Abstract

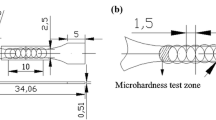

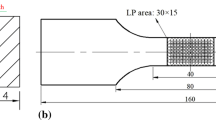

The effect of multiple laser shock peening (LSP) on the microstructure, residual stress, and mechanical strength of 2.5 Ni-Cr-Mo, low-alloy steel (EN25) is investigated. LSP treatment is carried out for laser power density (LPD) in the range of 2.8 to 4.95 GW cm−2 with different laser impacts and by maintaining an overlap of 70% and 58% along scanning direction and perpendicular directions, respectively. LSP-treated samples are characterized by residual stress, microstructural evolution, and mechanical strength. Single, double, and triple LSP treatments at 3.53 GW cm−2 enhanced compressive residual stress at the surface by ~ − 520, ~ − 640, and ~ − 680 MPa compared to the as-received sample (− 100 MPa). In addition, for double and triple LSP impacts, the compressive residual stress is found at higher depths (850 and 965 µm) than single LSP (660 µm). XRD peak broadening analysis confirmed grain refinement and micro-strain in the LSP-treated samples. Further, the dislocation density increases with the number of laser impacts. As a result of microstructural refinement and creation of high dislocation density, the hardness in triple LSP-treated samples is increased by nearly 26% as compared to the unpeened one. Twenty percent improvement in yield strength and 12.5% improvement in ultimate tensile strength are observed in triple LSP-treated samples as compared to unpeened sample.

Graphical Abstract

Similar content being viewed by others

References

Z.J. Xie, C.J. Shang, X.L. Wang, X.M. Wang, G. Han and R.D.K. Misra, Recent Progress in Third-Generation Low Alloy Steels Developed under M3 Microstructure Control, Int. J. Miner. Metall. Mater., 2020, 27(1), p 1–9.

M.A.S. Torres and H.J.C. Voorwald, An Evaluation of Shot Peening, Residual Stress and Stress Relaxation on the Fatigue Life of AISI 4340 Steel, Int. J. Fatigue, 2002, 24(8), p 877–886.

D. Závodská, M. Guagliano, O. Bokůvka and L. Trško, Fatigue Resistance of Low Alloy Steel after Shot Peening, Mater. Today Proc., 2016, 3(4), p 1220–1225.

V. Llaneza and F.J. Belzunce, Study of the Effects Produced by Shot Peening on the Surface of Quenched and Tempered Steels: Roughness, Residual Stresses and Work Hardening, Appl. Surf. Sci., 2015, 356, p 475–485. https://doi.org/10.1016/j.apsusc.2015.08.110

S.M. Hassani-Gangaraj, A. Moridi, M. Guagliano, A. Ghidini and M. Boniardi, The Effect of Nitriding, Severe Shot Peening and Their Combination on the Fatigue Behavior and Micro-Structure of a Low-Alloy Steel, Int. J. Fatigue, 2014, 62, p 67–76. https://doi.org/10.1016/j.ijfatigue.2013.04.017

H. Kovacı, I. Hacısalihoğlu, A.F. Yetim and A. Çelik, Effects of Shot Peening Pre-Treatment and Plasma Nitriding Parameters on the Structural, Mechanical and Tribological Properties of AISI 4140 Low-Alloy Steel, Surf. Coat. Technol., 2019, 358, p 256–265.

R. Karimbaev, Y.S. Pyun, E. Maleki, O. Unal and A. Amanov, An Improvement in Fatigue Behavior of AISI 4340 Steel by Shot Peening and Ultrasonic Nanocrystal Surface Modification, Mater. Sci. Eng. A, 2020, 791, p 139752. https://doi.org/10.1016/j.msea.2020.139752

J. Wu, H. Liu, P. Wei, Q. Lin and S. Zhou, Effect of Shot Peening Coverage on Residual Stress and Surface Roughness of 18CrNiMo7-6 Steel, Int. J. Mech. Sci., 2020, 183, p 105785.

P.P. Shukla, P.T. Swanson and C.J. Page, Laser Shock Peening and Mechanical Shot Peening Processes Applicable for the Surface Treatment of Technical Grade Ceramics: A Review, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2014, 228(5), p 639–652. https://doi.org/10.1177/0954405413507250

A.K. Gujba and M. Medraj, Laser Peening Process and Its Impact on Materials Properties in Comparison with Shot Peening and Ultrasonic Impact Peening, Materials (Basel), 2014, 7(12), p 7925–7974. https://doi.org/10.3390/ma7127925

A. Azhari, S. Sulaiman and A.K.P. Rao, A Review on the Application of Peening Processes for Surface Treatment, Conf. Ser. Mater. Sci. Eng., 2016, 114, p 12002. https://doi.org/10.1088/1757-899x/114/1/012002

Y. Wang, X. Pan, X. Wang, Z. Liu, S. Liu, W. Wan and P. Wang, Influence of Laser Shock Peening on Surface Integrity and Tensile Property of High Strength Low Alloy Steel, Chin. J. Aeronaut., 2020 https://doi.org/10.1016/j.cja.2020.09.004

P. Peyre, X. Scherpereel, L. Berthe, C. Carboni, R. Fabbro, G. Béranger and C. Lemaitre, Surface Modifications Induced in 316L Steel by Laser Peening and Shot-Peening. Influence on Pitting Corrosion Resistance, Mater. Sci. Eng. A, 2000, 280(2), p 294–302. https://doi.org/10.1016/S0921-5093(99)00698-X

J.Z. Lu, K. Luo, Y. Zhang, G. Sun, Y. Gu, J. Zhou, X.D. Ren, X.-C. Zhang, L.F. Zhang, K.M. Chen, C. Cui and Y. Jiang, Grain Refinement Mechanism of Multiple Laser Shock Processing Impacts on ANSI 304 Stainless Steel, Acta Mater., 2010, 58, p 5354–5362.

K.Y. Luo, J.Z. Lu, Y.K. Zhang, J.Z. Zhou, L.F. Zhang, F.Z. Dai, L. Zhang, J.W. Zhong and C.Y. Cui, Effects of Laser Shock Processing on Mechanical Properties and Micro-Structure of ANSI 304 Austenitic Stainless Steel, Mater. Sci. Eng. A, 2011, 528(13–14), p 4783–4788.

O. Takakuwa, K. Yamamiya and H. Soyama, An Indicator for the Suppression of Fatigue Crack Growth by Hybrid Peening, J. Solid Mech. Mater. Eng., 2013, 7(3), p 357–371.

J. Epp and H.-W. Zoch, Comparison of Alternative Peening Methods for the Improvement of Fatigue Properties of Case-Hardened Steel Parts, HTM J. Heat Treat. Mater., 2016, 71(3), p 109–116. https://doi.org/10.3139/105.110288

Y. Shadangi, K. Chattopadhyay, S.B. Rai and V. Singh, Effect of LASER Shock Peening on Microstructure, Mechanical Properties and Corrosion Behavior of Interstitial Free Steel, Surf. Coat. Technol., 2015, 280, p 216–224. https://doi.org/10.1016/j.surfcoat.2015.09.014

A.S. Gill, A. Telang and V.K. Vasudevan, Characteristics of Surface Layers Formed on Inconel 718 by Laser Shock Peening with and without a Protective Coating, J. Mater. Process. Technol., 2015, 225, p 463–472.

C. Correa, L. Ruiz De Lara, M. Díaz, A. Gil-Santos, J.A. Porro and J.L. Ocaña, Effect of Advancing Direction on Fatigue Life of 316L Stainless Steel Specimens Treated by Double-Sided Laser Shock Peening, Int. J. Fatigue, 2015, 79, p 1–9. https://doi.org/10.1016/j.ijfatigue.2015.04.018

L. Zhou, W. He, S. Luo, C. Long, C. Wang, X. Nie, G. He, X. Shen and Y. Li, Laser Shock Peening Induced Surface Nanocrystallization and Martensite Transformation in Austenitic Stainless Steel, J. Alloys Compd., 2016, 655, p 66–70. https://doi.org/10.1016/j.jallcom.2015.06.268

L. Petan, J.L. Ocana and J. Grum, Influence of Laser Shock Peening Pulse Density and Spot Size on the Surface Integrity of X2NiCoMo18-9-5 Maraging Steel, Surf. Coat. Technol., 2016, 307, p 262–270. https://doi.org/10.1016/j.surfcoat.2016.08.088

J.Z. Lu, B. Han, C.Y. Cui, C.J. Li and K.Y. Luo, Electrochemical and Pitting Corrosion Resistance of AISI 4145 Steel Subjected to Massive Laser Shock Peening Treatment with Different Coverage Layers, Opt. Laser Technol., 2016, 2017(88), p 250–262.

A.S. Gill, A. Telang, C. Ye, S.R. Mannava, D. Qian and V.K. Vasudevan, Localized Plastic Deformation and Hardening in Laser Shock Peened Inconel Alloy 718SPF, Mater. Charact., 2018, 142, p 15–26. https://doi.org/10.1016/j.matchar.2018.05.010

G. Xu, K.Y. Luo, F.Z. Dai and J.Z. Lu, Effects of Scanning Path and Overlapping Rate on Residual Stress of 316L Stainless Steel Blade Subjected to Massive Laser Shock Peening Treatment with Square Spots, Appl. Surf. Sci., 2019, 481(March), p 1053–1063.

S. Prabhakaran, S. Kalainathan, P. Shukla and V.K. Vasudevan, Residual Stress, Phase, Microstructure and Mechanical Property Studies of Ultrafine Bainitic Steel through Laser Shock Peening, Opt. Laser Technol., 2019, 115, p 447–458. https://doi.org/10.1016/j.optlastec.2019.02.041

S. Chupakhin, B. Klusemann, N. Huber and N. Kashaev, Application of Design of Experiments for Laser Shock Peening Process Optimization, Int. J. Adv. Manuf. Technol., 2019, 102(5–8), p 1567–1581.

P. Ganesh, A.K. Rai, P.K. Dwivedi, A. Chowdhury, R. Biswal, D.C. Nagpure, R. Sundar, R.K. Gupta, K. Ranganathan, K.S. Bindra and R. Kaul, Study on Enhancing Fatigue Life of SAE 9260 Spring Steel with Surface Defect Through Laser Shock Peening, J. Mater. Eng. Perform., 2019, 28(4), p 2029–2035. https://doi.org/10.1007/s11665-019-03990-8

A.K. Rai, R. Biswal, R.K. Gupta, S.K. Rai, R. Singh, U.K. Goutam, K. Ranganathan, P. Ganesh, R. Kaul and K.S. Bindra, Enhancement of Oxidation Resistance of Modified P91 Grade Ferritic-Martensitic Steel by Surface Modification Using Laser Shock Peening, Appl. Surf. Sci., 2019, 495, p 1436.

A.K. Rai, R. Biswal, R.K. Gupta, R. Singh, S.K. Rai, K. Ranganathan, P. Ganesh, R. Kaul and K.S. Bindra, Study on the Effect of Multiple Laser Shock Peening on Residual Stress and Microstructural Changes in Modified 9Cr-1Mo (P91) Steel, Surf. Coat. Technol., 2019, 358, p 125–135. https://doi.org/10.1016/j.surfcoat.2018.11.027

D. Liu, Y. Shi, J. Liu and L. Wen, Effect of Laser Shock Peening on Corrosion Resistance of 316L Stainless Steel Laser Welded Joint, Surf. Coat. Technol., 2019, 378(7089), p 124824. https://doi.org/10.1016/j.surfcoat.2019.07.048

P. Yella, K.V. Rajulapati, G.V.P. Reddy, R. Sandhya, P.P. Kiran, R.K. Buddu and K.B.S. Rao, Effect of Laser Shock Peening on High Cycle Fatigue Characteristics of 316LN Stainless Steel, Int. J. Press. Vessel. Pip., 2019, 176, p 103972. https://doi.org/10.1016/j.ijpvp.2019.103972

T. Bhardwaj, M. Shukla, A.K. Rai, R. Biswal, K. Ranganathan, P. Ganesh, K.S. Bindra and R. Kaul, Experimental Investigation of Multiple Laser Shock Peening on Mechanical Properties of Laser Sintering Additively Manufactured Maraging Steel, J. Mater. Eng. Perform., 2021, 30(11), p 8515–8528. https://doi.org/10.1007/s11665-021-06049-9

M. Tsuyama, Y. Kodama, Y. Miyamoto, I. Kitawaki, M. Tsukamoto and H. Nakano, Effects of Laser Peening Parameters on Plastic Deformation in Stainless Steel, J. Laser Micro Nanoeng., 2016, 11(2), p 227–231.

R. Bikdeloo, G.H. Farrahi, A. Mehmanparast and S.M. Mahdavi, Multiple Laser Shock Peening Effects on Residual Stress Distribution and Fatigue Crack Growth Behaviour of 316L Stainless Steel, Theor. Appl. Fract. Mech., 2020, 105, p 102429. https://doi.org/10.1016/j.tafmec.2019.102429

Y.X. Ye, T. Xuan, Z.C. Lian, Y.Y. Feng and X.J. Hua, Investigation of the Crater-like Microdefects Induced by Laser Shockprocessing with Aluminum Foil as Absorbent Layer, Appl. Surf. Sci., 2015, 339(1), p 75–84.

S. Bagherifard, D. Hickey, S. Fintová, F. Pastorek, I. Fernandez-Pariente, M. Bandini, T. Webster and M. Guagliano, Effects of Nanofeatures Induced by Severe Shot Peening (SSP) on Mechanical, Corrosion and Cytocompatibility Properties of Magnesium Alloy AZ31, Acta Biomater., 2017, 66, p 93–108.

R. Sundar, C. Sudha, A.K. Rai, P. Ganesh, A. Kolhatkar, S. Murugesan, V. Karthik, R. Biswal, S. Raju, K. Ranganathan, R. Kaul and K.S. Bindra, Effect of Laser Shock Peening on the Microstructure, Tensile and Heat Transport Properties of Alloy D9, Lasers Manuf. Mater. Process., 2020, 7(3), p 259–277.

L. Guan, Z.X. Ye, X.Y. Yang, J.M. Cai, Y. Li, Y. Li, Y.K. Zhang and G. Wang, Pitting Resistance of 316 Stainless Steel after Laser Shock Peening: Determinants of Microstructural and Mechanical Modifications, J. Mater. Process. Technol., 2020, 2021, p 294.

P. Taylor, G.K. Williamson and R.E. Smallman, Dislocation Densities in Some Annealed and Cold-Worked Metals from Measurements on the X-ray Debye- Scherrer, Spectrum, 2012, 2006, p 37–41.

O. Unal and R. Varol, Surface Severe Plastic Deformation of AISI 304 via Conventional Shot Peening, Severe Shot Peening and Repeening, Appl. Surf. Sci., 2015, 351, p 289–295. https://doi.org/10.1016/j.apsusc.2015.05.093

R. Sun, Z. Cao, Y. Zhang, H. Zhang, Y. Yu, Z. Che, J. Wu, S. Zou and W. Guo, Laser Shock Peening of SiCp/2009Al Composites: Microstructural Evolution, Residual Stress and Fatigue Behavior, Materials (Basel), 2021, 14(5), p 1–13.

F.M. Haggag, R.K. Nanstad, J.T. Hutton, D.L. Thomas and R.L. Swain, Use of Automated Ball Indentation Testing to Measure Flow Properties and Estimate Fracture Toughness in Metallic Materials, ASTM Spec. Tech. Publ., 1990, 1092, p 188–208.

G.X. Lu, J.D. Liu, H.C. Qiao, Y.Z. Zhou, T. Jin, X.F. Sun and Z.Q. Hu, Nonuniformity of Morphology and Mechanical Properties on the Surface of Single Crystal Superalloy Subjected to Laser Shock Peening, J. Alloys Compd., 2016, 658, p 721–725. https://doi.org/10.1016/j.jallcom.2015.10.238

M.D. Mathew, J.G. Kumar, V. Ganesan and K. Laha, Ball Indentation Studies on the Effect of Nitrogen on the Tensile Properties of 316LN SS, High Temp. Mater. Process., 2015, 34(8), p 827–832.

K. Sharma, P.K. Singh, V. Bhasin and K.K. Vaze, Automated Ball Indentation Technique for Tensile Properties Measurement of Cold Worked Stainless, Trans. SMiRT, 2011, 21, p 6–11.

Acknowledgments

The authors would like to express their gratitude to Mr. Lalit, LAML, LTD, RRCAT, for fabricating the sample holders required for laser peening EN25 samples and providing assistance throughout the laser peening experiments. The authors would like to express their appreciation to Mr. Pravin S. Hedaoo LTD, RRCAT for offering mechanical assistance for the maintenance of the laser shock peening facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Muthukumaran, G., Rai, A.K., Gautam, J. et al. A Study on Effect of Multiple Laser Shock Peening on Microstructure, Residual Stress, and Mechanical Strength of 2.5 Ni-Cr-Mo (EN25) Low-Alloy Steel. J. of Materi Eng and Perform 32, 4361–4375 (2023). https://doi.org/10.1007/s11665-022-07402-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07402-2