Abstract

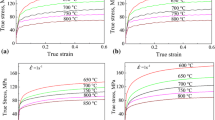

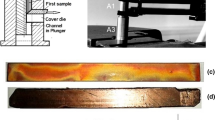

This study researched how Ce addition affects the microstructure and mechanical behavior of Cu-Fe-Ti-Mg alloys during hot compression. A thermal deformation simulation machine was used to study the hot compression process at 0.001-10 s−1 strain rates and 500-950 °C deformation temperatures. The true stress–strain curves and constitutive equations were obtained for the two alloys. Based on the electron backscatter diffraction analysis, the addition of Ce can improve the dislocation density and texture strength of the Cu-Fe-Ti-Mg alloy. The microstructure and precipitates of the Cu-Fe-Ti-Mg-Ce alloy were also analyzed. The average grain size of the Cu-Fe-Ti-Mg-Ce alloy is smaller than the Cu-Fe-Ti-Mg alloy. The addition of Ce delayed dynamic recrystallization. These findings provide a theoretical foundation for understanding the Ce addition effects on the hot deformation behavior of the Cu-Fe-Ti-Mg alloy, serving as a reference for industrial manufacturing of the alloy.

Similar content being viewed by others

References

X.H. Zhang, Y. Zhang, B.H. Tian, K.X. Song, P. Liu, Y.L. Jia, X.H. Chen, J.C. An, Z. Zhao, and Y. Liu, Review of Nano-phase Effects in High Strength and Conductivity Copper Alloys, Nanotechnol. Rev., 2019, 8, p 383–395.

H.Y. Yang, K.Q. Li, Y.Q. Bu, J.M. Wu, Y.T. Fang, L. Meng, J.B. Liu, and H.T. Wang, Nanoprecipitates Induced Dislocation Pinning and Multiplication Strategy for Designing High Strength, Plasticity and Conductivity Cu Alloys, Scripta Mater., 2021, 195, p 113741.

Z.L. Zhao, Z. Xiao, Z. Li, W.T. Qiu, H.Y. Jiang, Q. Lei, Z.R. Liu, Y.B. Jiang, and S.J. Zhang, Microstructure and Properties of a Cu-Ni-Si-Co-Cr Alloy with High Strength and High Conductivity, Mater. Sci. Eng. A, 2019, 759, p 396–403.

X.H. Zhang, Y. Zhang, B.H. Tian, Y.L. Jia, Y. Liu, and K.X. Song, Cr effects on the Electrical Contact Properties of the Al2O3-Cu/15W Composites, Nanotechnol. Rev., 2019, 8, p 128–135.

K.X. Song, Y.F. Geng, Y.J. Ban, Y. Zhang, Z. Li, X.J. Mi, J. Cao, Y.J. Zhou, and X.B. Zhang, Effects of Strain Rates on Dynamic Deformation Behavior of Cu-20Ag Alloy, J. Mater. Sci. Technol., 2021, 79, p 75–87.

I. Batra, G. Dey, U. Kulkarni, and S. Banerjee, Precipitation in a Cu-Cr-Zr Alloy, Mater. Sci. Eng. A, 2003, 356, p 32–36.

A. Chbihi, X. Sauvage, and D. Blavette, Atomic Scale Investigation of Cr Precipitation in Copper, Acta Mater., 2012, 60, p 4575–4585.

G. Yang, Z. Li, Y. Yuan, and Q. Lei, Microstructure, Mechanical Properties and Electrical Conductivity of Cu-0.3 Mg-0.05 Ce Alloy Processed by Equal Channel Angular Pressing and Subsequent Annealing, J. Alloys Compd., 2015, 640, p 347–354.

C.D. Xia, Y.L. Jia, W. Zhang, K. Zhang, Q.Y. Dong, G.Y. Xu, and M.P. Wang, Study of Deformation and Aging Behaviors of a Hot Rolled–Quenched Cu-Cr-Zr-Mg-Si Alloy during Thermomechanical Treatments, Mater. Des., 2012, 39, p 404–409.

G.D. Shi, X.H. Chen, H. Jiang, Z.D. Wang, H. Tang, and Y.Q. Fan, Strengthening Mechanisms of Fe Nanoparticles for Single Crystal Cu-Fe Alloy, Mater. Sci. Eng. A, 2015, 636, p 43–47.

D.P. Lu, J. Wang, W.J. Zeng, Y. Liu, L. Lu, and B.D. Sun, Study on High-Strength and High-Conductivity Cu-Fe-P Alloys, Mater. Sci. Eng. A, 2006, 421, p 254–259.

B.J. Wang, Y. Zhang, B.H. Tian, V. Yakubov, J.C. An, A.A. Volinsky, Y. Liu, K.X. Song, L.H. Li, and M. Fu, Effects of Ce and Y Addition on Microstructure Evolution and Precipitation of Cu-Mg alloy Hot Deformation, J. Alloy. Compd., 2019, 781, p 118–130.

L. Zhang, Z. Li, Q. Lei, W.T. Qiu, and H.T. Luo, Hot Deformation Behavior of Cu-8.0 Ni-1.8 Si–0.15 Mg Alloy, Mater. Sci. Eng. A, 2011, 528, p 1641–1647.

H. Zhang, H.G. Zhang, and L.X. Li, Hot Deformation Behavior of Cu-Fe-P Alloys during Compression at Elevated Temperatures, J. Mater. Process. Technol., 2009, 209, p 2892–2896.

C. Zhao, Z. Wang, D.X. Li, D.Q. Pan, B.M. Lou, Z.Q. Luo, and W.W. Zhang, Optimization of Strength and Ductility in an As-Extruded Cu-15Ni-8Sn Alloy by the Additions of Si and Ti, J. Alloy. Compd., 2020, 823, p 153759.

Y.J. Ban, Y. Zhang, Y.L. Jia, B.H. Tian, and X. Li, Effects of Cr Addition on the Constitutive Equation and Precipitated Phases of Copper Alloy during Hot Deformation, Mater. Des., 2020, 191, p 108613.

Y.F. Geng, X. Li, H.L. Zhou, Y. Zhang, Y.L. Jia, B.H. Tian, Y. Liu, A.A. Volinsky, X.H. Zhang, and K.X. Song, Effect of Ti Addition on Microstructure Evolution and Precipitation in Cu-Co-Si Alloy during Hot Deformation, J. Alloy. Compd., 2020, 821, p 153518.

P.H. Geng, G.L. Qin, J. Zhou, T.Y. Li, and N.S. Ma, Characterization of Microstructures and Hot-Compressive Behavior of GH4169 Superalloy by Kinetics Analysis and Simulation, J. Mater. Process. Technol., 2021, 288, p 116879.

P.F. Yang, M. Zhou, Y. Zhang, Y.L. Jia, B.H. Tian, Y. Liu, X. Li, and A.A. Volinsky, Effect of Y Addition on Microstructure Evolution and Precipitation of Cu-Co-Si Alloy during Hot Deformation, Mater. Charact., 2021, 181, p 111502.

K.M. Liu, Z.Y. Jiang, H.T. Zhou, D.P. Lu, A. Atrens, and Y.L. Yang, Effect of Heat Treatment on the Microstructure and Properties of Deformation-Processed Cu-7Cr In Situ Composites, J. Mater. Eng. Perform., 2015, 24, p 4340–4345.

C. Roucoules, M. Pietrzyk, and P. Hodgson, Analysis of Work Hardening and Recrystallization during the Hot Working of Steel Using a Statistically Based Internal Variable Model, Mater. Sci. Eng. A, 2003, 339, p 1–9.

Y.Q. Ning, X. Luo, H.Q. Liang, H.Z. Guo, J.L. Zhang, and K. Tan, Competition between Dynamic Recovery and Recrystallization during Hot Deformation for TC18 Titanium Alloy, Mater. Sci. Eng. A, 2015, 635, p 77–85.

Z.Y. Ding, S.G. Jia, P.F. Zhao, M. Deng, and K.X. Song, Hot Deformation Behavior of Cu-0.6 Cr-0.03 Zr Alloy during Compression at Elevated Temperatures, Mater. Sci. Eng. A, 2013, 570, p 87–91.

G.L. Ji, G. Yang, L. Li, and Q. Li, Modeling Constitutive Relationship of Cu-0.4 Mg Alloy during Hot Deformation, J. Mater. Eng. Perform., 2014, 23, p 1770–1779.

W.L. Cheng, Y. Bai, S.C. Ma, L.F. Wang, H.X. Wang, and H. Yu, Hot Deformation Behavior and Workability Characteristic of a Fine-Grained Mg-8Sn-2Zn-2Al Alloy with Processing Map, J. Mater. Sci. Technol., 2019, 35, p 1198–1209.

N. Tahreen, D.F. Zhang, F.S. Pan, X.Q. Jiang, D.Y. Li, and D.L. Chen, Hot Deformation and Processing Map of an As-Extruded Mg-Zn-Mn-Y Alloy Containing I and W Phases, Mater. Des., 2015, 87, p 245–255.

X. Wang, L.I. Zhou, Z. Xiao, and W.T. Qiu, Microstructure Evolution and Hot Deformation Behavior of Cu-3Ti-0.1Zr Alloy with Ultra-high Strength, Trans. Nonferrous Met. Soc. China, 2020, 30, p 2737–2748.

Y.F. Geng, Y. Zhang, K.X. Song, Y.L. Jia, X. Li, H.R. Stock, H.L. Zhou, B.H. Tian, Y. Liu, and A.A. Volinsky, Effect of Ce Addition on Microstructure Evolution and Precipitation in Cu-Co-Si-Ti Alloy during Hot Deformation, J. Alloy. Compd., 2020, 842, p 155666.

X.R. Chen, Q.Y. Liao, Y.X. Niu, W.T. Jia, Q.C. Le, C.L. Cheng, F.X. Yu, and J.Z. Cui, A Constitutive Relation of AZ80 Magnesium Alloy during Hot Deformation Based on Arrhenius and Johnson–Cook Model, J. Mater. Res. Technol., 2019, 8, p 1859–1869.

A. Galiyev, R. Kaibyshev, and G. Gottstein, Correlation of Plastic Deformation and Dynamic Recrystallization in Magnesium Alloy ZK60, Acta Mater., 2001, 49, p 1199–1207.

Y.H. Duan, L.S. Ma, H.R. Qi, R.Y. Li, and P. Li, Developed Constitutive Models, Processing Maps and Microstructural Evolution of Pb-Mg-10Al-0.5 B Alloy, Mater. Charact., 2017, 129, p 353–366.

H. Mirzadeh, J.M. Cabrera, and A. Najafizadeh, Modeling and Prediction of Hot Deformation Flow Curves, Metall. Mater. Trans. A., 2012, 43, p 108–123.

S. Satheesh Kumar, T. Raghu, P.P. Bhattacharjee, G.A. Rao, and U. Borah, Constitutive Modeling for Predicting Peak Stress Characteristics during Hot Deformation of Hot Isostatically Processed Nickel-Base Superalloy, J. Mater. Sci., 2015, 50, p 6444–6456.

Y.F. Geng, Y.J. Ban, B.J. Wang, X. Li, K.X. Song, Y. Zhang, Y.L. Jia, B.H. Tian, Y. Liu, and A.A. Volinsky, A Review of Microstructure and Texture Evolution with Nanoscale Precipitates for Copper Alloys, J. Mater. Res. Technol., 2020, 9, p 11918–11934.

L. Blaz, E. Evangelista, and M. Niewczas, Precipitation Effects during Hot Deformation of a Copper Alloy, Metall. Mater. Trans. A., 1994, 25, p 257–266.

Y. Zhang, H.L. Sun, A.A. Volinsky, B.H. Tian, K.X. Song, B.J. Wang, and Y. Liu, Hot Workability and Constitutive Model of the Cu-Zr-Nd Alloy, Vacuum, 2017, 146, p 35–43.

R. Mishnev, I. Shakhova, A. Belyakov, and R. Kaibyshev, Deformation Microstructures, Strengthening Mechanisms, and Electrical Conductivity in a Cu-Cr-Zr alloy, Mater. Sci. Eng. A, 2015, 629, p 29–40.

F. Bittner, S. Yin, A. Kauffmann, J. Freudenberger, H. Klauß, G. Korpala, R. Kawalla, W. Schillinger, and L. Schultz, Dynamic Recrystallization and Precipitation Behaviour of High Strength and Highly Conducting Cu-Ag-Zr-Alloys, Mater. Sci. Eng. A, 2014, 597, p 139–147.

A.S.H. Kabir, M. Sanjari, J. Su, I.H. Jung, and S. Yue, Effect of Strain-Induced Precipitation on Dynamic Recrystallization in Mg-Al-Sn Alloys, Mater. Sci. Eng. A, 2014, 616, p 252–259.

Y.S. Wu, X.Z. Qin, C.S. Wang, and L.Z. Zhou, Influence of Phosphorus on Hot Deformation Microstructure of a Ni-Fe-Cr Based Alloy, Mater. Sci. Eng. A, 2019, 768, p 138454.

Y.S. Wu, Z. Liu, X.Z. Qin, C.S. Wang, and L.Z. Zhou, Effect of Initial State on Hot Deformation and Dynamic Recrystallization of Ni-Fe Based Alloy GH984G for Steam Boiler Applications, J. Alloy. Compd., 2019, 795, p 370–384.

C.S. Wang, H.D. Fu, and J.X. Xie, Dynamic Recrystallization Behavior and Microstructure Evolution of High-Performance Cu-3.28Ni-0.6Si-0.22Zn-0.11Cr-0.04P during Hot Compression, Rare Met., 2021, 40, p 156–167.

C. Haase and L.A. Barrales-Mora, Influence of Deformation and Annealing Twinning on the Microstructure and Texture Evolution of Face-Centered Cubic High-Entropy Alloys, Acta Mater., 2018, 150, p 88–103.

M.Y. Li, H. Wang, Y.H. Guo, H.L. Wang, D.D. Zheng, J.F. Shan, and Y.Q. Chang, Microstructures and Mechanical Properties of the nOvel CuCrZrFeTiY Alloy for Fusion Reactor, J. Nucl. Mater., 2020, 532, p 152063.

J. Yi, Y.L. Jia, Y.Y. Zhao, Z. Xiao, K.J. He, Q. Wang, M.P. Wang, and Z. Li, Precipitation Behavior of Cu-3.0Ni-0.72Si Alloy, Acta Mater., 2019, 166, p 261–270.

H.Y. Yang, Y.Q. Bu, J.M. Wu, Y.T. Fang, J.B. Liu, L.Y. Huang, and H.T. Wang, High Strength, High Conductivity and Good Softening Resistance Cu-Fe-Ti Alloy, J. Alloy. Compd., 2022, 925, p 166595.

C. Wang, Y.T. Liu, T. Lin, T.J. Luo, Y.H. Zhao, H. Hou, and Y.S. Yang, Hot Compression Deformation Behavior of Mg-5Zn-3.5Sn-1Mn-0.5Ca-0.5Cu Alloy, Mater. Charact., 2019, 157, p 109896.

D. Jia, W.R. Sun, D.S. Xu, and F. Liu, Dynamic Recrystallization Behavior of GH4169G Alloy during Hot Compressive Deformation, J. Mater. Sci. Technol., 2019, 35, p 1851–1859.

D.Q. Zhou, X.Q. Xu, H.H. Mao, Y.F. Yan, T.G. Nieh, and Z.P. Lu, Plastic Flow Behaviour in an Alumina-Forming Austenitic Stainless Steel at Elevated Temperatures, Mater. Sci. Eng. A, 2014, 594, p 246–252.

W.C. Xu, X.Z. Jin, W.D. Xiong, X.Q. Zeng, and D.B. Shan, Study on Hot Deformation Behavior and Workability of Squeeze-Cast 20 vol.% SiCw/6061Al Composites Using Processing Map, Mater. Charact., 2018, 135, p 154–166.

Y. Li and T.G. Langdon, Creep Behavior of an Al-6061 Metal Matrix Composite Reinforced with Alumina Particulates, Acta Mater., 1997, 45, p 4797–4806.

S.J. Zhu, L.M. Peng, Z.Y. Ma, J. Bi, F.G. Wang, and Z.G. Wang, High Temperature Creep Behavior of SiC Whisker-Reinforced Al-Fe-V-Si Composite, Mater. Sci. Eng. A, 1996, 215, p 120–124.

A. Sarkar, M. Prasad, and S.N. Murty, Effect of Initial Grain Size on Hot Deformation Behaviour of Cu-Cr-Zr-Ti Alloy, Mater. Charact., 2020, 160, p 110112.

W. Wang, E.Y. Guo, Z.N. Chen, H.J. Kang, Z.J. Chen, C.L. Zou, R.G. Li, G.M. Yin, and T.M. Wang, Correlation between Microstructures and Mechanical Properties of Cryorolled CuNiSi Alloys with Cr and Zr Alloying, Mater. Charact., 2018, 144, p 532–546.

Acknowledgments

This research was supported by the National Natural Science Foundation of China (52071134), the Program for Innovative Research Team at the University of Henan Province (22IRTSTHN001), China Postdoctoral Science Foundation (2020M682316, 2021T140779), and Outstanding Talents Innovation Fund of the Henan Province (ZYQR201912164).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that might influence the work described herein.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, Q., Zhou, M., Zhang, Y. et al. Ce Effects on Dynamic Recrystallization of Cu-Fe-Ti-Mg Alloys Due to Hot Compression. J. of Materi Eng and Perform 32, 9698–9710 (2023). https://doi.org/10.1007/s11665-023-07810-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07810-y