Abstract

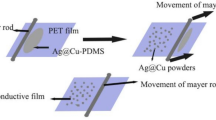

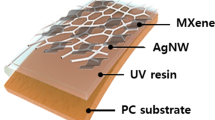

With the expansion of the applications of sensors, requirements such as flexibility, visual transparency, and self-powering have become critical. In this work, firstly we have adopted photoetch and hierarchical (micro-nano) manufacturing techniques to fabricate a micro-scale copper grid on polyethylene terephthalate (PET). This material (Cu grid @PET) exhibits high transmittance (89% at 550 nm, only 2.7% lower than PET substrate) and low electric resistance (6.7 Ω sq−1) compared with other reports. Then, the as-fabricated Cu grid @PET composite electrode, poly-dimethylsiloxane (PDMS), and polymethyl methacrylate (PMMA) were utilized to fabricate a sandwich-like structured transparent self-powered sensor (TSPFS) with high optical transmittance of 85.5-87.5% (450 ~ 620 nm). A complete novel control method combining with sensor’s electrical signal test was implemented by Dynamic Mechanical Analyzer (DMA), verifying the simulation response to space of COMSOL. Voltage signals could be also observed when the sensor was touched by fingers without receiving electric energy from external sources. Finally, the paper shows a kind of smart goggles made of the produced transparent device, exhibiting heating, antifogging, and sensing functions.

Similar content being viewed by others

References

Q. Zhao et al., Highly sensitive, reliable and flexible pressure sensor based on piezoelectric PVDF hybrid film using MXene nanosheet reinforcement, J. Alloy. Compd., 2021, 886, 161069.

Z. Qiao et al., Study of flexible piezoresistive sensors based on the hierarchical porous structure CNT /PDMS composite materials, J. Alloy. Compd., 2022, 917, 165503.

P.S. Khiabani et al., Fabrication of In2O3 based NO2 gas sensor through AC-electrophoretic deposition, Sens. Actuators, B Chem., 2012, 166–167, p 128–134.

S.S. SebtAhmadi et al., General modeling and experimental observation of size dependence surface activity on the example of Pt nano-particles in electrochemical CO gas sensors, Sens. Actuators, B Chem., 2019, 285, p 310–316.

M. Shaker, R. Riahifar and Y. Li, A review on the superb contribution of carbon and graphene quantum dots to electrochemical capacitors’ performance: Synthesis and application, FlatChem, 2020, 22, 100171.

G.-Y. Li et al., Hierarchical PVDF-HFP/ZnO composite nanofiber–based highly sensitive piezoelectric sensor for wireless workout monitoring, Adv. Comp. Hybrid Mater., 2021, 5(2), p 766–775.

S. Yu et al., All-solution-processed molybdenum oxide-encapsulated silver nanowire flexible transparent conductors with improved conductivity and adhesion, ACS Appl. Mater. Interfaces., 2021, 13(12), p 14470–14478.

J. Luo et al., Durable and flexible Ag-nanowire-embedded PDMS films for the recyclable swabbing detection of malachite green residue in fruits and fingerprints, Sens. Actuat., B Chem., 2021, 347, 130602.

M. Fan et al., A highly stretchable natural rubber/buckypaper/natural rubber (NR/N-BP/NR) sandwich strain sensor with ultrahigh sensitivity, Adv. Comp. Hybrid Mater., 2021, 4(4), p 1039–1047.

X. Leng et al., Technology and applications of graphene oxide membranes, Molecular interactions on two-dimensional materials. World Scientific, 2022, p 379–422

A. Waseem et al., Flexible self-powered piezoelectric pressure sensor based on GaN/p-GaN coaxial nanowires, J. Alloy. Compd., 2021, 872, 159661.

L. He et al., A novel self-powered sensor based on Ni(OH)2/Fe2O3 photoanode for glucose detection by converting solar energy into electricity, J. Alloy. Compd., 2022, 907, 164132.

M. Zhang et al., Fabrication and applications of cellulose-based nanogenerators, Adv. Comp. Hybr. Mater., 2021, 4(4), p 865–884.

H. Salehi et al., A comprehensive review of self-powered sensors in civil infrastructure: state-of-the-art and future research trends, Eng. Struct., 2021, 234, 111963.

Q. Zhou et al., Portable triboelectric microfluidic system for self-powered sensors towards in-situ detection, Nano Energy, 2021, 85, 105980.

K.Y. Fang et al., A low-frequency vibration energy harvester employing self-biased magnetoelectric composite, Sens. Actuat. A: Phys., 2021 https://doi.org/10.1016/j.sna.2021.113066

W. Zhao et al., Understanding piezoelectric characteristics of PHEMA-based hydrogel nanocomposites as soft self-powered electronics, Adv. Comp. Hybr. Mater., 2018, 1(2), p 320–331.

P. Bahoumina et al., Microwave flexible gas sensor based on polymer multi wall carbon nanotubes sensitive layer, Sens. Actuat., B Chem., 2017, 249, p 708–714.

S.S. Ahmadi et al., Fabrication of counter electrode of electrochemical CO gas sensor by electrophoretic deposition of MWCNT, J. Electrochem. Soc., 2015, 162(11), p D3101.

Y. Jung et al., Flexible and highly sensitive three-axis pressure sensors based on carbon nanotube/polydimethylsiloxane composite pyramid arrays, Sens. Actuators, A, 2021, 331, 113034.

X. Leng et al., Introduction to two-dimensional materials, Molecular interactions on two-dimensional materials. World Scientific, 2022, p 1–41

H. Jeong et al., Flexible resistive pressure sensor with silver nanowire networks embedded in polymer using natural formation of air gap, Compos. Sci. Technol., 2019, 174, p 50–57.

J. Li et al., Flexible NWs sensors in polymer, metal oxide and semiconductor materials for chemical and biological detection, Sens. Actuators, B Chem., 2015, 219, p 65–82.

Y. Maithani et al., Self-adhesive, stretchable, and dry silver nanorods embedded polydimethylsiloxane biopotential electrodes for electrocardiography, Sens. Actuat., A, 2021, 332, 113068.

F. Martinez et al., Polymer-based flexible strain sensor, Procedia Chem., 2009, 1(1), p 915–918.

S.S. Ahmadi et al., Electrophoretic deposition of MWCNT on a PTFE layer for making working electrode of oxygen sensor, J. Electrochem. Soc., 2017, 164(12), p B506.

W. Chen and X. Yan, Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: a review, J. Mater. Sci. Technol., 2020, 43, p 175–188.

D. Kannichankandy et al., Flexible piezo-resistive pressure sensor based on conducting PANI on paper substrate, Synth. Met., 2021, 273, 116697.

G. Wang et al., Flexible pressure sensor based on PVDF nanofiber, Sens. Actuators, A, 2018, 280, p 319–325.

Q. Wu et al., An enhanced flexible room temperature ammonia gas sensor based on GP-PANI/PVDF multi-hierarchical nanocomposite film, Sens. Actuators, B Chem., 2021, 334, 129630.

A. Elschner et al., PEDOT: principles and applications of an intrinsically conductive polymer, CRC Press, Florida, 2010.

Q. Wang et al., Biocompatible, self-wrinkled, antifreezing and stretchable hydrogel-based wearable sensor with PEDOT: sulfonated lignin as conductive materials, Chem. Eng. J., 2019, 370, p 1039–1047.

S. Bae et al., Roll-to-roll production of 30-inch graphene films for transparent electrodes, Nat. Nanotechnol., 2010, 5(8), p 574–578.

Y.-H. Yoon et al., Transparent film heater using single-walled carbon nanotubes, Adv. Mater., 2007, 19(23), p 4284–4287.

Z. Zhong et al., Continuous patterning of copper nanowire-based transparent conducting electrodes for use in flexible electronic applications, ACS Nano, 2016, 10(8), p 7847–7854.

C.-B. Huang et al., Highly sensitive strain sensors based on molecules-gold nanoparticles networks for high-resolution human pulse analysis, Small, 2021, 17(8), p 2007593.

H. Zhou and Y. Song, Fabrication of silver mesh/grid and its applications in electronics, ACS Appl. Mater. Interfaces., 2021, 13(3), p 3493–3511.

S. Yu et al., Highly stable silver nanowire networks with tin oxide shells for freestanding transparent conductive nanomembranes through all-solution processes, Chem. Eng. J., 2022, 446, 137481.

X. Chen et al., Printable high-aspect ratio and high-resolution cu grid flexible transparent conductive film with figure of merit over 80 000, Adv. Electr. Mater., 2019, 5(5), p 1800991.

W. Cao et al., Large-scale fabrication of graphene/polyamide-6 composite as a high thermal conductivity engineering composite for thermal radiators, Mater. Lett., 2022, 316, 132036.

M. Shaker et al., The effect of graphene orientation on permeability and corrosion initiation under composite coatings, Constr. Build. Mater., 2022, 319, 126080.

V.Z. Asl et al., Corrosion properties and surface free energy of the Zn-Al LDH/rGO coating on MAO pretreated AZ31 magnesium alloy, Surf. Coat. Tech., 2021, 426, 127764.

P. Bellchambers et al., High-performance transparent copper grid electrodes fabricated by microcontact lithography for organic photovoltaics, ACS Appl. Energy Mater., 2021, 4(4), p 4150–4155.

S. Yu et al., Flexible transparent Ag nanowire/UV-curable resin heaters with ultra-flexibility, high transparency, quick thermal response, and mechanical reliability, J. Alloy. Compd., 2022, 908, 164690.

S. Yu et al., Enhanced conductivity and stability of Cu-embedded zinc tin oxide flexible transparent conductive thin films, Ceram. Int., 2022, 48(11), p 15925–15931.

L. Li et al., Transparent Ag@ Au–graphene patterns with conductive stability via inkjet printing, J. Mater. Chem. C, 2017, 5(11), p 2800–2806.

J. Kang et al., An Ag-grid/graphene hybrid structure for large-scale, transparent, flexible heaters, Nanoscale, 2015, 7(15), p 6567–6573.

T. Qiu et al., Hydrogen reduced graphene oxide/metal grid hybrid film: towards high performance transparent conductive electrode for flexible electrochromic devices, Carbon, 2015, 81, p 232–238.

T. He et al., A tough and high-performance transparent electrode from a scalable and transfer-free method, ACS Nano, 2014, 8(5), p 4782–4789.

L. Zhou et al., Screen-printed poly (3, 4-ethylenedioxythiophene): poly (styrenesulfonate) grids as ITO-free anodes for flexible organic light-emitting diodes, Adv. Func. Mater., 2018, 28(11), p 1705955.

S. Bai et al., Laser-assisted reduction of highly conductive circuits based on copper nitrate for flexible printed sensors, Nano-micro Lett., 2017, 9(4), p 1–13.

W. Zhao et al., Flexible transparent supercapacitors: materials and devices, Adv. Func. Mater., 2020, 31(11), p 2009136.

C. Zhang et al., Thin-metal-film-based transparent conductors: material preparation, optical design, and device applications, Adv. Opt. Mater., 2021, 9(3), p 40.

T. Araki et al., Low haze transparent electrodes and highly conducting air dried films with ultra-long silver nanowires synthesized by one-step polyol method, Nano Res., 2014, 7(2), p 236–245.

P.J. King et al., Percolation effects in supercapacitors with thin, Trans. Carbon Nanot. Electrodes. ACS Nano, 2012, 6(2), p 1732–1741.

D. Shin et al., Solution-processed Ag nanowires + PEDOT:PSS hybrid electrode for Cu(In, Ga)Se2 thin-film solar cells, ACS Appl. Mater. Interfaces., 2015, 7(24), p 13557–13563.

J.-L. Chiang et al., Deposition of high-transmittance ITO thin films on polycarbonate substrates for capacitive-touch applications, Vacuum, 2021, 186, 110046.

Y. Han et al., Efficiency above 12% for 1 cm2 flexible organic solar cells with Ag/Cu grid transparent conducting electrode, Adv. Sci., 2019, 6(22), p 1901490.

L. Chang et al., Ionogel/Copper grid composites for high-performance, ultra-stable flexible transparent electrodes, ACS Appl. Mater. Interf., 2018, 10(34), p 29010–29018.

D.W. Kim et al., Material aspects of triboelectric energy generation and sensors, NPG Asia Mater., 2020, 12(1), p 6.

Z.L. Wang, On Maxwell’s displacement current for energy and sensors: the origin of nanogenerators, Mater. Today, 2017, 20(2), p 74–82.

M. Shaker, E. Salahinejad and F. Ashtari-Mahini, Hydrophobization of metallic surfaces by means of Al2O3-HDTMS coatings, Appl. Surf. Sci., 2018, 428, p 455–462.

M. Shaker and E. Salahinejad, A combined criterion of surface free energy and roughness to predict the wettability of non-ideal low-energy surfaces, Prog. Org. Coat., 2018, 119, p 123–126.

Acknowledgments

The research was supported by the National Nature Science Foundation of China (Grant No. 61874015), the National Key Research and Development Program of China (Grant No. 2018YFC0117202), the Natural Science Foundation of Chongqing (2022NSCQ-BHX5234), and the Chongqing Venture & Innovation Support Program for Chongqing Overseas Returnees (No. CX2019031).

Author information

Authors and Affiliations

Contributions

WC and HY initiated the study, proposed the approach of the research and supervised the research. HY and WL provided theory consultant. WC prepared the nanogenerator including design, fabrication, Characterization and then simulated and analyzed the research. MS prepared the manuscript and helped with the results analysis. All authors revised the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, W., Shaker, M., Lei, W. et al. A Highly Transparent Self-Powered Touch Sensor Based on Hierarchical (Micro-Nano) Cu Grid on Polyethylene Terephthalate Composite Electrodes for Smart Wear. J. of Materi Eng and Perform 33, 362–371 (2024). https://doi.org/10.1007/s11665-023-07967-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07967-6