Abstract

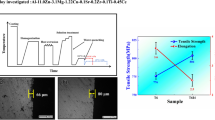

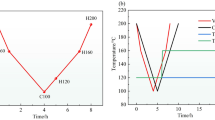

This study aims to investigate the microstructure and properties of Al-Zn-Mg-Cu alloy that is subjected to a coupled aging treatment, interrupted aging (T6I4) and retrogression and re-aging (RRA). For this purpose, the properties were systematically investigated through the tests of Vickers hardness, tension, and intergranular corrosion. The matrix precipitates were analyzed by transmission electron microscopy. According to the experimental results, the alloy treated by T6I4-RRA was improved by 37% in elongation with the loss of 2% in strength compared to that treated by peak aging (T6). In addition, the corrosion depth of the alloy treated by coupled aging decreased by 40% compared to that of the T6-aged material. According to the microstructure investigations, finer precipitates were formed in the T6I4-RRA-aged alloy, accompanied with intermittent grain boundary precipitates and appropriate precipitate-free zones. Importantly, this peculiar microstructure contributes to resolving the contradiction between strength properties and corrosion resistance of Al-Zn-Mg-Cu alloy.

Similar content being viewed by others

References

K. Wen et al., Transformation and Dissolution of Second Phases During Solution Treatment of an Al-Zn-Mg-Cu Alloy Containing High Zinc, Rare Met., 2018, 37(5), p 376–380. https://doi.org/10.1007/s12598-016-0768-6

T. Dursun and S. Costas, Recent Developments in Advanced Aircraft Aluminium Alloys, Mater. Des., 2014, 56, p 862–871. https://doi.org/10.1016/j.matdes.2013.12.002

Y. Hou et al., Effects of Artificial Aging on Microstructure, Mechanical Properties and Stress Corrosion Cracking of a Novel High Strength 7A99 Al Alloy, Mater. Sci. Eng. A, 2020, 780, p 139217. https://doi.org/10.1016/j.msea.2020.139217

P. Liu et al., Effect of Aging Treatment on Microstructure and Corrosion Behavior of Al-Zn-Mg Aluminum Alloy in Aqueous Solutions with Different Aggressive Ions, J. Mater. Sci. Technol., 2021, 64, p 85–98. https://doi.org/10.1016/j.jmst.2019.09.030

Cina, B. Reducing the susceptibility of alloys, particularly aluminium alloys, to stress corrosion cracking. US, US3856584 A. 1974. https://www.freepatentsonline.com/3856584.html

S. Chen et al. Effect of Heat Treatment on Strength, Exfoliation Corrosion and Electrochemical Behavior of 7085 Aluminum Alloy, Mater. Des., 2012, 35, p 93–98. https://doi.org/10.1016/j.matdes.2011.09.033

R.N. Lumley, I.J. Polmear, and A.J. Morton, Development of Mechanical Properties During Secondary Aging in Aluminium Alloys, Mater. Sci. Technol., 2005, 21(9), p 1025–1032. https://doi.org/10.1179/174328405x51875

J. Buha et al. Secondary Precipitation in an Al–Mg–Si–Cu Alloy, Acta Mater., 2007, 55(9), p 3015–3024. https://doi.org/10.1016/j.actamat.2007.01.006

R.K.W. Marceau et al. Evolution of Solute Clustering in Al–Cu–Mg Alloys During Secondary Ageing, Acta Mater., 2010, 58(5), p 1795–1805. https://doi.org/10.1016/j.actamat.2009.11.021

J.-F. Li et al. Mechanical Properties, Corrosion Behaviors and Microstructures of 7075 Aluminium Alloy with Various Aging Treatments, Trans. Nonferrous Met. Soc. China, 2008, 18(4), p 755–762. https://doi.org/10.1016/S1003-6326(08)60130-2

A.L.M. Carvalho et al. Microstructure Analysis of 7050 Aluminum Alloy Processed by Multistage Aging Treatments, J. Alloys Compd., 2022, 907, 164400. https://doi.org/10.1016/j.jallcom.2022.164400

L. Qu et al. Influence of Aging Treatment on the Microstructure, Mechanical Properties and Corrosion Behavior of Al-Zn-Mg-Sc-Zr Alloy, Vacuum, 2022, 200, p 110995. https://doi.org/10.1016/j.vacuum.2022.110995

W. Yang et al. Investigation of Mechanical and Corrosion Properties of an Al-Zn-Mg-Cu Alloy Under Various Ageing Conditions and Interface Analysis of η′ Precipitate, Mater. Des., 2015, 85, p 752–761. https://doi.org/10.1016/j.matdes.2015.06.183

X. Xu, P. Zhang, R. Zhang et al. Effect of Multi-stage Solution on Microstructure and Properties of Al–10.5Zn–2.05Mg–1.02Cu–0.2Zr–0.923Ti Alloy Extrusion, Appl. Phys. A, 2020, 126, p 679. https://doi.org/10.1007/s00339-020-03868-w

P. Dai et al. Nano-scale Precipitate Evolution and Mechanical Properties of 7085 Aluminum Alloy During Thermal Exposure, Mater. Sci. Eng. A, 2018, 729, p 411–422. https://doi.org/10.1016/j.msea.2018.05.092

W. Yang et al. Precipitation Behaviour of Al-Zn-Mg-Cu Alloy and Diffraction Analysis from η′ Precipitates in Four Variants, J. Alloys Compd., 2014, 610, p 623–629. https://doi.org/10.1016/j.jallcom.2014.05.061

L.K. Berg et al. GP-Zones in Al–Zn–Mg Alloys and their Role in Artificial Aging, Acta Mater., 2001, 49(17), p 3443–3451. https://doi.org/10.1016/S1359-6454(01)00251-8

M. Dumont et al. Characterisation of the Composition and Volume Fraction of η′ and η Precipitates in an Al–Zn–Mg Alloy by a Combination of Atom Probe, Small-Angle X-ray Scattering and Transmission Electron Microscopy, Acta Mater., 2005, 53(10), p 2881–2892. https://doi.org/10.1016/j.actamat.2005.03.004

Y. Fan et al. Comparisons of Age Hardening and Precipitation Behavior in 7075 Alloy Under Single and Double-Stage Aging Treatments, Met. Mater. Int., 2021, 27(10), p 4204–4215. https://doi.org/10.1007/s12540-020-00875-7

K. Osamura, Precipitation Behavior and Change of Yield Strength During Artificial Aging Al-Zn-Mg-Cu Alloys, Light Metals, 1984, 34, p 517–524.

T. Aoba, K. Masakazu and M. Hiromi, Effects of Aging on Mechanical Properties and Microstructure of Multi-directionally Forged 7075 Aluminum Alloy, Mater. Sci. Eng. A, 2017, 700, p 220–225. https://doi.org/10.1016/j.msea.2017.06.017

A.L.M. Carvalho et al. Microstructure Analysis of 7050 Aluminum Alloy Processed by Multistage Aging Treatments, J. Alloy. Compd., 2022, 907, p 164400. https://doi.org/10.1016/j.jallcom.2022.164400

Y. Zou et al. Effect of Ageing Temperature on Microstructure, Mechanical Property and Corrosion Behavior of Aluminum Alloy 7085, J. Alloys Compd., 2020, 823, p 1537. https://doi.org/10.1016/j.jallcom.2020.153792

S.C. Jacumasso et al. Microstructural Characterization of Interrupted Aging on an AA7050 Aluminum Alloy, Mater. Charact., 2019, 152, p 180–187. https://doi.org/10.1016/j.matchar.2019.04.013

J. Buha, R.N. Lumley and A.G. Crosky, Secondary Ageing in an Aluminium Alloy 7050, Mater. Sci. Eng. A, 2008, 492(1–2), p 1–10. https://doi.org/10.1016/j.msea.2008.02.039

A.K. Vasudevan and R.D. Doherty, Grain Boundary Ductile Fracture in Precipitation Hardened Aluminum Alloys, Acta Metall., 1987, 35(6), p 1193–1219. https://doi.org/10.1016/0001-6160(87)90001-0

J. Wloka, T. Hack and S. Virtanen, Influence of Temper and Surface Condition on the Exfoliation Behaviour of High Strength Al-Zn-Mg-Cu Alloys, Corros. Sci., 2007, 49(3), p 1437–1449. https://doi.org/10.1016/j.corsci.2006.06.033

S.-Y. Chen et al. Effect of Heat Treatment on Stress Corrosion Cracking, Fracture Toughness and Strength of 7085 Aluminum Alloy, Trans. Nonferrous Met. Soc. China, 2014, 24(7), p 2320–2325. https://doi.org/10.1016/S1003-6326

Y. Wang et al., Effect of Retrogression Treatments on Microstructure, Hardness and Corrosion Behaviors of Aluminum Alloy 7085, J. Alloys Compd., 2020, 814, p 152264. https://doi.org/10.1016/j.jallcom.2019.152264

Y. Deng et al., Effects of Sc and Zr Microalloying Additions and Aging Time at 120 C on the Corrosion Behaviour of an Al–Zn–Mg Alloy, Corros. Sci., 2012, 65, p 288–298. https://doi.org/10.1016/j.corsci.2012.08.024

J. Zuo et al., Effect of Deformation Induced Precipitation on Dynamic Aging Process and Improvement of Mechanical/Corrosion Properties AA7055 Aluminum Alloy, J. Alloys Compd., 2017, 708, p 1131–1140. https://doi.org/10.1016/j.jallcom.2017.03.091

L. Li et al., Study on the Optimizing Mechanisms of Superior Comprehensive Properties of a Hot Spray Formed Al-Zn-Mg-Cu Alloy, Mater. Sci. Eng. A, 2019, 742, p 102–108. https://doi.org/10.1016/j.msea.2018.10.120

P. Xie et al., Enhancing the Stress Corrosion Cracking Resistance of a Low-Cu Containing Al-Zn-Mg-Cu Aluminum Alloy by Step-Quench and Aging Heat Treatment, Corros. Sci., 2019, 161, p 1081. https://doi.org/10.1016/j.corsci.2019.108184

Y. Luo et al., Effects of Cu and Ti Contents on Microstructure and Properties of Al-88 Zn-22 Mg-xCu-02 Zr-01 Sr-yTi Aluminum Alloy, J. Mater. Eng. Perform., 2022, 31, p 4495–4506. https://doi.org/10.1007/s11665-021-06567-6

Y. Luo et al., Microstructure and Properties of T6I4 Aged 700-MPa-Grade Aluminum Alloy, J. Mater. Eng. Perform., 2022 https://doi.org/10.1007/s11665-022-06999-8

Acknowledgments

The authors gratefully recognize the Equipment Pre-research Foundation of the 13th Five-Year Plan, Ministry of Development, Key Project No. 6140922010201 of the Central Military Commission of China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wei, T., Chen, R., Xu, X. et al. Effect of Interrupted Aging–Retrogression Re-Aging Treatment on the Microstructure and Properties of Al-Zn-Mg-Cu Alloy. J. of Materi Eng and Perform 32, 6630–6641 (2023). https://doi.org/10.1007/s11665-022-07592-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07592-9