Abstract

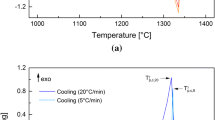

Differential scanning calorimetry (DSC) and confocal scanning laser microscopy (CSLM) were used to investigate the effects of different cooling rates on the solidification and segregation characteristics of Cu-Ni-Si alloy. The microstructures were characterized by electron probe microanalysis and scanning electron microscope. The effects of cooling rate on segregation degree, grain size, solidification temperature and secondary dendrite spacing (λ2) were analyzed, and the correlation function was established. The results show that the characteristic temperature of DSC phase transformation is similar to the characteristic temperature of CSLM in situ microstructure evolution. Increasing cooling rate can reduce segregation degree and refine grains. The relationships between cooling rate and crystallization temperature (TL→S) and secondary dendrite spacing (λ2) with cooling rate are as follows: TL→S = 176 × exp(− v/17.6) + 891 and λ2 = 63 × v−0.236, respectively. The above relations were applied to predict the solidification microstructure characteristics produced by twin-roll strip casting and ingot casting processes, and the predicted results are in good agreement with the experimental values. The advantages of grain refinement and segregation improvement and its optimization mechanism of twin-roll strip casting have been clarified.

Similar content being viewed by others

References

Q. Lei, Z. Li, T. Xiao, Y. Pang, Z.Q. Xiang, W.T. Qiu, and Z. Xiao, A New Ultrahigh Strength Cu-Ni-Si Alloy, J. Intermet., 2013, 42, p 77–84. https://doi.org/10.1016/j.intermet.2013.05.013

Q. Lei, Z. Li, M.P. Wang, L. Zhang, Z. Xiao, and Y.L. Jia, The Evolution of Microstructure in Cu-8.0 Ni-1.8 Si-0.15 Mg Alloy During Aging, Mater. Sci. Eng. A, 2010, 527(24–25), p 6728–6733. https://doi.org/10.1016/j.msea.2010.07.023

Z.Y. Pan, M.P. Wang, Z. Li, Z. Xiao, and C. Chen, Thermomechanical Treatment of Super High Strength Cu-8.0Ni-1.8Si Alloy, Trans. Nonferrous Met. Soc. China, 2007, 17, p 1076–1080.

Q. Dong, D. Zhao, P. Liu, B.K. Kang, and J.L. Huang, Microstructural Changes of Cu-Ni-Si Alloy During Aging, J. Mater. Sci. Technol., 2004, 20, p 99–102.

Z. Rdzawski and J. Stobrawa, Thermomechanical Processing of Cu-Ni-Si-Cr-Mg Alloy, Mater. Sci. Technol., 1993, 2(12), p 142–145. https://doi.org/10.1179/026708393790171836

K.M. Sun, L. Li, S.D. Chen, G.M. Xu, G. Chen, R.D.K. Misra, and G. Zhang, A New Approach to Control Centerline Macrosegregation in Al-Mg-Si Alloys During Twin Roll Continuous Casting, Mater. Lett., 2017, 190, p 205–208. https://doi.org/10.1016/j.matlet.2016.12.109

G.M. Cao, S. Zhang, J. Chen, F. Jia, F. Fang, and C.G. Li, Microstructure and Precipitate Evolution in Cu-3.2Ni-0.75Si Alloy Processed by Twin-Roll Strip Casting, J. Mater. Eng. Perform., 2021, 30(2), p 1318–1329. https://doi.org/10.1007/s11665-020-05371-y

Z.Y. Liu, Z.S. Lin, S.H. Wang, Y.Q. Qiu, X.H. Liu, and G.D. Wang, Microstructure Characterization of Austenitic Fe-25Mn-22Cr-2Si-0.7N Alloy Processed by Twin Roll Strip Casting, Mater. Charact., 2007, 58, p 974–979. https://doi.org/10.1016/j.matchar.2006.10.005

M. Daamen, C. Haase, J. Dierdorf, D.A. Molodov, and G. Hirt, Twin-Roll Strip Casting: A Competitive Alternative for the Production of High-Manganese Steels with Advanced Mechanical Properties, Mater. Sci. Eng. A, 2015, 627, p 72–81. https://doi.org/10.1016/j.msea.2014.12.069

K.S. Pandey, S.K. Pandey, and P. Premkumar, Effect of Cooling Rates on Dendritic Arm Spacing and Hardness of Zn-12%, A1-0.3% Cu Alloy, Indian Foundry J, 1979, 25(12), p 29–32.

M.J. Behnam, P. Davami, and N. Varahram, Effect of Cooling Rate on Microstructure and Mechanical Properties of Gray Cast Iron, Mater. Sci. Eng. A, 2010, 528(2), p 583–588. https://doi.org/10.1016/j.msea.2010.09.087

E. Wielgosz and T. Kargul, Differential Scanning Calorimetry Study of Peritectic Steel Grades, J. Therm. Anal. Calorim., 2015, 119, p 1547–1553. https://doi.org/10.1007/s10973-014-4302-5

Z.J. Miao, A.D. Shan, W. Wang, J. Lu, W.L. Xu, and H.W. Song, Solidification Process of Conventional Superalloy by Confocal Scanning Laser Microscope, Trans. Nonferrous Met. Soc., 2011, 21(2), p 236–242. https://doi.org/10.1016/S1003-6326(11)60704-8

K. Hechu, C. Slater, B. Santillana, S. Clark, and S. Sridhar, A Novel Approach for Interpreting the Solidification Behaviour of Peritectic Steels by Combining CSLM and DSC, Mater. Charact., 2017, 133, p 25–32. https://doi.org/10.1016/j.matchar.2017.09.013

P.H. Nicácio, A.M. Severo, A.B. Barros, A.K. Albuquerque, R.M. Wellen, and K. Koschek, Approaches on the Complex Crystallization in PLA/Babassu Based on Modulated Differential Scanning Calorimetry Analyses, J. Polym. Environ., 2022, 30(9), p 3840–3851. https://doi.org/10.1007/s10924-022-02468-4

J.Y. Cheng, B.B. Tang, F.X. Yu, and B. Shen, Evaluation of Nanoscaled Precipitates in a Cu-Ni-Si-Cr Alloy During Aging, Alloys Compd., 2014, 614, p 189–195. https://doi.org/10.1016/j.jallcom.2014.06.089

Y.S. Hao, J. Li, X. Li, W.C. Liu, G.M. Cao, C.G. Li, and Z.Y. Liu, Influences of Cooling Rates on Solidification and Segregation Characteristics of Fe-Cr-Ni-Mo-N Super Austenitic Stainless Steel, J. Mater. Process. Technol., 2019, 275, p 116326. https://doi.org/10.1016/j.jmatprotec.2019.116326

Y. Xu, N. Ellendt, X.G. Li, V. Uhlenwinkel, and U. Fritsching, Characterization of Cooling Rate and Microstructure of CuSn Melt Droplet in Drop on Demand Process, Trans. Nonferrous Met. Soc. China, 2017, 27(7), p 1636–1644. https://doi.org/10.1016/S1003-6326(17)60186-9

J.W. Elmer, S.M. Allen, and T.W. Eagar, Microstructural Development During Solidification of Stainless-Steel Alloys, Metall. Mater. Trans. A, 1989, 20(10), p 2117–2131. https://doi.org/10.1007/BF02650298

J.H. Perepezko and G. Wilde, Melt Undercooling and Nucleation Kinetics, Curr. Opin. Solid St. M, 2016, 20, p 3–12. https://doi.org/10.1016/j.cossms.2015.07.001

M. Gholami, I. Altenberger, J. Vesely, H.A. Kuhn, M. Wollmann, M. Janecek, and L. Wagner, Effects of Severe Plastic Deformation on Transformation Kinetics of Precipitates in CuNi3Si1Mg, Mater. Sci. Eng. A, 2016, 676, p 156–164. https://doi.org/10.1016/j.msea.2016.08.099

L.S. Tian, Y.C. Guo, J.P. Li, F. Xia, M.X. Liang, and Y.P. Bai, Effects of Solidification Cooling Rate on the Microstructure and Mechanical Properties of a Cast Al-Si-Cu-Mg-Ni Piston Alloy, Adv. Mater., 2018 https://doi.org/10.3390/ma11071230

X. Li, F. Gao, J.H. Jiao, G.M. Cao, Y. Wang, and Z.Y. Liu, Influences of Cooling Rates on Delta Ferrite of Nuclear Power 316H Austenitic Stainless Steel, Mater. Charact., 2021, 174, p 111029. https://doi.org/10.1016/j.matchar.2021.111029

E. Wielgosz and T. Kargul, Differential Scanning Calorimetry Study of Peritectic Steel Grades, J. Therm. Anal. Calorim., 2015, 119, p 1547–1553. https://doi.org/10.1007/s10973-014-4302-5

Y.M. Won and B.G. Thomas, Simple Model of Microsegregation During Solidification of Steels, Metall. Mater. Trans. A, 2001, 32, p 1755–1767. https://doi.org/10.1007/s11661-001-0152-4

H.T. Liu, Z.H. Liu, Y.Q. Qiu, G.M. Cao, C.C. Li, and G.D. Wang, Characterization of the Solidification Structure and Texture Development of Ferritic Stainless Steel Produced by Twin-roll Strip Casting, Mater. Charact., 2009, 60(1), p 79–82. https://doi.org/10.1016/j.matchar.2008.06.005

G. Li, W. Yu, and Q. Cai, Investigation of Reduction Pretreatment Process for Continuous Casting, J. Mater. Process. Technol., 2016, 227, p 41–48. https://doi.org/10.1016/j.jmatprotec.2015.08.005

T. Xiao, X.F. Sheng, Q. Lei, J.L. Zhu, S.Y. Li, Z.R. Liu, and Z. Li, Effect of Magnesium on Microstructure Refinements and Properties Enhancements in High-Strength Cu-Ni-Si Alloys, Acta Metall. Sin. (Engl. Lett.), 2020, 33, p 375–384. https://doi.org/10.1007/s40195-019-00953-9

Acknowledgments

This work was supported by the National MCF (Magnetic Confinement Fusion) Energy R&D Program of China (with Grant No. 2018YFE0306102) and the Postdoctoral Science Foundation of China (Grant No. 2021M701167).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, G., Li, R., Zhang, S. et al. Influence of Cooling Rate on Solidification and Segregation Characteristics of Cu-Ni-Si Alloy. J. of Materi Eng and Perform 33, 1274–1282 (2024). https://doi.org/10.1007/s11665-023-08067-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08067-1