Abstract

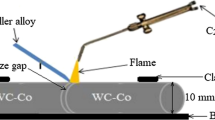

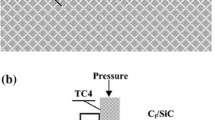

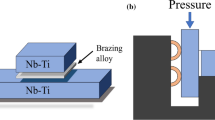

This study has focused on the influence of size and content of SiC particle incorporation on the wetting behavior of the Ticusil brazing filler alloy and on its brazing performance in C/SiC composite/Ti6Al4V alloy joints. The effect of the size and content of additive SiC particles on the variation of molten brazing filler alloy contact angle was recorded at various brazing time and temperatures. Moreover, the microstructural evolution and mechanical properties of the additive containing C/SiC composite/Ti6Al4V alloy joints produced by the brazing method were investigated. The contact angles in both brazing filler alloys containing nano- and micro-sized SiC particles exhibited a sudden decrease with time during isothermal holding as observed in as-received brazing filler alloys. As the quantity of the SiC particles increased in the brazing alloy, the recorded contact angle values including the final, stable contact angle increased, while the time for the drastic contact angle change also increased remarkably. Compared to as-received counterparts, the addition of 2 wt.% nano-sized SiC and 1 wt.% micro-sized SiC particles improved the shear strength of the joints by 35 and 8%, respectively. Although the recorded contact angle values were close to each other in brazing alloys containing SiC particles with different sizes (37 and 42° for 1 wt.% micro-sized and 2 wt.% nano-sized additions), higher increment was achieved in the mechanical performance of the joints with nano-sized SiC additive due to more homogeneous reinforcement effect of the nanoparticles. The results indicated that the optimum brazing filler alloy contact angle for the highest shear strength is ∼ 40° for both nano- and micron-sized additive containing Ticusil filler alloy.

Similar content being viewed by others

References

W. Krenkel and F. Berndt, C/C-SiC Composites for Space Applications and Advanced Friction Systems, Mater. Sci. Eng. A, 2005, 412(1–2), p 177–181. https://doi.org/10.1016/j.msea.2005.08.204

S. Tülbez, Z. Esen, and A.F. Dericioglu, Effect of CNT Impregnation on the Mechanical and Thermal Properties of C/C-SiC Composites, Adv. Compos. Hybrid Mater., 2020, 3, p 177–186. https://doi.org/10.1007/s42114-020-00155-3

S.Tülbez, Processing and Characterization of Carbon Fiber Reinforced Silicon Carbide (C/C-SiC) Matrix Composites. Master Thesis. Middle East Technical University, 2015

P. Singh, H. Pungotra, and N.S. Kalsi, On the Characteristics of Titanium Alloys for the Aircraft Applications, Mater. Today Proc., 2017, 4(8), p 8971–8982. https://doi.org/10.1016/j.matpr.2017.07.249

S. Mishra, A. Sharma, D.H. Jung, and J.P. Jung, Recent Advances in Active Metal Brazing of Ceramics and Process, Met. Mater. Int., 2020, 26(8), p 1087–1098. https://doi.org/10.1007/s12540-019-00536-4

J.H. Xiong, J.H. Huang, H. Zhang, and X.K. Zhao, Brazing of Carbon Fiber Reinforced SiC Composite and TC4 Using Ag-Cu-Ti Active Brazing Alloy, Mater. Sci. Eng. A, 2010, 527(4–5), p 1096–1101. https://doi.org/10.1016/j.msea.2009.09.024

S. Metco, An Introduction to Brazing Fundamentals , Materials , Processing, 4, 2014

R. Asthana and M. Singh, Active metal brazing of advanced ceramic composites to metallic systems. Woodhead Publishing Limited, 2013

P.Roberts, Introduction to Brazing Technology (2016)

X. Dai, J. Cao, Z. Chen, X. Song, and J. Feng, Brazing SiC Ceramic Using Novel B4C Reinforced Ag-Cu-Ti Composite Filler, Ceram. Int., 2016, 42(5), p 6319–6328. https://doi.org/10.1016/j.ceramint.2016.01.021

W. Hanson, Joining of Ceramics Using a Ceramic-Modified Braze Alloy, Mater. Technol., 1999, 12(2), p 53–56. https://doi.org/10.1080/10667857.1999.11752814

J. Xiong, J. Huang, Z. Wang, G. Lin, H. Zhang, and X. Zhao, Joining of Cf/SiC Composite to Ti Alloy Using Composite Filler Materials, Mater. Sci. Technol., 2009, 25(8), p 1046–1050. https://doi.org/10.1179/174328408X378889

J.H. Xiong, J.H. Huang, H.Y. Xue, H. Zhang, X.K. Zhao, and G.B. Lin, Joining of Cf/SiC Composite to Ti Alloy Using AgCuTi-W Composite Filler Materials, Hangkong Cailiao Xuebao J. Aeronaut. Mater., 2009, 29(6), p 48–52. https://doi.org/10.3969/j.issn.1005-5053.2009.6.010

Y.M. He, J. Zhang, C.F. Liu, and Y. Sun, Microstructure and Mechanical Properties of Si3N4/Si3N4 Joint Brazed with Ag-Cu-Ti + SiCp Composite Filler, Mater. Sci. Eng. A, 2010, 527(12), p 2819–2825. https://doi.org/10.1016/j.msea.2010.01.065

W. Wang, D. Fan, J. Huang, C. Li, J. Yang, and S. Chen, Microstructural Mechanism and Mechanical Properties of Cf/SiC Composite/TC4 Alloy Joints Composite-Diffusion Brazed with TiZrCuNi + TiCp Composite Filler, Mater. Sci. Eng. A, 2018, 728, p 1–9. https://doi.org/10.1016/j.msea.2018.04.091

X.R. Song, H.J. Li, and X. Zeng, Brazing of C/C Composites to Ti6Al4V Using Multiwall Carbon Nanotubes Reinforced TiCuZrNi Brazing Alloy, J. Alloys Compd., 2016, 664, p 175–180. https://doi.org/10.1016/j.jallcom.2015.12.242

G. Lin, J. Huang, H. Zhang, and X. Zhao, Joints of Cf/SiC Composite to Ti-Alloy with In-Situ Synthesized TiC x Improved Brazing Layers, Mater. Trans., 2006, 47(4), p 1261–1263. https://doi.org/10.2320/matertrans.47.1261

G.B. Lin and J.H. Huang, Brazed Joints of Cf-SiC Composite to Ti Alloy Using Ag-Cu-Ti-(Ti+C) Mixed Powder as Interlayer, Powder Metall., 2006, 49(4), p 345–348. https://doi.org/10.1179/174329006X113454

D. Liu, K. Zhao, Y. Song, L. Zhang, X. Song, and W. Long, Effect of Introducing Carbon Fiber into AgCuTi Filler on Interfacial Microstructure and Mechanical Property of C/C-TC4 Brazed Joints, Mater. Charact., 2019, 157, p 109890. https://doi.org/10.1016/j.matchar.2019.109890

Z. Fan, M. Guo, W. Fu, Y. Xue, S. Hu, and X. Song, Wettability and Spreading Behavior of Sn-Cr Alloys on SiC, Mater. Chem. Phys., 2021, 272, p 124979. https://doi.org/10.1016/j.matchemphys.2021.124979

D. Giuranno et al., Design of Refractory SiC/ZrSi2 Composites: Wettability and Spreading Behavior of Liquid Si-10Zr Alloy in Contact with SiC at High Temperatures, J. Eur. Ceram. Soc., 2020, 40(4), p 953–960. https://doi.org/10.1016/j.jeurceramsoc.2019.12.027

J. Yang, J. Huang, Z. Ye, S. Chen, R. Ji, and Y. Zhao, Influence of Interfacial Reaction on Reactive Wettability of Molten Ag-Cu-X wt.%Ti Filler Metal on SiC Ceramic Substrate and Mechanism Analysis, Appl. Surf. Sci., 2018, 436, p 768–778. https://doi.org/10.1016/j.apsusc.2017.12.106

M. Nomura, T. Ichimori, C. Iwamoto, and S.I. Tanaka, Structure of Wetting Front in the Ag-Cu-Ti/SiC Reactive System, J. Mater. Sci., 2000, 35, p 3953–3958. https://doi.org/10.1023/A:1004833914798

X. Song et al., Wetting Behavior and Brazing of Titanium-Coated SiC Ceramics Using Sn0.3Ag0.7Cu Filler, J. Am. Ceram. Soc., 2020, 103(2), p 912–920. https://doi.org/10.1111/jace.16827

R. Asthana, M. Singh, and N. Sobczak, Wetting Behavior and Interfacial Microstructure of Palladium- and Silver-Based Braze Alloys with C-C and SiC-SiC Composites, J. Mater. Sci., 2010, 45(16), p 4276–4290. https://doi.org/10.1007/s10853-010-4647-5

S. Saltik, Z. Esen, and A.F. Dericioglu, Wetting Behavior and Reaction Layer Formation in C/SiC Composite-Titanium Alloy Joints, Adv. Mater. Process. Technol., 2021 https://doi.org/10.1080/2374068x.2021.1971001

H.Y. Lee, A. Sharma, S.H. Kee, Y.W. Lee, J.T. Moon, and J.P. Jung, Effect of Aluminium Additions on Wettability and Intermetallic Compound (IMC) Growth of Lead Free Sn (2 wt.% Ag, 5 wt.% Bi) Soldered Joints, Electron. Mater. Lett., 2014, 10, p 997–1004. https://doi.org/10.1007/s13391-014-3364-7

A. Sharma, B.G. Baek, and J.P. Jung, Influence of La2O3 Nanoparticle Additions on Microstructure, Wetting, and Tensile Characteristics of Sn-Ag-Cu Alloy, Mater. Des., 2015, 87, p 370–379. https://doi.org/10.1016/j.matdes.2015.07.137

A.K. Gain, Y.C. Chan, and W.K.C. Yung, Effect of Additions of ZrO2 Nano-Particles on the Microstructure and Shear Strength of Sn-Ag-Cu Solder on Au/Ni Metallized Cu Pads, Microelectron. Reliab., 2011, 51(12), p 2306–2313. https://doi.org/10.1016/j.microrel.2011.03.042

Y. Wang, W. Wang, J. Huang, S. Zhou, J. Yang, and S. Chen, Composite Brazing of C/C Composite and Ni-Based Superalloy Using (Ag-10Ti) + TiC Filler Material, J. Mater. Process. Technol., 2021, 288, p 116886. https://doi.org/10.1016/j.jmatprotec.2020.116886

A. Sharma, D.E. Xu, and J.P. Jung, Effect of Different Nanoparticles on Microstructure, Wetting and Joint Strength of Al-12Si-20Cu Braze Filler, Mater. Res. Express, 2019, 6, p 056526. https://doi.org/10.1088/2053-1591/ab03e5

N. Eustathopoulos, Wetting by Liquid Metalsapplication in Materials Processing: The Contribution of the Grenoble Group, Metals (Basel), 2015, 5(1), p 350–370. https://doi.org/10.3390/met5010350

B. Cui, J.H. Huang, J.H. Xiong, and H. Zhang, Reaction-Composite Brazing of Carbon Fiber Reinforced SiC Composite and TC4 Alloy Using Ag-Cu-Ti-(Ti+C) Mixed Powder, Mater. Sci. Eng. A, 2013, 562, p 203–210. https://doi.org/10.1016/j.msea.2012.11.031

Y. Mao, L. Peng, Q. Deng, D. Nie, S. Wang, and L. Xi, Wetting Behavior and Interfacial Interactions of Molten Cu50Ti Alloy with Hexagonal BN and TiB2 Ceramics, Ceram. Int., 2016, 42(8), p 9906–9912. https://doi.org/10.1016/j.ceramint.2016.03.090

R. Asthana and M. Singh, Advances in Brazing, Active Metal Brazing of Advanced Ceramic Composites to Metallic Systems, 2013

J. John Williams and J. John, Structure and High-Temperature Properties of Ti5Si3 with Interstitial Additions, 1999 [Online]

M.P. Reddy et al., Enhanced Performance of Nano-Sized SiC Reinforced Al Metal Matrix Nanocomposites Synthesized through Microwave Sintering and Hot Extrusion Techniques, Prog. Nat. Sci. Mater. Int., 2017, 27(5), p 606–614. https://doi.org/10.1016/j.pnsc.2017.08.015

W. Wang, Y. Wang, J. Huang, R. Yu, J. Yang, and S. Chen, Joining of Cf/SiC Composite and Stainless Steel via Ag+Ti Filler In-Situ Alloying, J. Mater. Process. Technol., 2019, 274, p 116295. https://doi.org/10.1016/j.jmatprotec.2019.116295

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saltık, S., Esen, Z. & Dericioglu, A.F. A Comparative Study of Effects of Additive Particle Size and Content on Wetting Behavior and Brazing Performance of C/SiC Composite. J. of Materi Eng and Perform 32, 5946–5955 (2023). https://doi.org/10.1007/s11665-022-07522-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07522-9