Abstract

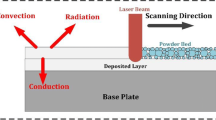

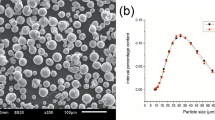

A three-dimensional numerical model of SLM BN/316L stainless steel composites was established by the Finite Volume Method (FVM), considering the Marangoni effect, recoil pressure, latent heat of evaporation and surface tension at the phase interface. SLM experiments were conducted to fabricate BN/316L stainless steel composites with different BN content and scanning speeds. In simulation, the effects of BN content and scanning speed on the temperature field and the morphology evolution of the molten pool of BN/316L stainless steel composites were investigated. In addition, the microstructure and mechanical properties of the samples were studied by experiments. The simulated results indicated that the mixed particles were melted with no balling or splashing on the surface of 1wt.% BN/316L stainless steel composite. When the BN particles increased to 2wt.%, balling and splashing became obvious, accompanied by a large bulge on the uneven melt track, due to the alteration in surface tension of the melt caused by BN particles. Under the combined action of recoil pressure and surface tension, the liquid at the top of the keyhole received an upward force, which contributed to the formation of splash. Besides, the addition of BN particles promoted the heat transfer of molten pool which was beneficial to the energy absorption of the powder bed. The peak temperature, heating rate, and cooling rate in the molten pool tended to increase with increasing BN particles. The simulated molten pool containing 2wt.% BN was deeper and narrower than that containing 1wt.% BN. As the scanning speed decreased, the peak temperature of the molten pool increased. The sample at the scanning speed of 525 mm/s had the highest relative density. Compared with 316L stainless steel, the composite with 1wt.% BN showed higher microhardness and relative density, as well as better wear resistance, which was attributed to grain refinement.

Similar content being viewed by others

Date Availability

The data used to support the founding of this study are available from the corresponding author upon request.

References

T.J.A. Doel, M.H. Loretto, and P. Bowen, Mechanical Properties of Aluminium-Based Particulate Metal-Matrix Composites, Composites, 1993, 24, p 270–275.

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia, Particulate Reinforced Metal Matrix Composites—a Review, JMatS, 1991, 26, p 1137–1156.

W.H. Yu, S.L. Sing, C.K. Chua, C.N. Kuo, and X.L. Tian, Particle-Reinforced Metal Matrix Nanocomposites Fabricated by Selective Laser Melting: A State of the Art Review, PrMS, 2019, 104, p 330–379.

E. Pagounis and V.K. Lindroos, Processing and Properties of Particulate Reinforced Steel Matrix Composites, Mater. Sci. Eng. A, 1998, 246, p 221–234.

W.G. Zhai, W. Zhou, and S.M.L. Nai, In-situ Formation of TiC Nanoparticles in Selective Laser Melting of 316L with Addition of Micronsized TiC Particles, Mater. Sci. Eng. Struct., 2022, 829, p 142179.

B. AlMangour, Y.-K. Kim, D. Grzesiak, and K.-A. Lee, Novel TiB2-Reinforced 316L Stainless Steel Nanocomposites with Excellent Room- and High-Temperature Yield Strength Developed by Additive Manufacturing, Compos. B Eng., 2019, 156, p 51–63.

B. AlMangour, D. Grzesiak, and J.-M. Yang, Rapid Fabrication of Bulk-Form TiB2/316L Stainless Steel Nanocomposites with Novel Reinforcement Architecture and Improved Performance by Selective Laser Melting, J. Alloys Compd., 2016, 680, p 480–493.

W. Zhai, Z. Zhu, W. Zhou, S.M.L. Nai, and J. Wei, Selective Laser Melting of Dispersed TiC Particles Strengthened 316L Stainless Steel, Compos. Part B Eng., 2020, 199, p 108291.

B. AlMangour, M.-S. Baek, D. Grzesiak, and K.-A. Lee, Strengthening of Stainless Steel by Titanium Carbide Addition and Grain Refinement during Selective Laser Melting, Mater. Sci. Eng. A, 2018, 712, p 812–818.

M. Schmidt, M. Merklein, D. Bourell, D. Dimitrov, T. Hausotte, K. Wegener, L. Overmeyer, F. Vollertsen, and G.N. Levy, Laser Based Additive Manufacturing in Industry and Academia, CIRP Ann., 2017, 66, p 561–583.

D. Gu, X. Shi, R. Poprawe, D.L. Bourell, R. Setchi, and J. Zhu, Material-Structure-Performance Integrated Laser-Metal Additive Manufacturing, Science, 2021, 372, p 6545.

J. Li, C. Duan, M. Zhao, and X. Luo, A Review of Metal Additive Manufacturing Application and Numerical Simulation, IOP Conf. Ser. Earth Environ. Sci., 2019, 252, p 022036.

P.P. Yuan and D.D. Gu, Molten Pool Behaviour and its Physical Mechanism during Selective Laser Melting of TiC/AlSi10Mg Nanocomposites: Simulation and Experiments, J Phys. D Appl. Phys., 2015, 48, p 035303.

J. Wu and L. Wang, Selective Laser Melting Manufactured CNTs/AZ31B Composites: Heat Transfer and Vaporized Porosity Evolution, JMatR, 2018, 33, p 2752–2762.

S.M.S. Murshed, K.C. Leong, and C. Yang, A Model for Predicting the Effective Thermal Conductivity of Nanoparticle-Fluid Suspensions, IJN, 2011, 05, p 23–33.

M. Xia, D. Gu, G. Yu, D. Dai, H. Chen, and Q. Shi, Porosity Evolution and its Thermodynamic Mechanism of Randomly Packed Powder-Bed during Selective Laser Melting of Inconel 718 Alloy, Int. J. Mach. Tools Manuf, 2017, 116, p 96–106.

B. AlMangour, D. Grzesiak, J. Cheng, and Y. Ertas, Thermal Behavior of the Molten Pool, Microstructural Evolution, and Tribological Performance during Selective Laser Melting of TiC/316L Stainless Steel Nanocomposites: Experimental and Simulation Methods, J. Mater. Process. Technol., 2018, 257, p 288–301.

D. Gu, C. Ma, M. Xia, D. Dai, and Q. Shi, A Multiscale Understanding of the Thermodynamic and Kinetic Mechanisms of Laser Additive Manufacturing, Engineering, 2017, 3, p 675–684.

Standard Test Methods for Determining Average Grain Size, ASTM E112-13, ASTM Internatinal, 2021, p 1–28

L. Cao, Workpiece-Scale Numerical Simulations of SLM Molten Pool Dynamic Behavior of 316L Stainless Steel, Comput. Math. Appl., 2021, 96, p 209–228.

L. Cao, D. Liao, Y. Lu, and T. Chen, Heat Transfer Model of Directional Solidification by LMC Process for Superalloy Casting Based on Finite Element Method, MMTA, 2016, 47, p 4640–4647.

J.-H. Cho, D.F. Farson, J.O. Milewski, and K.J. Hollis, Weld Pool Flows during Initial Stages of Keyhole Formation in Laser Welding, J. Phys. D Appl. Phys., 2009, 42, p 175502.

C. Panwisawas, C. Qiu, M.J. Anderson, Y. Sovani, R.P. Turner, M.M. Attallah, J.W. Brooks, and H.C. Basoalto, Mesoscale Modelling of Selective Laser Melting: Thermal Fluid Dynamics and Microstructural Evolution, Comput. Mater. Sci., 2017, 126, p 479–490.

S.A. Khairallah, A.T. Anderson, A. Rubenchik, and W.E. King, Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter, and Denudation Zones, AcMat, 2016, 108, p 36–45.

Z.H. Li, S. Yang, B. Liu, W.P. Liu, Z.Z. Kuai, and Y.F. Nie, Simulation of Temperature Field and Stress Field of Selective Laser Melting of Multi-Layer Metal Powder, Opt. Laser Technol., 2021, 140, p 106782.

M. Alimardani, E. Toyserkani, and J.P. Huissoon, A 3D Dynamic Numerical Approach for Temperature and Thermal Stress Distributions in Multilayer Laser Solid Freeform Fabrication Process, OptLE, 2007, 45, p 1115–1130.

Y.F. Tian, L.J. Yang, D.J. Zhao, Y.M. Huang, and J.J. Pan, Numerical Analysis of Powder Bed Generation and Single Track Forming for Selective Laser Melting of SS316L Stainless Steel, J. Manuf. Process., 2020, 58, p 964–974.

Y.C. Wu, C.H. San, C.H. Chang, H.J. Lin, R. Marwan, S. Baba, and W.S. Hwang, Numerical Modeling of Melt-Pool Behavior in Selective Laser Melting with Random Powder Distribution and Experimental Validation, J. Mater. Process. Technol., 2018, 254, p 72–78.

P. Bidare, I. Bitharas, R.M. Ward, M.M. Attallah, and A.J. Moore, Fluid and Particle Dynamics in Laser Powder Bed Fusion, AcMat, 2018, 142, p 107–120.

M.H. Dao and J. Lou, Simulations of Laser Assisted Additive Manufacturing by Smoothed Particle Hydrodynamics, CMAME, 2021, 373, p 113491.

D. Gu and P. Yuan, Thermal Evolution Behavior and Fluid Dynamics during Laser Additive Manufacturing of Al-Based Nanocomposites: Underlying Role of Reinforcement Weight Fraction, JAP, 2015, 118, p 233109.

C. Körner, E. Attar, and P. Heinl, Mesoscopic Simulation of Selective Beam Melting Processes, J. Mater. Process. Technol., 2011, 211, p 978–987.

B.J.M. Freitas, V.A. de Oliveira, P. Gargarella, G.Y. Koga, and C. Bolfarini, Microstructural Characterization and Wear Resistance of Boride-Reinforced Steel Coatings Produced by Selective Laser Melting (SLM), SuCT, 2021, 426, p 127779.

S. Mahathanabodee, T. Palathai, S. Raadnui, R. Tongsri, and N. Sombatsompop, Effects of Hexagonal Boron Nitride and Sintering Temperature on Mechanical and Tribological Properties of SS316L/h-BN Composites, Mater. Des., 2013, 46, p 588–597.

D. Uzunsoy, Investigation of Dry Sliding Wear Properties of Boron Doped Powder Metallurgy 316L Stainless Steel, Mater. Des., 2010, 31, p 3896–3900.

B. AlMangour, D. Grzesiak, T. Borkar, and J.-M. Yang, Densification Behavior, Microstructural Evolution, and Mechanical Properties of TiC/316L Stainless Steel Nanocomposites Fabricated by Selective Laser Melting, Mater. Des., 2018, 138, p 119–128.

Acknowledgments

This research was supported by the Fundamental Research Funds for the Central Universities (2022YJSJD07).

Author information

Authors and Affiliations

Contributions

LL contributed to conceptualization, investigation, data curation, writing—original draft, and writing—review & editing. TL contributed to conceptualization, methodology, formal analysis, investigation, writing—original draft, and writing—review & editing. XD contributed to data curation, resources, and writing—review & editing. MH contributed to data curation, investigation, writing—original draft, and writing—review & editing. FC contributed to software, methodology, resources, and writing—original draft. MQ contributed to conceptualization, methodology, supervision, and resources.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, L., Liu, T., Dong, X. et al. Numerical Simulation of Thermal Dynamic Behavior and Morphology Evolution of the Molten Pool of Selective Laser Melting BN/316L Stainless Steel Composite. J. of Materi Eng and Perform 33, 2968–2990 (2024). https://doi.org/10.1007/s11665-023-08210-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08210-y