Abstract

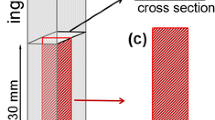

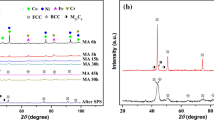

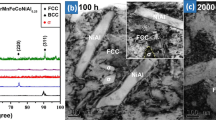

In the present work, an as-cast strip of novel high entropy alloy (Fe48.8Co26.9Cr9.7Ni5.7V8.3N0.6 at.%) was successfully produced by twin-roll casting technology. Then, the as-cast strip with or without primary annealing was cold-rolled and annealed. The directly cold-rolled and annealed samples consisted of single-phase FCC and they were easier to recrystallize. While many granular VN particles precipitated during primary annealing. Besides, after secondary annealing, the dual phases microstructure of FCC+BCC was obtained. The BCC phase made the alloy have high recrystallization resistance and inhibited grains growth, causing refined grains in secondary annealed samples. The grain size was refined to 1.26 µm when annealed at 800 °C, the corresponding recrystallization fraction was only 60.9%. When annealing at 1000 °C, the content of BCC decreased, resulting in larger grain size (~ 8.13 µm) and fully recrystallized structure. The secondary annealed sheets showed excellent tensile properties, the ultimate tensile strengths were 770-898 MPa and corresponding total elongations were 32-46%.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Q. Ding, Y. Zhang, X. Chen, X. Fu, and R.O. Ritchie, Tuning Element Distribution, Structure and Properties by Composition in High-Entropy Alloys, Nature, 2019, 574, p 223–227.

B. Cantor, I.T.H. Chang, and P. Knight, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218.

E. Abbasi and K. Dehghani, Effect of Nb-C Addition on the Microstructure and Mechanical Properties of CoCrFeMnNi High Entropy Alloys during Homogenisation, Mater. Sci. Eng. A, 2019, 753, p 224–231.

J.W. Yeh, S.K. Chen, and S.J. Lin, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299–303.

M.L. Wang, Y.P. Lu, and T.M. Wang, A Novel Bulk Eutectic High-Entropy Alloy with Outstanding As-Cast Specific Yield Strengths at Elevated Temperatures, Scr. Mater., 2021, 204, p 114132.

M.L. Wang, Y.P. Lu, and G.J. Zhang, A Novel High-Entropy Alloy Composite Coating with Core-Shell Structures Prepared by Plasma Cladding, Vacuum, 2021, 184, p 109905.

Y.P. Lu, H.F. Huang, and X.Z. Gao, A promising New Class of Irradiation Tolerant Materials: Ti2ZrHfV0.5Mo0.2 High-Entropy Alloy, J. Mater. Sci. Technol., 2019, 35, p 369–373.

M.L. Wang, Y.P. Lu, and J.G. Lan, Lightweight, Ultrastrong and High Thermal-Stable Eutectic High-Entropy Alloys for Elevated-Temperature Applications, Acta Mater., 2023, 248, p 118806.

Y. Zhang, T.T. Zuo, and Z. Tang, Microstructures and Properties of High-Entropy Alloys, Prog. Mater. Sci., 2014, 61, p 1–93.

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448–511.

Z. Wu, C.M. Parish, and H. Bei, Nano-Twin Mediated Plasticity in Carbon-Containing FeNiCoCrMn High Entropy Alloys, J. Alloy. Compd., 2015, 647, p 815–822.

A.S. Tirunilai, J. Sas, K.P. Weiss, and A. Kauffmann, Peculiarities of Deformation of CoCrFeMnNi at Cryogenic Temperatures, J. Mater. Res., 2018, 33, p 3287.

J.M. Park, J. Moon, and J.W. Bae, Role of BCC Phase on Tensile Behavior of Dual-Phase Al0.5CoCrFeMnNi High-Entropy Alloy at Cryogenic Temperature, Mater. Sci. Eng. A, 2019, 746, p 443–447.

Z. Lei, X. Liu, and Y. Wu, Enhanced Strength and Ductility in a High-Entropy Alloy Via Ordered Oxygen Complexes, Nature, 2018, 563, p 546–550.

Y.H. Jo, W.M. Choi, and D.G. Kim, FCC to BCC Transformation-Induced Plasticity Based on Thermodynamic Phase Stability in Novel V10Cr10Fe45CoxNi35-x Medium-Entropy Alloys, Sci/ Rep., 2019, 9, p 2948.

Y.H. Jo, D.G. Kim, and M.C. Jo, Effects of Deformation-Induced BCC Martensitic Transformation and Twinning on Impact Toughness and Dynamic Tensile Response in Metastable VCrFeCoNi High-Entropy Alloy, J. Alloy. Compd., 2019, 785, p 1056–1067.

D. Wei, X. Li, and J. Jiang, Novel Co-Rich High Performance Twinning-Induced Plasticity (twip) and Transformation-Induced Plasticity (trip) High-Entropy Alloys, Scr. Mater., 2019, 165, p 39–43.

L. Guo, X.Q. Ou, and S. Ni, Effects of Carbon on the Microstructures and Mechanical Properties of FeCoCrNiMn High Entropy Alloys, Mater. Sci. Eng. A, 2019, 746, p 356–362.

Y. Han, H. Li, and H. Feng, Enhancing the Strength and Ductility of CoCrFeMnNi High-Entropy Alloy by Nitrogen Addition, Mater. Sci. Eng. A., 2020, 789, p 139587.

D.E. Jodi, J. Park, and N. Park, Strengthening of Ultrafine-Grained Equiatomic CoCrFeMnNi High-Entropy Alloy by Nitrogen Addition, Mater. Lett., 2019, 258, p 126772.

J.W. Simmons, Overview: High-Nitrogen Alloying of Stainless Steels, Mater. Sci. Eng. A, 1996, 207, p 159–169.

T. Tsuchiyama, S. Takaki, and H. Ito, Fabrication of Ultrahigh Nitrogen Austenitic Steels by Nitrogen Gas Absorption into Solid Solution, Metall. Mater. Trans. A, 2003, 34, p 2591–2599.

H.S. Wang, G. Yuan, and Y.X. Zhang, Microstructural Evolution and Mechanical Properties of Duplex TRIP Steel Produced by Strip Casting, Mater. Sci. Eng. A, 2017, 692, p 43–52.

H.S. Wang, G. Yuan, and J. Kang, Microstructural Evolution and Mechanical Properties of Dual Phase Steel Produced by Strip Casting, Mater. Sci. Eng. A., 2017, 703, p 486–495.

M.F. Lan, Y.X. Zhang, and F. Feng, Effect of Annealing after Strip Casting on Microstructure, Precipitates and Texture in Non-Oriented Silicon Steel Produced by Twin-Roll Strip Casting, Mater. Charact., 2018, 142, p 531–539.

H.S. Di, The Development and Prospects of Twin Roll Strip Casting Process, Hena Metal., 2005, 13, p 3–7.

M. Annasamy, N. Haghdadi, and A. Taylor, Static Recrystallization and Grain Growth Behaviour of Al0.3CoCrFeNi High Entropy Alloy, Mater. Sci. Eng. A, 2019, 754, p 282–294.

P. Asghari-Rad, P. Sathiyamoorthi, and J.W. Bae, Effect of Grain Size on the Tensile Behavior of V10Cr15Mn5Fe35Co10Ni25 High Entropy Alloy, Mater. Sci. Eng. A, 2019, 744, p 610–617.

J.X. Hou, X.H. Shi, and J.W. Qiao, Ultrafine-Grained Dual Phase Al04.5CoCrFeNi High-Entropy Alloys, Mater. Des., 2019, 180, p 107910.

B. Gwalani, S. Gorsse, and D. Choudhuri, Tensile Yield Strength of a Single Bulk Al0.3CoCrFeNi High Entropy alloy can be Tuned from 160 MPa to 1800 MPa, Scr. Mater., 2019, 162, p 18–23.

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, and C.T. Liu, Ductile CoCrFeNiMox High Entropy Alloys Strengthened by Hard Intermetallic Phases, Acta Mater., 2016, 116, p 332–3342.

Acknowledgments

This work was financially supported by the National MCF (Magnetic Confinement Fusion) Energy R&D Program of China (with Grant No. 2018YFE0306102).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ran, R., Zhang, Yx., Wang, Y. et al. Effect of Annealing Treatment on Precipitates and Tensile Properties of FeCoCrNiVN High-Entropy Alloy Produced by Twin-Roll Casting. J. of Materi Eng and Perform 33, 3374–3383 (2024). https://doi.org/10.1007/s11665-023-08239-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08239-z