Abstract

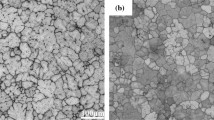

Dynamic recrystallization (DRX) plays an important role in microstructure evolution during hot deformation. In this paper, the hot deformation behavior and DRX mechanism of 7075 aluminum alloy were investigated by hot compression tests at a temperature of 250-450 °C and strain rate of 0.01-10 s−1. The experimental results show that the DRX is the main softening mechanism of the AA7075, and the relationships among temperature, strain rate and Z parameter were established. Besides that, the recrystallization fraction and grain size increase with the rising of temperature (250-450 °C) due to the accelerating of the grain boundary migration and movement. As the values of Z parameters increase, three typical softening mechanisms occur, ranging from discontinuous dynamic recrystallization (DDRX) to continuous dynamic recrystallization (CDRX). The characteristic of DDRX is mainly grain boundary (GB) bulging relying on GB migration. With regard to the situation of CDRX, the transformation of low angle grain boundary to high angle grain boundary due to the rearrangement of dislocation could be observed based on the electron backscatter diffraction analysis. The mechanism of CDRX and DDRX existed simultaneously in condition of moderate Z parameter.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

J. Hirsch, Recent Development in Aluminum for Automotive Applications, Trans. Nonferrous Met. Soc. China, 2014, 24, p 1995–2002.

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminum Alloys, Mater. Des., 2014, 56, p 862–871.

R. Kaçar and K. Güleryüz, Effect of Quenching Rate and Pre-Strain on the Strain Ageing Behaviors of 7075 Aluminum Alloys, Mater. Res., 2015, 18, p 328–333.

G. Meng, B.L. Li, H.M. Li, H. Huang, and Z.R. Nie, Hot Deformation Behavior of an Al-5.7 wt.%Mg Alloy with Erbium, Mater. Sci. Eng. A, 2009, 516, p 131–137.

L. Zhen, H.E. Hu, X.Y. Wang, B.Y. Zhang, and W.Z. Shao, Distribution Characterization of Boundary Misorientation Angle of 7050 Aluminum Alloy after High-Temperature Compression, J. Mater. Process. Technol., 2009, 209, p 754–761.

S. Gao, Z.J. Tan, L. Lan, G.X. Lu, and B. He, Experimental Investigation and Numerical Simulation of Residual Stress and Distortion of Ti6Al4V Components Manufactured Using Selective Laser Melting, J. Mater. Eng. Perform., 2022, 202, p 1–11.

T. Sakai, H. Miura, A. Goloborodko, and O. Sitdikov, Continuous Dynamic Recrystallization during the Transient Severe Deformation of Aluminum Alloy 7475, Acta Mater., 2009, 57, p 153–162.

A.M. Wusatowska-Sarnek, H. Miura, and T. Sakai, Nucleation and Microtexture Development under Dynamic Recrystallization of Copper, Mater Sci. Eng. A, 2002, 323, p 177–186.

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions, Prog. Mater. Sci., 2014, 60, p 130–207.

X.Y. Liu, Q.L. Pan, Y.B. He, W.B. Li, W.J. Liang, and Z.M. Yin, Flow Behavior and Microstructural Evolution of Al-Cu-Mg-Ag Alloy during Hot Compression Deformation, Mater. Sci. Eng. A, 2009, 500, p 150–154.

J.H. Zhao, Y.L. Deng, T. Jia, and J. Zhang, Effect of Strain Rate on the Recrystallization Mechanism during Isothermal Compression in 7050 Aluminum Alloy, Mater. Sci. Eng. A, 2018, 734, p 120–128.

H. Zhang, N.P. Jin, and J.H. Chen, Hot Deformation Behavior of Al-Zn-Mg-Cu-Zr Aluminum Alloys during Compression at Elevated Temperature, Trans. Nonferrous Met. Soc. China, 2011, 21, p 437–442.

M.A. Jabbari Taleghani, E.M. Ruiz Navas, M. Salehi, and J.M. Torralba, Hot Deformation Behavior and Flow Stress Prediction of 7075 Aluminum Alloy Powder Compacts during Compression at Elevated Temperatures, Mater. Sci. Eng. A, 2012, 534, p 624–631.

S. Wang, J.R. Luo, L.G. Hou, J.S. Zhang, and L.Z. Zhuang, Physically Based Constitutive Analysis and Microstructural Evolution of AA7050 Aluminum Alloy during Hot Compression, Mater. Des., 2016, 107, p 277–289.

M. Rajamuthamilselvan, and S. Ramanathan, Hot Deformation Behavior of 7075 Alloy, J. Alloy. Compd., 2011, 509, p 948–952.

K.P. Rao and Y.V.R.K. Prasad, High Temperature Deformation Kinetics of Al-4Mg Alloy, J. Mech. Sci. Technol., 1986, 13, p 83–95.

C.M. Sellars and W.J. Mctegart, On the Mechanism of Hot Deformation, Acta Metall., 1966, 14, p 1136–1138.

C. Zener and J.H. Hollomon, Effect of Strain Rate upon Plastic Flow of Steel, J. Appl. Phys., 1994, 15, p 22–32.

S. Gourdet and F. Montheillet, An Experimental Study of the Recrystallization Mechanism during Hot Deformation of Aluminum, Mater. Sci. Eng. A, 2000, 283(1–2), p 274–288.

Y.S. Wu, Z. Liu, X.Z. Qin, C.S. Wang, and L.Z. Zhou, Effect of Initial State on Hot Deformation and Dynamic Recrystallization of Ni-Fe Based Alloy GH984G for Steam Boiler Applications, J. Alloy. Compd., 2019, 795, p 370–384.

X.T. Zhong, L. Wang, L.K. Huang, and F. Liu, Transition of Dynamic Recrystallization Mechanism during Hot Deformation of Incoloy 028 Alloy, J. Mater. Sci. Technol., 2020, 42, p 241–253.

R. Kaibyshev, K. Shipilova, and F. Musin, Continuous Dynamic Recrystallization in an Al-Li-Mg-Sc Alloy during Equal-Channel Angular Extrusion, Mater. Sci. Eng. A, 2005, 396(1–2), p 341–351.

F. Gao, Y. Xu, and B. Song, Substructural Changes during Hot Deformation of an Fe-26Cr Ferritic Stainless Steel, Metall. Mater. Trans. A, 2000, 31, p 21–27.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Y., Ding, H. Hot Deformation Behavior of Al-Zn-Mg-Cu Alloy during Compression Tests. J. of Materi Eng and Perform 32, 4585–4596 (2023). https://doi.org/10.1007/s11665-022-07409-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07409-9