Abstract

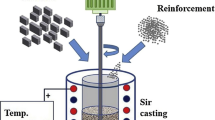

This study evaluated the high-cycle fatigue strength of AZ91D alloy and AZ91D-5SiC-1Gr (wt.%) hybrid magnesium composite. The samples were produced through the stir casting process, and properties were studied in as-cast and T6 aging heat-treated conditions. Microstructural characterizations, density, porosity, tensile properties, and high-cycle fatigue strength of produced alloy and hybrid composite were evaluated. The maximum obtained ultimate tensile strength, yield strength (0.2%), and ductility for T6-heat-treated hybrid composite were 176, 56.5 MPa, and 8.1%, respectively, and density of 1.855 g/cc. Stress-controlled, fully reversed high-cycle fatigue test was performed on the samples subjected to axial load and rotary bending load fatigue test. Fatigue results indicated that produced hybrid composite possessed higher cycle fatigue strength than the parent AZ91D alloy. AZ91D-5SiC-1Gr (wt.%) (T6) sample reported 55,434 cycles to failure at 28.25 MPa stress amplitude which is 4.33 times higher than as-cast AZ91D alloy. Maximum rotary bending load fatigue life of 101,916 cycles was obtained for T6-hybrid composite samples at 18.2 MPa stress amplitude. The reliability of fatigue strength has been studied through the R–S–N method, and results indicate that the fatigue life of the T6-hybrid composite possesses 81,377 cycles at 99% reliability and 98,627 cycles at 50% reliability. Hence, the addition of SiC and graphite and aging heat treatment at 100 °C enhances the tensile and fatigue strength of the parent AZ91D alloy.

Similar content being viewed by others

References

A.C. Serrenho, J.B. Norman, and J.M. Allwood, The Impact of Reducing Car Weight on Global Emissions: The Future Fleet in Great Britain, Philos. Trans. R. Soc. A Math. Phys. Eng. Sci., 2017, 375, p 201.

T.B. Abbott, Magnesium: Industrial and Research Developments Over the Last 15 Years, Corrosion, 2015, 71(2), p 120–127.

P. Emadi and C. Ravindran, The Influence of High Temperature Ultrasonic Processing Time on the Microstructure and Mechanical Properties AZ91E Magnesium Alloy, J. Mater. Eng. Perform., 2021, 30, p 1188–1199.

S.J. Huang, M. Subramani, A.N. Ali, D.B. Alemayehu, J.N. Aoh, and P.C. Lin, The Effect of Micro-SiCp Content on the Tensile and Fatigue Behavior of AZ61 Magnesium Alloy Matrix Composites, Int. J. Met., 2020, 15, p 780–793.

C. He, Y. Liu, J. Li, K. Yang, Q. Wang, and Q. Chen, Very-High-Cycle Fatigue Crack Initiation and Propagation Behaviours of Magnesium Alloy ZK60, Mater. Sci. Technol., 2018, 34(6), p 639–647.

C.R. Gagg and P.R. Lewis, In-service Fatigue Failure of Engineered Products and Structures—Case Study Review, Eng. Fail. Anal., 2009, 16(6), p 1775–1793.

S. Bagherifard et al., Effects of Nanofeatures Induced by Severe Shot Peening (SSP) on Mechanical, Corrosion and Cytocompatibility Properties of Magnesium alloy AZ31, Acta Biomater., 2018, 66, p 93–108.

K.U.K. Carsten Potzies, Fatigue of Magnesium Alloys, Adv. Eng. Mater., 2004, 6(5), p 281–289.

A.H. Jabbari, H. Delavar, and M. Sedighi, High Cycle Fatigue Behavior of Magnesium Matrix Nanocomposite at Elevated Temperatures, Mech. Mater, 2020, 142, p 103278.

Z. Li, A.A. Luo, Q. Wang, H. Zou, J. Dai, and L. Peng, Fatigue Characteristics of Sand-Cast AZ91D Magnesium Alloy, J. Magnes. Alloys, 2017, 5(1), p 1–12.

D. Yu, D. Zhang, Y. Luo, J. Sun, J. Xu, and F. Pan, Microstructure Evolution during High Cycle Fatigue in Mg-6Zn-1Mn Alloy, Mater. Sci. Eng. A, 2016, 658, p 99–108.

S. Wlodarski, D.Z. Avery, B.C. White, C.J.T. Mason, C. Cleek, M.B. Williams, P.G. Allison, and J.B. Jordon, Evaluation of Grain Refinement and Mechanical Properties of Additive Friction Stir Layer WELDING OF AZ31 MAGNESIUM ALLOY, J. Mater. Eng. Perform., 2021, 30, p 964–972.

N. Babacan, E. Yurtkuran, A. Balci, M. Bieda-Niemiec, and A. Jarzębska, Effects of Non-isothermal Aging on Microstructure and Mechanical Properties of WE43 Alloy, J. Mater. Eng. Perform., 2021, 30(11), p 7909–7916.

B.J. Wang, D.K. Xu, S.D. Wang, L.Y. Sheng, R.C. Zeng, and E.H. Han, Influence of solution treatment on the corrosion fatigue behavior of an as-forged Mg- Zn-Y-Zr alloy, Int. J. Fatigue, 2019, 120, p 46–55.

Z. Li, Q. Wang, A.A. Luo, J. Dai, H. Zou, and L. Peng, Effect of Heat Treatment on Strain– Controlled Fatigue Behavior of Cast Mg–Nd–Zn–Zr Alloy, J. Mater. Sci. Technol., 2018, 34(11), p 2091–2099.

M. Somasundaram and U. Narendra Kumar, Microstructural and Mechanical Properties of a Heat-Treated EV31A Magnesium Alloy Fabricated Using the Stir-Casting Process, Crystals, 2022, 2(8), p 1163.

X.Z. Wang, Y.Q. Wang, C.B. Ni, Y.X. Fang, X. Yu, and P. Zhang, The Effect of T4 and T6 Heat Treatments for Dynamic Impact Behavior of Casting Mg-Gd-Based Alloys, Vacuum, 2022, 205, p 111450.

D. Yu et al., High Cycle Fatigue Behavior of Extruded and Double-aged Mg-6Zn-1Mn Alloy, Mater. Sci. Eng. A, 2016, 662, p 1–8.

S.J. Huang and A.N. Ali, Effects of Heat Treatment on the Microstructure and Microplastic Deformation Behavior of SiC Particles Reinforced AZ61 Magnesium Metal Matrix Composite, Mater. Sci. Eng. A, 2018, 711(August), p 670–682.

X. Liu, S. Jia, and L. Nastac, Ultrasonic Cavitation-Assisted Molten Metal Processing of Cast a356-Nanocomposites, Int. J. Met., 2014, 8(3), p 51–57.

A.H. Jabbari and M. Sedighi, Investigation of Electromagnetic and Mechanical Stirring Sequence Effects on Production of Magnesium Matrix Nanocomposite, Int. J. Met., 2020, 14(2), p 489–504.

I. Aatthisugan, A. Razal Rose, and D. Selwyn Jebadurai, Mechanical and Wear Behaviour of AZ91D Magnesium Matrix Hybrid Composite Reinforced with Boron Carbide and Graphite, J. Magnes. Alloys, 2017, 5(1), p 20–25.

A. Packia Antony Amalan, N.M. Sivaram, C. Bavatharani, D. Ragupathy, A Study on the Effect of Ageing Heat Treatment on Hardness, Tensile and Corrosion Behaviour of Stir-Cast AZ91D-5SiC-1Gr Hybrid Magnesium Composite, Int. J. Met., 2021.

W.T. Huo, X. Lin, S. Yu, Z.T. Yu, W. Zhang, and Y.S. Zhang, Corrosion Behavior and Cytocompatibility of Nano-Grained AZ31 Mg Alloy, J. Mater. Sci., 2019, 54(5), p 4409–4422.

M.E. Turan, Y. Sun, F. Aydin, H. Zengin, Y. Turen, and H. Ahlatci, Effects of Carbonaceous Reinforcements on Microstructure and Corrosion Properties of Magnesium Matrix Composites, Mater. Chem. Phys., 2018, 218(July), p 182–188.

G. Wu, Y. Fan, H. Gao, C. Zhai, and Y.P. Zhu, The Effect of Ca and Rare Earth Elements on the Microstructure, Mechanical Properties and Corrosion Behavior of AZ91D, Mater. Sci. Eng. A, 2005, 408(1–2), p 255–263.

A.K.S. Bankoti, A.K. Mondal, S. Kumar, and B.C. Ray, Individual and Combined Additions of Calcium and Antimony on Microstructure and Mechanical Properties of Squeeze-Cast, Mater. Sci. Eng. A, 2015, 626, p 186–194.

P. Li, B. Tang, and E.G. Kandalova, Microstructure and Properties of AZ91D Alloy with Ca Additions, Mater. Lett., 2005, 59(6), p 671–675.

S. Bansal and J.S. Saini, Mechanical and Wear Properties of SiC/Graphite Reinforced Al359 Alloy-Based Metal Matrix Composite, Def. Sci. J., 2015, 65(4), p 330–338.

S. Aravindan, P.V. Rao, and K. Ponappa, Evaluation of Physical and Mechanical Properties of AZ91D/SiC Composites by Two Step Stir Casting Process, J. Magnes. Alloys, 2015, 3(1), p 52–62.

K. Soorya Prakash, P. Balasundar, S. Nagaraja, P.M. Gopal, and V. Kavimani, Mechanical and Wear Behaviour of Mg-SiC-Gr Hybrid Composites, J. Magnes. Alloys, 2016, 4(3), p 197–206.

J. Buha, Method of Heat Treating Magnesium Alloys, U.S. Pat., vol. US8,414,71, 2013.

H.L.A. Hassan, Effects of Particulate Volume Fraction on Cyclic Stress Response and Fatigue Life of AZ91D Magnesium Alloy Metal Matrix Composites, Mater. Sci. Eng. A, 2014, 600, p 188–194.

B. Stojanovic, M. Babic, S. Mitrovic, A. Vencl, N. Miloradovic, and M. Pantic, Tribological Characteristics of Aluminium Hybrid, J. Balk. Tribol. Assoc., 2013, 19(1), p 83–96.

L. Qi, L. Ju, J. Zhou, S. Li, T. Zhang, and W. Tian, Tensile and Fatigue Behavior of Carbon Fiber Reinforced Magnesium Composite Fabricated by Liquid–Solid Extrusion Following Vacuum Pressure Infiltration, J. Alloys Compd., 2017, 721, p 55–63.

M.F. Ashby and D.R.H. Jones, Engineering Materials 1, 4th ed. Elsevier, Amsterdam, 2012.

Y.W. Bao, Y.C. Zhou, X.X. Bu, and Y. Qiu, Evaluating Elastic Modulus and Strength of Hard Coatings by Relative Method, Mater. Sci. Eng. A, 2007, 458(1–2), p 268–274.

P. Ravindran, K. Manisekar, P. Narayanasamy, N. Selvakumar, and R. Narayanasamy, Application of Factorial Techniques to Study the Wear of Al Hybrid Composites with Graphite Addition, Mater. Des., 2012, 39, p 42–54.

S. Suresha and B.K. Sridhara, Wear Characteristics of Hybrid Aluminium Matrix Composites Reinforced with Graphite and Silicon Carbide Particulates, Compos. Sci. Technol., 2010, 70(11), p 1652–1659.

M. Preciado, P.M. Bravo, and D. Cardenas, Influence of Porosity in the Fatigue Behavior of the High-Pressure Die-Casting AZ91 Magnesium Alloys, J. Eng. Mater. Technol. Trans. ASME, 2016, 138(4), p 1–5.

H. Mayer, M. Papakyriacou, B. Zettl, and S.E. Stanzl-Tschegg, Influence of Porosity on the Fatigue Limit of Die Cast Magnesium and Aluminium Alloys, Int. J. Fatigue, 2003, 25(3), p 245–256.

S. Fintová and L. Kunz, Fatigue Properties of Magnesium Alloy AZ91 Processed by Severe Plastic Deformation, J. Mech. Behav. Biomed. Mater., 2015, 42, p 219–228.

Y.L. Xu, K. Zhang, L. Han, and M.F. Li, Analyses of P–S–N Curve and Fracture Morphology of Die-Casting Magnesium alloy AZ91D Containing Mischmetal, Appl. Mech. Mater., 2014, 467, p 103–107.

M.V. Achutha, B.K. Sridhara, and A. Budan, Fatigue Life Estimation of Hybrid Aluminium Matrix Composites, Int. J. Des. Manuf. Technol., 2008, 2(1), p 14–21.

H.J. Sutherland, P.S. Veers, The development of confidence limits for fatigue strength data, in ASME Wind Energy Symposium (2006), p. 63.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Packia Antony Amalan, A., Sivaram, N.M. & Subramanya, R. Influence of Silicon Carbide and Graphite Reinforcements and T6 Aging Heat Treatment on the Fatigue Characteristics of AZ91D Magnesium Alloy. J. of Materi Eng and Perform 33, 2751–2767 (2024). https://doi.org/10.1007/s11665-023-08154-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08154-3