Abstract

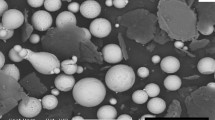

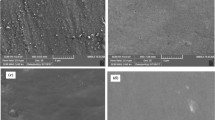

The Ni-Al intermetallic compounds coating was prepared on Q235 steel plate through plasma transferred arc (PTA) process using different powder system compositions. The compositions included high-purity Ni: Al, NiBSi: Al and NiCrBSi: Al, with a Ni: Al ratio of 3:1. The phase composition, microstructure, morphology, and corrosion resistance of the coatings were analyzed. The results indicated that the microstructure of the coatings changed to hypoeutectic with the addition of alloying elements in the powder system. The coatings prepared with high-purity Ni powder had low hardness and poor corrosion resistance due to the coarse dendrite structures of Ni-Al intermetallic compounds. The coatings produced with NiBSi powder contained lamellar eutectic structures and had good corrosion resistance and high hardness, as the Ni3Al phase grew in the NiAl phase. The coating fabricated with NiCrBSi powder showed a high density of chrysanthemum-like eutectic structures alternately formed by Ni3Al and α-Cr, and had refined grain size, good corrosion resistance, and high hardness.

Graphical Abstract

Similar content being viewed by others

References

M.A. Awotunde, O.O. Ayodele, A.O. Adegbenjo, A.M. Okoro, M.B. Shongwe, and P.A. Olubambi, Article NiAl Intermetallic Composites—a Review of Processing Methods, Reinforcements and Mechanical Properties, Int. J. Adv. Manuf. Technol., 2019, 104(5–8), p 1733–1747. https://doi.org/10.1007/s00170-019-03984-9s

O. Ozdemir, S. Zeytin, and C. Bindal, Article Tribological Properties of Ni3Al Produced by Pressure-Assisted Volume Combustion Synthesis, Tribol. Int., 2012, 53, p 22–27. https://doi.org/10.1016/j.triboint.2012.04.001s

J.T. Guo, L.Y. Sheng, Y. Xie, Z.X. Zhang, V.E. Ovcharenko, and H.Q. Ye, Article Microstructure and Mechanical Properties of Ni3Al and Ni3Al-1B Alloys Fabricated by SHS/HE, Intermetallics, 2011, 19(2), p 137–142. https://doi.org/10.1016/j.intermet.2010.08.027s

W. Liang, Y. Jiang, D. Hongxing, Y. He, N. Xu, J. Zou, B. Huang, and C.T. Liu, Article The Corrosion Behavior of Porous Ni3Al Intermetallic Materials in Strong Alkali Solution, Intermetallics, 2011, 19(11), p 1759–1765. https://doi.org/10.1016/j.intermet.2011.06.016s

S.R.A. Akhtar and V.K. Sikka, Article Cavitation Erosion Of NiAl, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 1999, 30(2), p 335–343.

J.T. Chang, C.H. Yeh, J.L. He, and K.C. Chen, Article Cavitation Erosion and Corrosion Behavior of Ni-Al Intermetallic Coatings, Wear, 2003, 255(1–6), p 162–169. https://doi.org/10.1016/s0043-1648(03)00199-6s

J. Wen, H. Cui, N. Wei, X. Song, G. Zhang, C. Wang, and Q. Song, Article Effect of Phase Composition and Microstructure on the Corrosion Resistance of Ni-Al Intermetallic Compounds, J. Alloys Compd., 2017, 695, p 2424–2433. https://doi.org/10.1016/j.jallcom.2016.11.138s

K.V. Rybalka, L.A. Beketaeva, N.G. Bukhan’ko, and A.D. Davydov, Article Electrochemical Behavior and the Rate of General Corrosion of NiAl Intermetallic Compound in the Unbuffered Sodium Chloride Solutions, Corros. Sci., 2011, 53(2), p 630–636. https://doi.org/10.1016/j.corsci.2010.10.016s

C. Xu, L. Du, B. Yang, and W. Zhang, Article The effect of Al Content on the Galvanic Corrosion Behaviour of Coupled Ni/Graphite and Ni-Al Coatings, Corros. Sci., 2011, 53(6), p 2066–2074. https://doi.org/10.1016/j.corsci.2011.02.019s

M. Alizadeh and G. Mohammadi, Article Effect of Micro-Alloying Chromium on the Corrosion Resistance of Nanocrystalline Nickel Aluminide Intermetallic Produced by Mechanical Alloying process, Mater. Lett., 2012, 67(1), p 148–150. https://doi.org/10.1016/j.matlet.2011.09.068s

H.L. Zhao, F. Qiu, S.B. Jin, and Q.C. Jiang, Article High Work-Hardening Effect of the Pure NiAl Intermetallic Compound Fabricated by the Combustion Synthesis and Hot Pressing Technique, Mater. Lett., 2011, 65(17–18), p 2604–2606. https://doi.org/10.1016/j.matlet.2011.05.091s

Y. Shu, A. Suzuki, N. Takata, and M. Kobashi, Article Fabrication of Porous NiAl Intermetallic Compounds with a Hierarchical Open-Cell Structure by Combustion Synthesis Reaction and Space Holder Method, J. Mater. Process. Technol., 2019, 264, p 182–189. https://doi.org/10.1016/j.jmatprotec.2018.09.010s

M. Abedi, A. Asadi, S. Sovizi, D. Moskovskikh, S. Vorotilo, and A. Mukasyan, Article Influence of Pulsed Direct Current on the Growth Rate of Intermetallic Phases in the Ni-Al System During Reactive Spark Plasma Sintering, Scr. Mater., 2022, 216, p 114759. https://doi.org/10.1016/j.scriptamat.2022.114759s

A. Pariyar, C.S. Perugu, K. Dash, and S.V. Kailas, Article Microstructure and Mechanical Behavior of High Toughness Al-Based Metal Matrix Composite Reinforced with In-situ Formed Nickel Aluminides, Mater. Charact., 2021, 171, p 110776. https://doi.org/10.1016/j.matchar.2020.110776s

X.Z. Jianjun Yuan and C. Zhang, Article NiAl intermetallic Coatings Prepared by Thermal Plasma Assisted Thermal Explosion Process, Optoelectron. Adv. Mater. Rapid Commun., 2015, 9(5), p 678–681.

Y. Yu, J. Zhou, J. Chen, H. Zhou, C. Guo, L. Wang, and L. Yang, Article Preparation, Microstructure and Tribological Behavior of Laser Cladding NiAl Intermetallic Compound coatings, Wear, 2012, 274–275, p 298–305. https://doi.org/10.1016/j.wear.2011.09.011s

A. Khajesarvi and G. Akbari, Article Properties Evaluation and Studying Production Mechanism of Nanocrystalline NiAl Intermetallic Compound by Mechanical Alloying, Metall. Mater. Trans. A, 2016, 47(4), p 1881–1888. https://doi.org/10.1007/s11661-016-3343-8s

M. Seyring and M. Rettenmayr, Article Impact of crystallography at Ni/NiAl Interfaces on the Nucleation of Ni3Al, Acta Mater., 2021, 208, p 116713. https://doi.org/10.1016/j.actamat.2021.116713s

L. Wang, C. Yao, J. Shen, Y. Zhang, T. Wang, H. Xu, L. Gao, and G. Zhang, Article Microstructures and Compressive Properties of NiAl-Cr(Mo) and NiAl-Cr Eutectic Alloys with Different Fe Contents, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2019, 744, p 593–603. https://doi.org/10.1016/j.msea.2018.12.085s

Y. Jianpeng, Y. Yueguang, and S. Jie, Article Cermet Composite Coating with a Ductile Ni3Al Binder Phase and an In-situ Cr7C3 Augmented Phase, Intermetallics, 2021, 138, p 107300. https://doi.org/10.1016/j.intermet.2021.107300s

B. Tang, D.A. Cogswell, G. Xu, S. Milenkovic, and Y. Cui, Article The Formation Mechanism of Eutectic Microstructures in NiAl-Cr Composites, Phys. Chem. Chem. Phys., 2016, 18(29), p 19773–19786. https://doi.org/10.1039/c6cp01921hs

F. Ji, S.-Y. Ma, T.-Z. Xin, and S.-Q. Wang, Article First-Principles Study of the Effect of Boron on Grain Boundary in NiAl, Comput. Mater. Sci., 2016, 121, p 1–5. https://doi.org/10.1016/j.commatsci.2016.04.024s

X.-L. Hu, X. Liu, Z. Xu, J. Liang, and T. Wang, Article First-Principles Investigation of the Effects of B Impurities on the Mechanical Properties of NiAl Intermetallics, Sci. China Phys. Mech. Astron., 2011, 54(5), p 809–814. https://doi.org/10.1007/s11433-011-4325-xs

Y. Wang, E. Hao, X. Zhao, Y. Xue, Y. An, and H. Zhou, Article Effect of Microstructure Evolution of Ti6Al4V Alloy on its Cavitation Erosion and Corrosion Resistance in Artificial Seawater, J. Mater. Sci. Technol., 2022, 100, p 169–181. https://doi.org/10.1016/j.jmst.2021.06.005s

M.E. Orazem, I. Frateur, B. Tribollet, V. Vivier, S. Marcelin, N. Pébère, A.L. Bunge, E.A. White, D.P. Riemer, and M. Musiani, Article Dielectric Properties of Materials Showing Constant-Phase-Element (CPE) Impedance Response, J. Electrochem. Soc., 2013, 160(6), p C215–C225. https://doi.org/10.1149/2.033306jess

Z. Cui, L. Wang, H. Ni, W. Hao, C. Man, S. Chen, X. Wang, Z. Liu, and X. Li, Article Influence of Temperature on the Electrochemical and Passivation Behavior of 2507 Super Duplex Stainless Steel in Simulated Desulfurized Flue Gas Condensates, Corros. Sci., 2017, 118, p 31–48. https://doi.org/10.1016/j.corsci.2017.01.016s

M.E.O. Bryan Hirschorn, B. Tribollet, V. Vivier, and I. Frateur, Article Constant-Phase-Element Behavior Caused by Resistivity Distributions in Films, J. Electrochem. Soc., 2010, 157(12), p 458–463. https://doi.org/10.1149/1.3499565s

H. Tian, Z. Cui, H. Ma, P. Zhao, M. Yan, X. Wang, and H. Cui, Article Corrosion Evolution and Stress Corrosion Cracking Behavior of a Low Carbon Bainite Steel in the Marine Environments: Effect of the Marine Zones, Corros. Sci., 2022, 206, p 110490. https://doi.org/10.1016/j.corsci.2022.110490s

H. Duan, B. Liu, A. Fu, J. He, T. Yang, C.T. Liu, and Y. Liu, Article Segregation Enabled Outstanding Combination of Mechanical and Corrosion Properties in a FeCrNi Medium Entropy alloy Manufactured by Selective Laser Melting, J. Mater. Sci. Technol., 2022, 99, p 207–214. https://doi.org/10.1016/j.jmst.2021.05.018s

J. Nie, L. Wei, Y. Jiang, Q. Li, and H. Luo, Article Corrosion Mechanism of Additively Manufactured 316 L Stainless Steel in 3.5 wt.% NaCl Solution, Mater. Today Commun., 2021, 26, p 101648. https://doi.org/10.1016/j.mtcomm.2020.101648s

E. Saebnoori, T. Shahrabi, H. Jafarian, and M. Ghaffari, Article Changes in the Resistance to Corrosion of Thermally Passivated Titanium Aluminide During Exposure to Sodium Chloride Solution, Res. Chem. Intermed., 2013, 41(2), p 1079–1095. https://doi.org/10.1007/s11164-013-1255-4s

L. Wang, J. Liang, H. Li, L. Cheng, and Z. Cui, Article Quantitative Study of the Corrosion Evolution and Stress Corrosion Cracking of high Strength Aluminum Alloys in Solution and Thin Electrolyte Layer Containing Cl, Corros. Sci., 2021, 178, p 109076. https://doi.org/10.1016/j.corsci.2020.109076s

B.K. Szczygieł, Małgorzata, Article Composite Ni/Al2O3 Coatings and their Corrosion Resistance, Electrochim. Acta, 2005, 50(20), p 4188–4195. https://doi.org/10.1016/j.electacta.2005.01.040s

L.W. Yuantao Zhao, Z. Qin, and C. Wang, Article The Roles of Ti Particles in Improving the Corrosion Resistance of Electrochemically Assembled Ni-Ti Composite Coatings, Corros. Sci., 2017, 73(9), p 1107–1118.

L. Wang, J. Zhang, Y. Gao, Q. Xue, L. Hu, and T. Xu, Article Grain Size Effect in Corrosion Behavior of Electrodeposited Nanocrystalline Ni Coatings in Alkaline Solution, Scr. Mater., 2006, 55(7), p 657–660. https://doi.org/10.1016/j.scriptamat.2006.04.009s

Y. Zhao, S. Xing, L. Wang, Y. Sun, H. Liu, K. Zhan, C. Jiang, V. Ji, and W. Li, Article Roles of Growth Mechanisms of Ni Deposits on Corrosion Behaviors of NixAlyTi Composite Coatings, Appl. Surf. Sci., 2019, 492, p 177–188. https://doi.org/10.1016/j.apsusc.2019.06.188s

S. Chen, H. Deng, G. Liu, and D. Zhang, Article Corrosion of Q235 Carbon Steel in Seawater Containing Mariprofundus Ferrooxydans and Thalassospira sp, Front. Microbiol., 2019, 10, p 936. https://doi.org/10.3389/fmicb.2019.00936s

D. Chaliampalias, S. Andronis, N. Pliatsikas, E. Pavlidou, D. Tsipas, S. Skolianos, K. Chrissafis, G. Stergioudis, P. Patsalas, and G. Vourlias, Article Formation and Oxidation Resistance of Al/Ni Coatings on Low Carbon Steel by Flame Spray, Surf. Coat. Technol., 2014, 255, p 62–68. https://doi.org/10.1016/j.surfcoat.2013.12.057s

M. Palcut, P. Priputen, M. Kusý, and J. Janovec, Article Corrosion Behaviour of Al-29at%Co Alloy in Aqueous NaCl, Corros. Sci., 2013, 75, p 461–466. https://doi.org/10.1016/j.corsci.2013.06.031s

V.M.C.A. Oliveira, C. Aguiar, A.M. Vazquez, A. Robin, and M.J.R. Barboza, Article Improving Corrosion Resistance of Ti-6Al-4V Alloy Through Plasma-Assisted PVD Deposited Nitride Coatings, Corros. Sci., 2014, 88, p 317–327. https://doi.org/10.1016/j.corsci.2014.07.047s

Acknowledgments

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Funding

The authors did not receive support from any organization for the submitted work. The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Contributions

Conceptualization: LC, ML, SW; Methodology: SW, ZG, BL; Formal analysis and investigation: JX, ZD, ZG; Writing-original draft preparation: LC; Writing-review and editing: ML, SW, BL.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, L., Li, M., Wang, S. et al. Microstructure and Corrosion Resistance of Ni-Al Coating Prepared by Plasma Transferred Arc Technology. J. of Materi Eng and Perform 33, 1596–1614 (2024). https://doi.org/10.1007/s11665-023-08084-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08084-0