Abstract

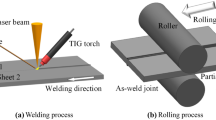

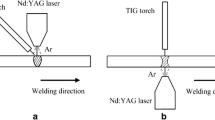

This paper adopted the new process of double-sided oscillation laser autogenous backing welding and double-sided oscillation laser–TIG hybrid filling welding to achieve 80 mm thick SA-738Gr.B steel narrow gap welding in the horizontal position. The microstructure, mechanical properties, and residual stress of the welded joints in the as-welded (AW) state and in the post-weld heat treatment (PWHT) state were analyzed comparatively. The results show that because of the high-temperature tempering effect of PWHT, the microstructure of the welded joint is transformed into a high-temperature tempered microstructure with the increase in alloy carbide precipitation. The grains growth of the backing weld and the base material is obvious. The relative frequency of the high-angle grain boundary of the weld increases. Under the PWHT, the tensile strength of the welded joint decreases, and the residual stresses of the welded joint are redistributed and reduced significantly.

Similar content being viewed by others

References

Y. Zhang, H. Hui, J. Zhang, Z. Zhou, X. Hu, and X. Cong, Prediction of Fracture Toughness of SA738Gr.B Steel in the Ductile-Brittle Transition Using Master Curve Method and Bimodal Master Curve Method, Int. J. Press. Vessel. Pip., 2020, 182, p 104033. https://doi.org/10.1016/j.ijpvp.2019.104033

J. Zhang, D. Cong, Y. Gu, and Y. Yu, Mechanical Properties of Welded Joint of SA 738 Gr.B, Electri. Weld. Mach., 2018, 48(09), p 26–31. https://doi.org/10.7512/j.issn.1001-2303.2018.09.05. (in Chinese)

Y. Ma, G. Ran, N. Chen, P. Lei, and Q. Shen, Investigation of Mechanical Properties and Proton Irradiation Behaviors of SA-738 Gr.B Steel Used as Reactor Containment, Nucl. Mater. Energy, 2016, 8, p 18–22. https://doi.org/10.1016/j.nme.2016.07.010

H.B. Liu, H.Q. Zhang, and J.F. Li, Toughness of SA738Gr.B steel Used for Nuclear Containment Vessel, Int. J. Press. Vessel. Pip., 2018, 168, p 200–209. https://doi.org/10.1016/j.ijpvp.2018.10.017

L.Z. Ding, Y. Lei, J. Zhang, and Q.S. Meng, An Investigation into the Weldability of SA-738Gr.B Steel, Mater. Res. Innovations, 2015, 19(sup5), p 1197–1201. https://doi.org/10.1179/1432891714Z.0000000001277

L. Ding, Researches on weldability and welding procedure for containment vessel and its accessories for AP1000 nuclear power [dissertation]. Taiyuan University of Technology, 2015. (in Chinese)

M. Jiang, W. Tao, Y. Chen, and F. Li, Comparison of Processing Window in Full Penetration Laser Welding of Thick High-Strength Steel Under Atmosphere and Sub-Atmosphere, Opt. Laser Technol., 2019, 109, p 449–455. https://doi.org/10.1016/j.optlastec.2018.08.023

J. Long, L.-J. Zhang, M.-X. Zhuang, L.-A. Bai, and S.-J. Na, Narrow-Gap Laser Welding with Beam Wobbling and Filler Wire and Microstructural Performance of Joints of Thick TC4 Titanium Alloy Plates, Opt. Laser Technol., 2022, 152, p 108089. https://doi.org/10.1016/j.optlastec.2022.108089

J. Shen, R. Gonçalves, Y.T. Choi, J.G. Lopes, J. Yang, N. Schell, H.S. Kim, and J.P. Oliveira, Microstructure and Mechanical Properties of Gas Metal Arc Welded CoCrFeMnNi Joints Using a 308 Stainless Steel Filler Metal, Scr. Mater., 2023, 222, p 115053. https://doi.org/10.1016/j.scriptamat.2022.115053

J. Shen, P. Agrawal, T.A. Rodrigues, J.G. Lopes, N. Schell, Z. Zeng, R.S. Mishra, and J.P. Oliveira, Gas Tungsten Arc Welding of As-cast AlCoCrFeNi2.1 Eutectic High Entropy Alloy, Mater Des, 2022, 223, p 111176. https://doi.org/10.1016/j.matdes.2022.111176

J.P. Oliveira, A. Shamsolhodaei, J. Shen, J.G. Lopes, R.M. Gonçalves, F.M. de Brito, L. Piçarra, Z. Zeng, N. Schell, N. Zhou, and K.H. Seop, Improving the Ductility in Laser Welded Joints of CoCrFeMnNi High Entropy Alloy to 316 Stainless Steel, Mater. Des., 2022, 219, p 110717. https://doi.org/10.1016/j.matdes.2022.110717

J.P. Oliveira, N. Schell, N. Zhou, L. Wood, and O. Benafan, Laser Welding of Precipitation Strengthened Ni-rich NiTiHf High Temperature Shape Memory Alloys: Microstructure and Mechanical Properties, Mater. Des., 2019, 162, p 229–234. https://doi.org/10.1016/j.matdes.2018.11.053

L. Wang, M. Gao, C. Zhang, and X. Zeng, Effect of Beam Oscillating Pattern on Weld Characterization of Laser Welding of AA6061-T6 Aluminum Alloy, Mater Des, 2016, 108, p 707–717. https://doi.org/10.1016/j.matdes.2016.07.053

F. Fetzer, M. Sommer, R. Weber, J.-P. Weberpals, and T. Graf, Reduction of Pores by Means of Laser Beam Oscillation During Remote Welding of AlMgSi, Opt. Laser Eng., 2018, 108, p 68–77. https://doi.org/10.1016/j.optlaseng.2018.04.012

V. Schultz, T. Seefeld, and F. Vollertsen, Gap Bridging Ability in Laser Beam Welding of Thin Aluminum Sheets, Phys. Procedia., 2014, 56, p 545–553. https://doi.org/10.1016/j.phpro.2014.08.037

C. Chen, W. Wang, D. Li, Y. Cai, Y. Zhang, and K. Zhang, Effect of Beam Oscillation on Microstructure and Properties of Laser-TIG Hybrid Welding of D406A Ultra-High Strength Steel, J. Manuf. Process., 2020, 57, p 798–805. https://doi.org/10.1016/j.jmapro.2020.07.048

A. Mahrle and E. Beyer, Hybrid Laser Beam Welding—Classification, Characteristics, and Applications, J. Laser Appl., 2006, 18(3), p 169–180. https://doi.org/10.2351/1.2227012

B. Hu and G. den Ouden, Synergetic Effects of Hybrid laser/arc Welding, Sci. Technol. Weld. Joining., 2013, 10(4), p 427–431. https://doi.org/10.1179/174329305X44170

B. Acherjee, Hybrid Laser Arc Welding: State-of-Art Review, Opt. Laser Technol., 2018, 99, p 60–71. https://doi.org/10.1016/j.optlastec.2017.09.038

S.D. Banik, S. Kumar, P.K. Singh, S. Bhattacharya, and M.M. Mahapatra, Prediction of Distortions and Residual Stresses in Narrow Gap Weld Joints Prepared by Hot Wire GTAW and its Validation with Experiments, Int. J. Press. Vessel. Pip., 2021, 193, p 104477. https://doi.org/10.1016/j.ijpvp.2021.104477

J. Huang, H. Chen, J. He, S. Yu, and D. Fan, Narrow Gap Applications of Swing TIG-MIG Hybrid Weldings, J. Mater. Process. Technol., 2019, 271, p 609–614. https://doi.org/10.1016/j.jmatprotec.2019.04.043

Z. Tian, Z. Qu and Z. Du, Grain Growth and Microstructure Transformation in Heat Affected Zone of Fine-Grain Steels, Mater. Sci. Technol., 2000, 03, p 16–20. https://doi.org/10.3969/j.issn.1005-0299.2000.03.004

Z. Jiang, Effects of High-Temperature Tempering on Mechanical Properties and Microstructure of SA738 Gr.B Steel, Metals, 2020, 10, p 1207. https://doi.org/10.3390/met10091207

Z. Jiang, X. Chen, H. Li, Z. Lei, Y. Chen, S. Wu, and Y. Wang, Grain Refinement and Laser Energy Distribution During Laser Oscillating Welding of Invar Alloy, Mater. Des., 2020, 186, p 108195. https://doi.org/10.1016/j.matdes.2019.108195

J. Zhang, S. Liu and Y. Gu, Effect of PWHT on Impact Property and Fracture Toughness of SA 738 Gr.B Steel Heat Affected Zone, Press. Vessel Technol., 2021, 38(08), p 29–33. https://doi.org/10.3969/j.issn.1001-4837.2021.08.005. ((in Chinese))

C. Zurbuchen, H.-W. Viehrig and F.-P. Weiss, Master Curve and Unified Curve Applicability to Highly Neutron Irradiated Western Type Reactor Pressure Vessel Steels, Nucl. Eng. Des., 2009, 239(7), p 1246–1253. https://doi.org/10.1016/j.nucengdes.2009.03.008

K. Wallin, Structural Integrity Assessment Aspects of the Master Curve methodology, Eng. Fract. Mech., 2010, 77(2), p 285–292. https://doi.org/10.1016/j.engfracmech.2009.02.010

X.Z. Zhang and J.F. Knott, Cleavage Fracture in Bainitic and Martensitic Microstructures, Acta Mater., 1999, 47(12), p 3483–3495. https://doi.org/10.1016/S1359-6454(99)00200-1

M. Zrilic, V. Grabulov, Z. Burzic, M. Arsic, and S. Sedmak, Static and Impact Crack Properties of a High-Strength Steel Welded Joint, Int. J. Press. Vessel Pip., 2007, 84(3), p 139–150. https://doi.org/10.1016/j.ijpvp.2006.09.021

X.D. Zuo, W. Zhang, J.P. Olineira, Y. Li, Z. Zeng, Z. Luo, and S.S. Ao, Wire-based Directed Energy Deposition of NiTiTa Shape Memory Alloys: Microstructure, Phase Transformation, Electrochemistry, X-ray Visibility and Mechanical Properties, Addit. Manuf., 2022, 59, p 103115. https://doi.org/10.1016/j.addma.2022.103115

C. Zhao, Z. Wang, D. Li, L. Kollo, Z. Luo, W. Zhang, and K.G. Prashanth, Selective Laser Melting of Cu–Ni–Sn: A Comprehensive Study on the Microstructure, Mechanical Properties, and Deformation Behavior, Int. J. Plast., 2021, 138, p 102926. https://doi.org/10.1016/j.ijplas.2021.102926

A. Kundu and D.P. Field, Influence of Plastic Deformation Heterogeneity on Development of Geometrically Necessary dislocation density in dual phase steel, Mater. Sci. Eng, A, 2016, 667, p 435–443. https://doi.org/10.1016/j.msea.2016.05.022

D. Wang, K. Zheng, C. Deng, B. Gong, S. Wu, and N. Xiao, Effects of PWHT on the Impact Toughness and Fracture Toughness of the Weld Metal Under Restraint Welding, Trans. China Weld. Inst., 2020, 41(08), p 63–67. https://doi.org/10.12073/j.hjxb.20190914001

S. Cui, Y. Shi, K. Sun, and S. Gu, Microstructure Evolution and Mechanical Properties of Keyhole Deep Penetration TIG Welds of S32101 Duplex Stainless Steel, Mater. Sci. Eng, A, 2018, 709, p 214–222. https://doi.org/10.1016/j.msea.2017.10.051

Y. Wang, D. Sun, C. Wang, G. Li, and D. Wu, Effect of Simulated Post- Welded Heat Treatment on Microstructure and Impact Properties of SA-738Gr B Steel Plate, Press. Vessel Technol., 2014, 31(01), p 10–14. https://doi.org/10.3969/j.issn.1001-4837.2014.01.002

B. Yu, P. Wang, X. Song, and S. Huo, The Residual Stress Relief of Post Weld Heat Treatment in SMA490BW Welded Joints: Simulation and Experiment, Int. J. Press. Vessel. Pip., 2022, 200, p 104852. https://doi.org/10.1016/j.ijpvp.2022.104852

Z. Zhang, P. Ge and G.Z. Zhao, Numerical Studies of Post Weld Heat Treatment on Residual Stresses in Welded Impeller, Int. J. Press. Vessel. Pip., 2017, 153, p 1–14. https://doi.org/10.1016/j.ijpvp.2017.05.005

Q. Jin, W. Jiang, W. Gu, J. Wang, G. Li, X. Pan, M. Song, K. Zhang, A. Wu, and S.-T. Tu, A Primary Plus Secondary Local PWHT Method for Mitigating Weld Residual Stresses in Pressure Vessels, Int. J. Press. Vessel Pip., 2021, 192, p 104431. https://doi.org/10.1016/j.ijpvp.2021.104431

Acknowledgments

Thanks to the Liao Ning Revitalization Talents Program (No. XLYC190203), National Key R and D Program of China (No.2018YFB1107900), National Natural Science Foundation of China (Nos. U1933129 and U21B2079), Key Program of the Natural Science Foundation of Tianjin (No.19JCZDJC39000 and 22YFFCYS00090), and the Open Research Fund of State Key Laboratory of High-Performance Complex Manufacturing, Central South University (Kfkt2021-13).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, M., Luo, Z. & Ao, S. Effects of Heat Treatment on Microstructure, Mechanical Properties, and Residual Stress of Oscillation Laser–Tungsten Inert Gas Hybrid Welded Joints for SA-738Gr.B Steel. J. of Materi Eng and Perform 33, 2694–2710 (2024). https://doi.org/10.1007/s11665-023-08202-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08202-y