles, inducing the establishment of a compacted layer. Consequently, the 5083-aluminum alloy oxide layer was shown important tribological characteristics such as the durability and wear resistance after hundreds of rubbing cycles. It was concluded that three stages characterized the friction behavior and the wear particle flow under cycling: firstly, a friction coefficient stable stage with the establishment of an internal flow that feeds the contact (internal source flow); the second stage is the progressive increase in the friction coefficient, while the wear particles were crushed and compacted to form a smooth layer, constituting the continuous internal flow; and the third stage is the return of the stable state of the friction coefficient, where the smooth layers spread, and the pores filled with the powder.

Similar content being viewed by others

References

P. Mukhopadhyay, Processing, and Use of AA6XXX Series Aluminium Alloys, Alloy Designation; ISRN Metallurgy, 15 (2012)

C. Chuan and A.H.W. Ngan, Theoretical Pore Growth Models for Nanoporous Alumina, Nanoporous Alum. Fabr. Struct. Prop. Appl., 2015, 219, p 31-60.

W.J. Stępniowski, A. Nowak-Stępniowska, A. Presz, T. Czujko, and R.A. Varin, The Effects of Time and Temperature on the Arrangement of Anodic Aluminum Oxide Nanopores, Mater. Charact., 2014, 91, p 1-9.

M. Abid, A. Sellami, H. Nouri, M. Kchaou, and M. Haboussi, Nano-and Micro-Scales Characterization of Anodic Oxide Layer Coating on 2017A-T4 Aluminum Alloy, Trans. Indian Inst. Met., 2021, 74(4), p 1001-1014.

M. Sepúlveda, J.G. Castaño, and F. Echeverría, Influence of Temperature and Time on the Fabrication of Self-Ordering Porous Alumina by Anodizing in Etidronic Acid, Appl. Surf. Sci., 2018, 454, p 210-217.

A. Sevgi, B. Evrim, and Y. Birgül, The Nanoporous Anodic Alumina Oxide Formed by Two-Step Anodization, Thin Solid Films, 2018, 648, p 94-102.

L. Juan, Z. Zhang, L. Yuxin, M. Yingjun, L. Chen, Z. Zhang, and S. Runguang, Self-Organization Process of Aluminum Oxide during Hard Anodization, Electrochim. Acta, 2016, 213, p 14-20.

M. Abid, H. Ben Abdelali, M. Kchaou et al., Friction Durability of Anodized Aluminum Alloy 2017A under Dry Conditions, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08065-3

M. Abid, J. Fortes da Cruz, M. Kchaou, and M. Haboussi, Micro-and Macro-Scale Characterization of the Microstructure and Scratch Resistance of the 5083-Anodic Aluminum Oxide Film, Proc. Instit. Mech. Eng. Part L J. Mater. Des. Appl., 2023, 237, p 1624-1637.

R.K. Choudhary, P. Mishra, V. Kain, K. Singh, S. Kumar, and J.K. Chakravartty, Scratch Behavior of Aluminum Anodized in Oxalic Acid: Effect of Anodizing Potential, Surf. Coat. Technol., 2015, 283, p 135-147.

H.M. Seyyed, M. Soheil, E. Mohamadreza, and K.A. Jafar, Characteristics and Tribological Behavior of the Hard Anodized 6061-T6 Al Alloy, J. Alloys Compd., 2020, 842, p 155988.

L. Gyu-Sun, C. Joohoon, Ch. Yong Chan, B. Sang Don, and L. Young-Ze, Tribological Effects of Pores on an Anodized Al Alloy Surface as Lubricant Reservoir, Current Appl. Phys., 2011, 11, p 182-186.

L. Zheng-yang, C. Zhen-bing, Y. Cui, L. Jian-hua, and Z. Min-hao, Effect of Oxidation Time on the Impact Wear of Micro-Arc Oxidation Coating on Aluminum Alloy, Wear, 2019, 426–427, p 285-295.

M. Guezmil, W. Bensalah, A. Khalladi, K. Elleuch, M. De-PetrisWery, and H.F. Ayedi, Effect of Test Parameters on the Friction Behaviour of Anodized Aluminium Alloy, Int. Sch. Res. Not., 2014, 1, p 1. https://doi.org/10.1155/2014/795745

M. Guezmil, W. Bensalah, A. Khalladi, K. Elleuch, M. Depetris-wery, and H.F. Ayedi, Friction Coefficient and Microhardness of Anodized Aluminum Alloys under Different Elaboration Conditions, Trans. Nonferrous Met. Soc. China, 2015, 25, p 1950-1960.

K. Hyo-sang, K. Dae-hyun, W. Lee, C. Seong Jai, H. Jun-Hee, and A. Hyo-Sok, Tribological Properties of Nanoporous Anodic Aluminum Oxide Film, Surf. Coat. Technol., 2010, 205, p 1431-1437.

C. Boher, R. Gras, and F. Rezai-Aria, A Wear Model Based on Cumulative Cyclic Plastic Strainin, Wear, 2009, 267(5–8), p 1087-1094.

J. Kang, Y. Lu, X. Yang, X. Zhao, Y. Zhang, and Z. Xing, Modeling and Experimental Investigation of Wear and Roughness for Honed Cylinder Liner During Running-in Process, Tribol. Int., 2022, 171, p 107531.

A. Quacquarelli, G. Mollon, T. Commeau, and N. Fillot, A Dual Numerical-Experimental Approach for Modeling Wear of Diamond Impregnated Tools, Wear, 2021, 478–479, p 203763.

C. Boher, D. Attaf, L. Penazzi, and C. Levaillant, Wear Behaviour on the Radius Portion of a Die in Deep-Drawing: Identification, Localisation and Evolution of the Surface Damage, Wear, 2005, 259(7–12), p 1097-1108.

C. Vergne, C. Boher, R. Gras, and C. Levaillant, Influence of Oxides on Friction in Hot Rolling: Experimental Investigations and Tribological Modelling, Wear, 2006, 260(9–10), p 957-975.

F. Guo, Y. Cao, K. Wang, P. Zhang, Y. Cui, Z. Hu, and Z. Xie, Effect of the Anodizing Temperature on Microstructure and Tribological Properties of 6061 Aluminum Alloy Anodic Oxide Films, Coatings, 2022, 12(3), p 314.

N. Altinkok, I. Ozsert, and F. Findik, Dry Sliding Wear Behavior of Al2O3/SiC Particle Reinforced Aluminum Based MMCs Fabricated by Stir Casting Method, Acta Phys. Pol. A, 2013, 124(1), p 11-19.

U. Soy, A. Demir, and F. Findik, Friction and Wear behaviors Al-SiC-B4C Composites Produced by Pressure Infiltration Method, Ind. Lubr. Tribol., 2011, 63(5), p 387-393.

A. Gökçe, F. Findik, and A.O. Kurt, Microstructural Examination and Properties of Premixed Al-Cu-Mg Powder Metallurgy Alloy, Mater. Charact., 2011, 67(7), p 730-735.

B. Aktaş, M. Toprak, A. Çalık, and A. Tekgüler, Effect of Pack-Boriding on the Tribological Behavior of Hardox 450 and HiTuf Steels, Rev. Adv. Mater. Sci., 2020, 59(1), p 314-321.

B. Aktas, V. Balak, and C. Carboga, Dry Sliding Wear Behavior of Boron-Doped AISI 1020 Steels, Acta Phys. Pol. A, 2017, 132, p 3.

C. Carboga, B. Aktas, and B. Kurt, Dry Sliding Wear Behavior of Boron-Doped 205 Manganese Steels, J. Mater. Eng. Perform, 2020, 29, p 3120-3126.

V.F. Steier, T. Doca, and J.A. Araujo, Fretting Wear Investigation of 1350-H19 Aluminum Wires Tested Against Treated Surfaces, Wear, 2018, 414–425, p 1-8.

M. Kchaou, R. Elleuch, Y. Desplanques, X. Boidin, and G. Degallaix, Etude du comportement de l’acier X40CrMoV5-1 pré-oxydé en frottement-usure sous faible Vitesse de glissement, Ann. Chim. Mat., 2010, 35(1), p 41-57.

Acknowledgment

The authors acknowledge the LSPM (Laboratoire des Sciences des Procédés et des Matériaux, France), LASEM (Laboratoire des Systèmes Électromécaniques, Tunisia) laboratories, and SUPMECA Paris (School of Mechanical and Manufacturing Engineering) institute for the use of their equipment. The authors are grateful to Dr Ovidi u Brinza from LSPM and to Pr Emin Bayraktar and Dr Dhurata Katundi from SUPMECA for their valuable assistance in making the microscopic observations. The authors are thankful to the deanship of scientific research at University of Bisha for supporting this work through the fast-track research support program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abid, M., Kchaou, M., Hoang, A.T. et al. Wear Mechanisms Analysis and Friction Behavior of Anodic Aluminum Oxide Film 5083 under Cyclic Loading. J. of Materi Eng and Perform 33, 1527–1537 (2024). https://doi.org/10.1007/s11665-023-08616-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08616-8