Abstract

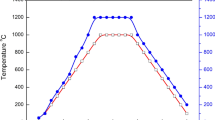

In this work, the phase transformation, microstructure, and mechanical properties of medium manganese steels containing 1.0 and 2.5% aluminum (mass%) were investigated at different intercritical annealing (IA) temperatures (670-820 °C) after very short IA times (1 min) using thermodynamic simulations, scanning electron microscopy, transmission electron microscopy, x-ray diffraction and uniaxial tensile tests. The results show that with the addition of aluminum, the temperature range between A1 and A3 increases from 338 °C for 1.0% Al to 506 °C for 2.5% Al. The retained austenite (RA) has two different morphologies, namely polygonal and lath. Most of the RA transformed into martensite during deformation. Two types of martensite were observed: the α’-martensite and ε-martensite. The steel with 2.5% aluminum (mass%), after IA at 790 °C, shows the best combination of tensile properties, including a tensile strength of 982.5 MPa, an elongation of 42.96%, and tensile strength × total elongation greater than 42 GPa%.

Similar content being viewed by others

References

J. Zhao and Z. Jiang, Thermomechanical Processing of Advanced High Strength Steels, Prog. Mater. Sci. Elsevier Ltd, 2018, 94, p 174–242. https://doi.org/10.1016/j.pmatsci.2018.01.006

Y.K. Lee and J. Han, Current Opinion in Medium Manganese Steel, Mater. Sci. Technol., 2015, 31(7), p 843–856. https://doi.org/10.1179/1743284714Y.0000000722

Z. Zhang, F. Yang, H. Zhang, T. Zhang, H. Wang, Y. Xu, and Q. Ma, Influence of CeO2 Addition on Forming Quality and Microstructure of TiCx-Reinforced CrTi4-Based Laser Cladding Composite Coating, Mater. Charact., 2021, 171, p 110732. https://doi.org/10.1016/j.matchar.2020.110732

L. Liang, M. Xu, Y. Chen, T. Zhang, W. Tong, H. Liu, H. Wang, and H. Li, Effect of Welding Thermal Treatment on the Microstructure and Mechanical Properties of Nickel-Based Superalloy Fabricated by Selective Laser Melting, Mater. Sci. Eng. A, 2021, 819, p 141507. https://doi.org/10.1016/j.msea.2021.141507

C.D. Horvath, Chapter 2 - Advanced Steels for Lightweight Automotive Structures, Woodhead Publishing in Materials, P.K.B.T.-M. Mallick Design and Manufacturing for Lightweight Vehicles (Second Edition), Ed., Woodhead Publishing, 2021, p 39–95, https://doi.org/10.1016/B978-0-12-818712-8.00002-1.

H. Ashrafi, M. Shamanian, R. Emadi, S.E. Aghili, and E. Ghassemali, Damage Micromechanisms in Friction Stir-Welded DP600 Steel during Uniaxial Tensile Deformation, J. Mater. Eng. Perform., 2022, 31(12), p 10044–10053. https://doi.org/10.1007/s11665-022-06978-z

F. Eşiyok, R. Ertan, G. Sevilgen, E. Bulut, F. Öztürk, İ Alyay, and T.T. Abi, A Comparative Study on Conventional and Hybrid Quenching Hot Forming Methods of 22MnB5 Steel for Mechanical Properties and Microstructure, J. Mater. Eng. Perform., 2023, 32(3), p 1347–1356. https://doi.org/10.1007/s11665-022-07167-8

Y. Li, R. Wang, B. Wang, W. Ding, Influence of Silicon Addition on Intercritical Annealing Process and Tensile Properties of Medium Mn Steel. J. Mater. Sci., Springer US, 2021, 56(2), p 1783–1793, https://doi.org/10.1007/s10853-020-05330-x.

Z. Wang, J. Xu, and J. Li, Mechanical Properties and Fracture Behaviors of Medium-Mn Steels with and without Delta-Ferrite for Different Intercritical Annealing Times, Mater. Charact., 2021, 172, p 110730. https://doi.org/10.1016/j.matchar.2020.110730

Y. Li, F. Huyan, and W. Ding, Microstructure and Tensile Properties of a 0.20C–4.86Mn Steel after Short Intercritical- Annealing Times, Mater. Sci. Technol., 2019, 35(2), p 220–230. https://doi.org/10.1080/02670836.2018.1550864

D.M. Field, J. Qing, and D.C.V.A.N. Aken, Chemistry and Properties of Medium-Mn Two-Stage TRIP Steels. Metall. Mater. Trans. A, Springer US, 2018, 49(10), p 4615–4632, https://doi.org/10.1007/s11661-018-4798-6.

A. Perlade, A. Antoni, R. Besson, D. Caillard, J. Emo, A. Gourgues, P. Maugis, L. Thuinet, Q. Tonizzo, J. Schmitt, A. Perlade, A. Antoni, R. Besson, D. Caillard, J. Emo, A. Gourgues, P. Maugis, and A. Mestrallet, Development of 3rd Generation Medium Mn Duplex Steels for Automotive Applications, Mater. Sci. Technol., 2019, 35(2), p 204–219.

W. Ding, J. Du, and Y. Li, Transformations During Intercritical Annealing and Their Implications for Microstructure and Mechanical Properties of Medium Mn Transformation-Induced Plasticity Steel in Continuous Annealing Line, J. Mater. Eng. Perform., Springer US, 2020, 29(1), p 23–31.

H. Lee, M.C. Jo, S.S. Sohn, A. Zargaran, J.H. Ryu, N.J. Kim, and S. Lee, Novel Medium-Mn (Austenite + Martensite) Duplex Hot-Rolled Steel Achieving 1.6 GPa Strength with 20 % Ductility by Mn-Segregation-Induced TRIP Mechanism, Acta Mater., Elsevier Ltd, 2018, 147, p 247–260, https://doi.org/10.1016/j.actamat.2018.01.033.

J. Qiu, M. Zhang, X. Liu, X. Zhang, and Z. Tan, Materials Science & Engineering A Characterization of Retained Austenite in a Low Carbon High Strength Mn – Si – Cr Steel, Mater. Sci. Eng. A, Elsevier B.V., 2020, 797(August), p 139985, https://doi.org/10.1016/j.msea.2020.139985.

J. Liang, Z. Zhao, D. Tang, N. Ye, S. Yang, and W. Liu, Improved Microstructural Homogeneity and Mechanical Property of Medium Manganese Steel with Mn Segregation Banding by Alternating Lath Matrix, Mater. Sci. Eng. A, Elsevier B.V., 2018, 711(July 2017), p 175–181, https://doi.org/10.1016/j.msea.2017.11.046.

Y. Li, W. Ding, and B. Wang, Intercritical Annealing Pre-Treatment Used in a Hot- Dip Galvanised TRIP Steel, Mater. Sci. Technol., 2019, 35(11), p 1372–1380. https://doi.org/10.1080/02670836.2019.1625171

Z.C. Li, H. Ding, and Z.H. Cai, Mechanical Properties and Austenite Stability in Hot-Rolled 0.2C-1.6/3.2Al-6Mn-Fe TRIP Steel, Mater. Sci. Eng. A, 2015, 639, p 559–566.

H. Aydin, E. Essadiqi, I.H. Jung, and S. Yue, Development of 3rd Generation AHSS with Medium Mn Content Alloying Compositions, Mater. Sci. Eng. A, Elsevier, 2013, 564, p 501–508, https://doi.org/10.1016/j.msea.2012.11.113.

H. Xu, W. Cao, H. Dong, and J. Li, Effects of Aluminium on the Microstructure and Mechanical Properties in 0.2 C--5Mn Steels under Different Heat Treatment Conditions, ISIJ Int., The Iron and Steel Institute of Japan, 2015, 55(3), p 662–669.

W. Ding, R. Wang, Y. Li, and B. Wang, High Elongation of Medium-Manganese Steel Containing 1.0 Wt.% Al after a Short Intercritical Annealing Time, J. Mater. Res. Technol., 2020, 9(4), p 7262–7272.

A.L. Vidilli, L.B. Otani, W. Wolf, C.S. Kiminami, W.J. Botta, F.G. Coury, and C. Bolfarini, Design of a FeMnAlC Steel with TWIP Effect and Evaluation of Its Tensile and Fatigue Properties, J. Alloys Compd., Elsevier B.V, 2020, 831, p 154806, https://doi.org/10.1016/j.jallcom.2020.154806.

T. Bhattacharyya, S. Brat, S. Das, A. Haldar, and D. Bhattacharjee, Development and Characterisation of C – Mn – Al – Si – Nb TRIP Aided Steel, Mater. Sci. Eng. A Elsevier B.V., 2011, 528(6), p 2394–2400, https://doi.org/10.1016/j.msea.2010.11.054.

Z. Deng, M. Zhu, Y. Zhou, and D. Sichen, Attachment of Alumina on the Wall of Submerged Entry Nozzle during Continuous Casting of Al-Killed Steel, Metall. Mater. Trans. B Springer US, 2016, 47(3), p 2015–2025.

S. Jing, H. Ding, Y. Ren, and Z. Cai, A New Insight into Annealing Parameters in Tailoring the Mechanical Properties of a Medium Mn Steel, Scr. Mater. Elsevier Ltd, 2021, 202, p 114019. https://doi.org/10.1016/j.scriptamat.2021.114019

B.D.Cullity and S.R.Stock, “Elements of X-Ray Diffraction(3rd-Edition),” Prentice Hall, 2001.

S. Kang, J.G. Speer, D. Krizan, D.K. Matlock, and E. De Moor, Prediction of Tensile Properties of Intercritically Annealed Al-Containing 0.19C-4.5Mn (Wt%) TRIP Steels, Mater. Des., Elsevier Ltd, 2016, 97, p 138–146, https://doi.org/10.1016/j.matdes.2016.02.058.

Kang S, E. De Moor, and J.G. Speer, Retained Austenite Stabilization through Solute Partitioning during Intercritical Annealing in C-, Mn-, Al-, Si-, and Cr-Alloyed Steels, Metall. Mater. Trans. A, 2015, 46(MARCH), p 1005–1011.

B. Sun, F. Fazeli, C. Scott, N. Brodusch, R. Gauvin, and S. Yue, The Influence of Silicon Additions on the Deformation Behavior of Austenite-Ferrite Duplex Medium Manganese Steels, Acta Mater., Elsevier Ltd, 2018, 148, p 249–262, https://doi.org/10.1016/j.actamat.2018.02.005.

D.P. Koistinen and R.E. Marburger, A General Equation Prescribing the Extent of the Austenite-Martensite Transformation in Pure Iron-Carbon Alloys and Plain Carbon Steels, Acta Metall., 1959, 7(1), p 59–60. https://doi.org/10.1016/0001-6160(59)90170-1

S. Lee, S. Shin, M. Kwon, K. Lee, and B.C. De Cooman, Tensile Properties of Medium Mn Steel with a Bimodal UFG α + γ and Coarse δ-Ferrite Microstructure, Metall. Mater. Trans. A, 2017, 48(4), p 1678–1700. https://doi.org/10.1007/s11661-017-3979-z

O.A. Zambrano, Review A General Perspective of Fe – Mn – Al – C Steels, J. Mater. Sci., Springer US, 2018, 53(20), p 14003–14062, https://doi.org/10.1007/s10853-018-2551-6.

V. Shterner, I.B. Timokhina, and H. Beladi, On the Work-Hardening Behaviour of a High Manganese TWIP Steel at Different Deformation Temperatures, Mater. Sci. Eng. A, Elsevier, 2016, 669, p 437–446.

W. Püschl, Models for Dislocation Cross-Slip in Close-Packed Crystal Structures: A Critical Review, Prog. Mater. Sci., Elsevier, 2002, 47(4), p 415–461.

S. Liu, Z. Xiong, H. Guo, C. Shang, and R.D.K. Misra, The Significance of Multi-Step Partitioning: Processing-Structure-Property Relationship in Governing High Strength-High Ductility Combination in Medium-Manganese Steels, Acta Mater., Elsevier Ltd, 2017, 124, p 159–172, https://doi.org/10.1016/j.actamat.2016.10.067.

A. Dumay, J.-P. Chateau, S. Allain, S. Migot, and O. Bouaziz, Influence of Addition Elements on the Stacking-Fault Energy and Mechanical Properties of an Austenitic Fe–Mn–C Steel, Mater. Sci. Eng. A, 2008, 483–484, p 184–187. https://doi.org/10.1016/j.msea.2006.12.170

H. Luo and H. Dong, New Ultrahigh-Strength Mn-Alloyed TRIP Steels with Improved Formability Manufactured by Intercritical Annealing, Mater. Sci. Eng. A, Elsevier, 2015, 626, p 207–212, https://doi.org/10.1016/j.msea.2014.12.049.

J. Shi, X. Sun, M. Wang, W. Hui, H. Dong, and W. Cao, Enhanced Work-Hardening Behavior and Mechanical Properties in Ultrafine-Grained Steels with Large-Fractioned Metastable Austenite, Scr. Mater., Acta Materialia Inc., 2010, 63(8), p 815–818, https://doi.org/10.1016/j.scriptamat.2010.06.023.

D.M. Pallisco and J.R. McDermid, Mechanical Property Development of a 0.15C–6Mn–2Al–1Si Third-Generation Advanced High Strength Steel Using Continuous Galvanizing Heat Treatments, Mater. Sci. Eng. A, 2020, 778, p 139111, https://doi.org/10.1016/j.msea.2020.139111.

H.F. Xu, J. Zhao, W.Q. Cao, J. Shi, C.Y. Wang, C. Wang, J. Li, and H. Dong, Heat Treatment Effects on the Microstructure and Mechanical Properties of a Medium Manganese Steel (0.2C–5Mn), Mater. Sci. Eng. A, 2012, 532(5), p 435–442.

J. Hu, W. Cao, C. Huang, C. Wang, H. Dong, and J. Li, Characterization of Microstructures and Mechanical Properties of Cold-Rolled Medium-Mn Steels with Different Annealing Processes, ISIJ Int., 2015, 55(10), p 2229–2236.

R. Sun, W. Xu, C. Wang, J. Shi, H. Dong, and W.C. Ã, Work Hardening Behavior of Ultrafine Grained Duplex Medium-Mn Steels Processed by ART-Annealing, Steel Res. Int., 2012, 83(4), p 316–321.

J. Chiang, B. Lawrence, J.D. Boyd, and A.K. Pilkey, Effect of Microstructure on Retained Austenite Stability and Work Hardening of TRIP Steels, Mater. Sci. Eng. A, Elsevier, 2011, 528(13–14), p 4516–4521, https://doi.org/10.1016/J.MSEA.2011.02.032.

J. Qiu, M. Zhang, X. Liu, X. Zhang, and Z. Tan, The Study of the Planar Defects of the Nano-Sized Retained Austenite in Mn-Si-Cr Steel, Mater. Lett., Elsevier B.V., 2020, 266, p 127510, https://doi.org/10.1016/j.matlet.2020.127510.

S.-J. Lee and K.-S. Park, Prediction of Martensite Start Temperature in Alloy Steels with Different Grain Sizes, Metall. Mater. Trans. A, Springer, 2013, 44(8), p 3423–3427.

K. Sugimoto, M. Misu, M. Kobayashi, and H. Shirasawa, Effects of Second Phase Morphology on Retained Austenite Morphology and Tensile Properties in a Trip-Aided Dual-Phase Steel Sheet, ISIJ Int., 1993, 33(7), p 775–782. https://doi.org/10.2355/isijinternational.33.775

P. Jacques, Q. Furnémont, T. Pardoen, and F. Delannay, On the Role of Martensitic Transformation on Damage and Cracking Resistance in TRIP-Assisted Multiphase Steels, Acta Mater., 2001, 49(1), p 139–152.

Y. Tian, O.I. Gorbatov, A. Borgenstam, A. V. Ruban, and P. Hedström, Deformation Microstructure and Deformation-Induced Martensite in Austenitic Fe-Cr-Ni Alloys Depending on Stacking Fault Energy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2017, 48(1), p 1–7.

J. Talonen and H. Hänninen, Formation of Shear Bands and Strain-Induced Martensite during Plastic Deformation of Metastable Austenitic Stainless Steels. Acta Mater., Elsevier, 2007, 55(18), p 6108–6118.

R.S. Mishra, S.S. Nene, M. Frank, S. Sinha, K. Liu, and S. Shukla, Metastability Driven Hierarchical Microstructural Engineering: Overview of Mechanical Properties of Metastable Complex Concentrated Alloys, J. Alloys Compd., Elsevier BV., 2020, p 155625, https://doi.org/10.1016/j.jallcom.2020.155625.

G. Sun, M. Zhao, L. Du, and H. Wu, Significant Effects of Grain Size on Mechanical Response Characteristics and Deformation Mechanisms of Metastable Austenitic Stainless Steel, Mater. Charact., 2022, 184, p 111674. https://doi.org/10.1016/j.matchar.2021.111674

Acknowledgements

This study was funded by the Natural Science Foundation of Inner Mongolia (2020LH05026), and the National International Science and Technology Cooperation Base on Railway Vehicle Operation Engineering of Beijing Jiaotong University (BMRV21KF02).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ding, W., Zhang, N., Zhang, G. et al. Microstructure and Mechanical Properties of Medium Manganese Steel with Different Aluminum Addition After Very Short Time Intercritical Annealing. J. of Materi Eng and Perform 33, 2015–2026 (2024). https://doi.org/10.1007/s11665-023-08083-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08083-1