Abstract

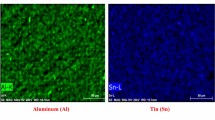

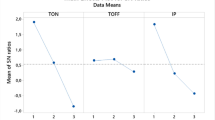

Wire electrical discharge machining (WEDM) has become the most important advanced production technology compared to other methods. The major goal of the current experiment is to use WEDM to ascertain the machining characteristics of the aluminum alloy EN AW-6082 T6, which has better corrosion resistance. The trials were planned using the design of experiments—response surface methodology. In total, 32 sWEDM experiments with molybdenum wire were conducted. The methods were used to reduce surface roughness (SR) and dimensional deviation (DD) by influencing machining parameters such as pulse on time (Ton), pulse off time (Toff), spark gap voltage (GV), peak current, and wire tension to help industrialists manufacture cost-effective industrial components. After machining, the significance of each parameter was determined using an analysis of variance (ANOVA), which revealed that for SR, Ton is the influencing factor and for DD, GV is the dominant factor. The measured output was optimized using desirability function analysis. The confirmatory tests were carried out, which indicate that the desired consistency with individual parameters was achieved, ensuring the validity of this investigation.

Similar content being viewed by others

References

D.J.D. James, L. Ganesh Babu, M. Ramesh, M. Ravichandran, D.J.D. James, L. Ganesh Babu, M. Ramesh, and M. Ravichandran, Mechanical and Tribological Characteristics of ZrO2 Reinforced Al2014 Matrix Composites Produced via Stir Casting Route, MRE, 2019, 6(11), p 115542.

M. Ramesh, D. Jafrey Daniel, and M. Ravichandran, Investigation on Mechanical Properties and Wear Behaviour of Titanium Diboride Reinforced Composites, FME Trans., 2019, 47(4), p 873–879.

G. Selvakumar, G. Sornalatha, S. Sarkar, and S. Mitra, Experimental Investigation and Multi-Objective Optimization of Wire Electrical Discharge Machining (WEDM) of 5083 Aluminum Alloy, Trans. Nonferrous Met. Soc. China, 2014, 24, p 373–379.

J.P. Davim, Nonconventional Machining, De Gruyter, 2022. https://doi.org/10.1515/9783110584479

K.G. Swift and J.D. Booker, Non-traditional Machining Processes, Manufacturing Process Selection Handbook. Elsevier, 2013, p 205–226

J.P. Davim, Computational Methods and Production Engineering: Research and Development, Woodhead Publishing, 2017.

J.P. Davim, Statistical and Computational Techniques in Manufacturing, Springer, 2012.

J.P. Davim and P. Aveiro, Design of Experiments in Production Engineering, Springer, 2016.

J.P. Davim and C.A.C. Antonio, Optimisation of Cutting Conditions in Machining of Aluminium Matrix Composites Using a Numerical and Experimental Model, J. Mater. Process. Technol., 2001, 112(1), p 78–82.

L. Li, X.T. Wei, and Z.Y. Li, Surface Integrity Evolution and Machining Efficiency Analysis of W-EDM of Nickel-Based Alloy, Appl. Surf. Sci., 2014, 313, p 138–143.

R. Chakravorty, S.K. Gauri, and S. Chakraborty, Optimization of Correlated Responses of EDM Process, Mater. Manuf. Process., 2012, 27, p 337–347.

S. Abdulkareem, A. Ali Khan, and M. Konneh, Cooling Effect on Electrode and Process Parameters in EDM, Mater. Manuf. Process., 2010, 25, p 462–466.

R. Soundararajan, A. Ramesh, N. Mohanraj, and N. Parthasarathi, An Investigation of Material Removal Rate and Surface Roughness of Squeeze Casted A413 Alloy on WEDM by Multi Response Optimization Using RSM, J. Alloys Compd., 2016, 685, p 533–545. https://doi.org/10.1016/j.jallcom.2016.05.292

G.K. Pandiyan, T. Prabaharan, D.J.D. James, N.T. Sivalingam, and Vinothkumar, Improvement on the Machinability Characteristics of AA6061-T6/15 Wt.% SiC Composites by Response Surface Methodology, Surf. Topogr. Metrol. Prop., 2021, 9(3), p 35050. https://doi.org/10.1088/2051-672X/ac2560

S. Habib, Optimization of Machining Parameters and Wire Vibration in Wire Electrical Discharge Machining Process, Mech. Adv. Mater. Mod. Process., 2017, 3(1), p 1–9.

P. Sivaprakasam, P. Hariharan, and S. Gowri, Optimization of Micro-WEDM Process of Aluminum Matrix Composite (A413-B4C): A Response Surface Approach, Mater. Manuf. Process., 2013, 28(12), p 1340–1347. https://doi.org/10.1080/10426914.2013.823502

D. Dwaipayan, N. Titas, and B. Asish, Parametric Study for Wire Cut Electrical Discharge Machining of Sintered Titanium, Strojnícky časopis J. Mech. Eng., 2019, 69(1), p 17–38. https://doi.org/10.2478/scjme-2019-0002

A. Goyal, Investigation of Material Removal Rate and Surface Roughness during Wire Electrical Discharge Machining (WEDM) of Inconel 625 Super Alloy by Cryogenic Treated Tool Electrode, J. King Saud Univ. Sci., 2017, 29(4), p 528–535. https://doi.org/10.1016/j.jksus.2017.06.005

P. Shandilya, P.K. Jain, and N.K. Jain, Parametric Optimization During Wire Electrical Discharge Machining Using Response Surface Methodology, Procedia Eng., 2012, 38, p 2371–2377. https://doi.org/10.1016/j.proeng.2012.06.283

P. Gupta, R. Khanna, R. Gupta, and N. Sharma, Effect of Process Parameters on Kerf Width in WEDM for HSLA Using Response Surface Methodology, J. Eng. Technol., 2012 https://doi.org/10.4103/0976-8580.94230

B. Choudhuri, R. Sen, S.K. Ghosh, and S.C. Saha, Modelling and Multi-Response Optimization of Wire Electric Discharge Machining Parameters Using Response Surface Methodology and Grey-Fuzzy Algorithm, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2015, 231(10), p 1760–1774. https://doi.org/10.1177/0954405415607382

N. Roy, A. Ghosh, P.P. Dey, and M. Ghosh, Parametric Optimization of WEDM for EN AW 7075 Alloy Processed by ECAP, Mater. Today Proc., 2020, 33, p 5279.

D. Kanagarajan, R. Karthikeyan, K. Palanikumar, and J.P. Davim, Optimization of Electrical Discharge Machining Characteristics of WC/Co Composites Using Non-Dominated Sorting Genetic Algorithm (NSGA-II), Int. J. Adv. Manuf. Technol., 2008, 36, p 1124–1132.

R. Magabe, N. Sharma, K. Gupta, and J. Paulo Davim, Modeling and Optimization of Wire-EDM Parameters for Machining of Ni 558 Ti Shape Memory Alloy Using Hybrid Approach of Taguchi and NSGA-II, Int. J. Adv. Manuf. Technol., 2019, 102, p 1703–1717.

K.P. Ganesan, J.D.J. Dhilip, V. Sivalingam, A. Duraipalam, G. Seenivasan, G.K. Perumal, B. Karthikeyan, R.K. Rajagopal, and M. Chandran, Machinability Analysis and Optimisation of EDM in AA6082/3 Wt% BN/1 Wt% MoS2 Hybrid Composites Using Entropy Method Weights Integrated with Complex Proportional Assessment (COPRAS) Method, Int. J. Adv. Manuf. Technol., 2022 https://doi.org/10.1007/s00170-022-10462-2

D. Jafrey Daniel James, N. Ganesh, and P.G. Karthik, Machinability Analysis and Optimization by the Taguchi-gra-pca Approach of PMEDM Process Parameters of Monel K 500, Functional Composite Materials: Manufacturing Technology and Experimental Application. BENTHAM SCIENCE PUBLISHERS, 2022, p 19–34

G. Karthik Pandiyan, T. Prabaharan, and D. Jafrey Daniel James, Optimization of Machining Process Parameters to Calculate Surface Finish, Metal Removal Rate, and Cutting Force on AA6061-T6, Functional Composite Materials: Manufacturing Technology and Experimental Application. BENTHAM SCIENCE PUBLISHERS, 2022, p 1–18

K.L. Meena, A. Manna, S.S. Banwait, and Jaswanti, Effect of Wire Feedrate and Wire Tension during Machinng of PR-Al-SiC-MMC’s by WEDM, Eur. J. Eng. Technol., 2013, 1(1), p 7–13.

A. Kumar, N. Grover, A. Manna, J.S. Chohan, R. Kumar, S. Singh, C. Prakash, and C.I. Pruncu, Investigating the Influence of Wedm Process Parameters in Machining of Hybrid Aluminum Composites, Adv. Compos. Lett., 2020, 29, p 1–14.

T. Chaudhary, A.N. Siddiquee, and A.K. Chanda, Effect of Wire Tension on Different Output Responses during Wire Electric Discharge Machining on AISI 304 Stainless Steel, Def. Technol., 2019, 15(4), p 541–544. https://doi.org/10.1016/j.dt.2018.11.003

U.A. Dabade and S.S. Karidkar, Analysis of Response Variables in WEDM of Inconel 718 Using Taguchi Technique, Procedia CIRP, 2016, 41, p 886–891. https://doi.org/10.1016/j.procir.2016.01.026

G.K. Pandiyan, T. Prabaharan, D.J.D. James, and V. Sivalingam, Machinability Analysis and Optimization of Electrical Discharge Machining in AA6061-T6/15wt.% SiC Composite by the Multi-Criteria Decision-Making Approach, J. Mater. Eng. Perform., 2021, 31, p 3741.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Srinivasan, D., Fakkir, M., Lenin, K. et al. Evaluation of Wire Electrical Discharge Machining Performance Features on EN AW-6082 T6 Aluminum Alloy and Optimization of Machining Characteristics. J. of Materi Eng and Perform 33, 3546–3558 (2024). https://doi.org/10.1007/s11665-023-08234-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08234-4