Abstract

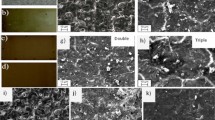

Wearable device shell materials will inevitably be corroded by human sweat during use. The purpose of this study is to construct three composite films of CrSiCN, CrBCN and CrSiBCN with corrosion resistance on silicon wafers and 316L stainless steel substrates by using closed-field unbalanced magnetron sputtering technology as protective films, to protect the corrosion of shell materials. The electrochemical behavior of Si and B element doped films under acidic and alkaline artificial sweat was studied by electrochemical noise, AC impedance and potentiodynamic polarization electrochemical measurement techniques, and the microstructural changes of the films were characterized by scanning electron microscopy, x-ray diffraction and laser Raman spectroscopy. Electrochemical test results show that the films exhibit a higher corrosion rate compared to alkaline artificial sweat due to the higher concentration of chloride ions, hydrogen ions, and lactic acid corrosive ions in acidic artificial sweat. The results also demonstrated that the inhibitory effect of a high concentration of hydrogen ions in acidic artificial sweat resulted in a relatively low surface oxygen content, whereas the doping of the boron element promoted the growth of passive film on the coating surface, thereby decreasing the corrosion rate of CrBCN film in acidic sweat. Furthermore, the high concentration of hydroxyl ions in alkaline artificial sweat accelerates the electrochemical reactions of passive film growth (mainly chromium oxides and hydroxides), hence enhancing the corrosion resistance of the CrSiCN film with its denser and smoother surface.

Similar content being viewed by others

References

G. Matzeu, L. Florea and D. Diamond, Advances in Wearable Chemical Sensor Design for Monitoring Biological Fluids, Sens. Actuators B Chem., 2015, 211, p 403–418.

X. Wang, Z. Liu and T. Zhang, Flexible Sensing Electronics for Wearable/Attachable Health Monitoring, Small, 2017, 13(25), p 1602790.

A.M. Fekry, A.A. Ghoneim and M.A. Ameer, Electrochemical Impedance Spectroscopy of Chitosan Coated Magnesium Alloys in a Synthetic Sweat Medium, Surf. Coat. Technol., 2014, 238, p 126–132.

Y.W. Song, D.Y. Shan and E.H. Han, Corrosion Behaviors of Electroless Plating Ni–P Coatings Deposited on Magnesium Alloys in Artificial Sweat Solution, Electrochim. Acta., 2007, 53(4), p 2009–2015.

C. Prakash, P. Bhargava, S. Tiwari, B. Majumdar and R.K. Bhargava, Skin Surface pH in Acne Vulgaris: Insights from an Observational Study and Review of the Literature, J. Clin. Aesthet. Dermatol., 2017, 10(7), p 33–39.

S.C. Ferreira, E. Ariza, L.A. Rocha, J.R. Gomes, P. Carvalho, F. Vaz, A.C. Fernandes, L. Rebouta, L. Cunha, E. Alves, P. Goudeau and J.P. Rivière, Tribocorrosion Behaviour of ZrOxNy Thin Films for Decorative Applications, Surf. Coat. Technol., 2006, 200(22), p 6634–6639.

C. Ji, Q. Guo, J. Li, Y. Guo, Z. Yang, W. Yang, D. Xu and B. Yang, Microstructure and Properties of CrN Coating via Multi-arc Ion Plating on the Valve Seat Material Surface, J. Alloys Compd., 2022, 891, p 161966.

M.S.I. Chowdhury, B. Bose, K. Yamamoto, L.S. Shuster, J. Paiva, G.S. Fox-Rabinovich and S.C. Veldhuis, Wear Performance Investigation of PVD Coated and Uncoated Carbide Tools During High-speed Machining of Ti6Al4V Aerospace Alloy, Wear, 2020, 446–447, p 203168.

G. Berg, C. Friedrich, E. Broszeit and C. Berger, Development of Chromium Nitride Coatings Substituting Titanium Nitride, Surf. Coat. Technol., 1996, 86–87, p 184–191.

A. Vereschaka, V. Tabakov, S. Grigoriev, N. Sitnikov, F. Milovich, N. Andreev and J. Bublikov, Investigation of Wear Mechanisms for the Rake Face of a Cutting Tool with a Multilayer Composite Nanostructured Cr–CrN-(Ti, Cr, Al, Si)N Coating in High-speed Steel Turning, Wear, 2019, 438–439, 203069.

J.-H. Park, H.-G. Kim, J.-Y. Park, Y.-I. Jung, D.-J. Park and Y.-H. Koo, High Temperature Steam-Oxidation Behavior of Arc Ion Plated Cr Coatings for Accident Tolerant Fuel Claddings, Surf. Coat. Technol., 2015, 280, p 256–259.

C. Liu, Q. Bi and A. Matthews, EIS Comparison on Corrosion Performance of PVD TiN and CrN Coated Mild Steel in 0.5 N NaCl Aqueous Solution, Corros. Sci., 2001, 43(10), p 1953–1961.

C. Petrogalli, L. Montesano, M. Gelfi, G.M. La Vecchia and L. Solazzi, Tribological and Corrosion Behavior of CrN Coatings: Roles of Substrate and Deposition Defects, Surf. Coat. Technol., 2014, 258, p 878–885.

P. Panjan, M. Čekada, M. Panjan, D. Kek-Merl, F. Zupanič, L. Čurković and S. Paskvale, Surface Density of Growth Defects in Different PVD Hard Coatings Prepared by Sputtering, Vacuum, 2012, 86(6), p 794–798.

S. Khamseh, E. Alibakhshi, B. Ramezanzadeh, J.-S. Lecomte, P. Laheurte, X. Noirefalize, F. Laoutid and H. Vahabi, Tailoring Hardness and Electrochemical Performance of TC4 Coated Cu/a-C Thin Coating with Introducing Second Metal Zr, Corros. Sci., 2020, 172, 108713.

S. Khamseh, E. Alibakhshi, M. Mahdavian, M.R. Saeb, H. Vahabi, N. Kokanyan and P. Laheurte, Magnetron-Sputtered Copper/Diamond-Like Carbon Composite Thin Films with Super Anti-corrosion Properties, Surf. Coat. Technol., 2018, 333, p 148–157.

P. Wieciński, J. Smolik, H. Garbacz and K.J. Kurzydłowski, Failure and Deformation Mechanisms During Indentation in Nanostructured Cr/CrN Multilayer Coatings, Surf. Coat. Technol., 2014, 240, p 23–31.

K. Holmberg, A. Matthews and H. Ronkainen, Coatings Tribology—Contact Mechanisms and Surface Design, Tribol. Int., 1998, 31(1), p 107–120.

H. Kindlund, D.G. Sangiovanni, I. Petrov, J.E. Greene and L. Hultman, A Review of the Intrinsic Ductility and Toughness of Hard Transition-Metal Nitride Alloy Thin Films, Thin Solid Films, 2019, 688, 137479.

J. Lin, J. Jang, I.-W. Park and R. Wei, Structure and Properties of CrSiCN Coatings Deposited by Pulsed dc Magnetron Sputtering for Wear and Erosion Protection, Surf. Coat. Technol., 2016, 287, p 44–54.

F. Cai, X. Huang and Q. Yang, Mechanical Properties, Sliding Wear and Solid Particle Erosion Behaviors of Plasma Enhanced Magnetron Sputtering CrSiCN Coating Systems, Wear, 2015, 324–325, p 27–35.

F. Cai, X. Huang, Q. Yang, R. Wei and D. Nagy, Microstructure and Tribological Properties of CrN and CrSiCN Coatings, Surf. Coat. Technol., 2010, 205(1), p 182–188.

Q. Wang, F. Zhou, L. Zhu, M. Zhang and J. Kong, Mechanical and Tribological Evaluation of CrSiCN, CrBCN and CrSiBCN Coatings, Tribol. Int., 2019, 130, p 146–154.

Z. Wu, F. Zhou, Q. Ma, Q. Wang, Z. Zhou and L. Kwok-Yan Li, Tribological and Electrochemical Properties of Cr–Si–C–N Coatings in Artificial Seawater, RSC Adv., 2016, 6(80), p 76724–76735.

F. Zhou, Q. Ma, Q. Wang, Z. Zhou and L.K.-Y. Li, Electrochemical and Tribological Properties of CrBCN Coatings with Various B Concentrations in Artificial Seawater, Tribol. Int., 2017, 116, p 19–25.

Q. Ma, F. Zhou, Q. Wang, Z. Wu, K. Chen, Z. Zhou and L. Kwok-Yan Li, Influence of CrB2 Target Current on the Microstructure, Mechanical and Tribological Properties of Cr–B–C–N Coatings in Water, RSC Adv., 2016, 6(53), p 47698–47711.

M.M. Puurtinen, S.M. Komulainen, P.K. Kauppinen, J.A.V. Malmivuo, and J.A.K. Hyttinen. Measurement of noise and impedance of dry and wet textile electrodes, and textile electrodes with hydrogel, in 2006 International Conference of the IEEE Engineering in Medicine and Biology Society (2006).

K. Hladky and J.L. Dawson, The Measurement of Corrosion Using Electrochemical 1f Noise, Corros. Sci., 1982, 22(3), p 231–237.

P. Pedrosa, D. Machado, P. Fiedler, E. Alves, N.P. Barradas, J. Haueisen, F. Vaz and C. Fonseca, Electrochemical and Structural Characterization of Nanocomposite Agy:TiNx Thin Films for Dry Bioelectrodes: the Effect of the N/Ti Ratio and Ag Content, Electrochim. Acta., 2015, 153, p 602–611.

D.A. Eden, M. Hoffman, and B.S. Skerry, Application of electrochemical noise measurements to coated systems R.A. Dickie, F.L. Floyd (Eds.), Polym. Mater. Corros. Control, American Chemical Society, Washington, DC (1986), Chapter 4, p 36–47.

J. Riskin, Chapter 5—corrosion behavior investigations of traditional structural metallic materials in electrochemical plant media, taking into account attack by leakage currents, Electrocorrosion and Protection of Metals. J. Riskin Ed., Elsevier, Amsterdam, 2008, p 69–78

A. Bishnoi, S. Kumar and N. Joshi, Chapter 9—wide-angle X-ray diffraction (WXRD): technique for characterization of nanomaterials and polymer nanocomposites, Microscopy Methods in Nanomaterials Characterization. S. Thomas, R. Thomas, A.K. Zachariah, R.K. Mishra Ed., Elsevier, Amsterdam, 2017, p 313–337

M. Isakhani-Zakaria, S.R. Allahkaram and H.A.J.C.S. Ramezani-Varzaneh, Evaluation of Corrosion Behaviour of Pb-Co3O4 Electrodeposited Coating Using EIS Method, Corros. Sci., 2019, 157, p 472–480.

X. Zhang, S.O. Pehkonen, N. Kocherginsky and G. Andrew Ellis, Copper Corrosion in Mildly Alkaline Water with the Disinfectant Monochloramine, Corros. Sci., 2002, 44(11), p 2507–2528.

J. Tedim, A.C. Bastos, S. Kallip, M.L. Zheludkevich and M.G.S. Ferreira, Corrosion Protection of AA2024-T3 by LDH Conversion Films. Analysis of SVET Results, Electrochim. Acta, 2016, 210, p 215–224.

J. Lu, Y. Zhao, H. Niu, Y. Zhang, Y. Du, W. Zhang and W. Huo, Electrochemical Corrosion Behavior and Elasticity Properties of Ti–6Al–xFe Alloys for Biomedical Applications, Mater. Sci. Eng. C, 2016, 62, p 36–44.

X. Yang, M. Gao, Y. Liu, J. Li, Y. Huang, G. Wang, J.-Q. Wang and J. Huo, Superior Corrosion Resistance of High-Temperature Ir–Ni–Ta–(B) Amorphous Alloy in Sulfuric Acid Solution, Corros. Sci., 2022, 200, p 110227.

A.S.O. Gomes, N. Yaghini, A. Martinelli and E. Ahlberg, A Micro-Raman Spectroscopic Study of Cr(OH)3 and Cr2O3 Nanoparticles Obtained by the Hydrothermal Method, J. Raman Spectrosc., 2017, 48(10), p 1256–1263.

P. Li, Z. Zhou, H. Xu and Y. Zhang, A novel hydrolysis method to synthesize chromium hydroxide nanoparticles and its catalytic effect in the thermal decomposition of ammonium perchlorate, Thermochim. Acta., 2012, 544, p 71–76.

Acknowledgment

This work has been supported by National Natural Science Foundation of China (Grant No. 51775271). We would like to acknowledge for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qian, J., Zhou, F., Zhang, M. et al. Comparison of Electrochemical Properties of CrSiCN, CrBCN, and CrSiBCN Films in Acidic and Alkaline Artificial Sweat. J. of Materi Eng and Perform 33, 1131–1142 (2024). https://doi.org/10.1007/s11665-023-08078-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08078-y