Abstract

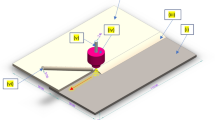

In a previous study, the tensile strength of dissimilar friction welded joints that was composed between commercially pure Al (AA1070) and low carbon steel (LCS) decreased with increasing forge pressure. This result was not applicable to the general consequence of friction welding. To prevent a decrease in the tensile strength of joints by the increase in forge pressure, the improving method of tensile strength in friction welding was investigated. Two types of AA1070 with different tensile properties due to tempering condition were used, and the weld faying part of the specimen had various overhang lengths and weld diameters. Dissimilar friction welded joints, which were composed with those AA1070 side specimens and LCS specimens, were made with various forge pressures. Then, the relationship between the tensile strength of the joints and the forge pressure was evaluated. The tensile property of AA1070 base metals with various compression stresses was also investigated, and the result was compared with the tensile strength of joints. The decrease in the tensile strength of the friction welded joints with added high forge pressure, which had an AA1070 base metal fracture, could be prevented by changing of the shape at the weld faying part of the specimen and tempering condition of the AA1070 side. However, such a joint should be made with a suitable forge pressure with the AA1070 side fracture and the same tensile strength as that of its base metal since the consideration of the decrease in the tensile strength of joints by greater forge pressure can be ignored.

Similar content being viewed by others

References

J. Kaspar, S.A. Choudry and M. Vielhaber, Concurrent Selection of Material and Joining Technology—Holistically Relevant Aspects and Its Mutual Interrelations in Lightweight Engineering, Procedia CIRP, 2018, 72, p 780–785.

D. Li and I.T. Kim, Multi-material Topology Optimization for Practical Lightweight Design, Struct. Multidiscipl. Optim., 2018, 58(3), p 1081–1094.

Technical Committee on Structural Transition Joint, Studies on the Properties of Aluminium Alloy-Steel Transition Pieces for Structural Transition Joint (STJ) of Ship Superstructure, J. Light Metar. Weld. Constr., 1978, 16(8), p 345–364. (in Japanese)

Y. Ueda and M. Niinomi, On the Alloy Layers Formed by the Reaction, J. Jpn. Inst. Light Met., 1978, 42(6), p 543–549. (in Japanese)

S. Sasabe, T. Matsumoto, T. Iwase, Y. Hattori and T. Miono, Study on the Factors in Creating the IMC Free Region-Dissimilar Metal Joining of Aluminum Alloys to Steel in MIG-Braze Welding by Using the Advanced Hot-Dip Aluminized Steel Sheet, Q. J. Jpn. Weld. Soc., 2010, 28(1), p 54–60. (in Japanese)

G.H.S.F.L. Carvalho, I. Galvão, R. Mendes, R.M. Leal and A. Loureiro, Formation of Intermetallic Structures at the Interface of Steel-to-Aluminium Explosive Welds, Mater. Charact., 2018, 2018(142), p 432–442.

Y. Gyo, T. Tsumura and K. Nakata, Dissimilar Welding of Titanium Alloys to Steels, Trans. JWRI, 2012, 41(2), p 7–12.

American Welding Society, Welding Handbook 7th Ed., Vol 4 American Welding Society, Miami, FL, 1982, p 537–538

M. Kimura, H. Ishii, M. Kusaka, K. Kaizu and A. Fuji, Joining Phenomena and Joint Strength of Friction Welded Joint Between Pure Aluminium and Low Carbon Steel, Sci. Technol. Weld. Join., 2009, 14(5), p 388–395.

H. Wang, G. Qin, P. Geng and X. Ma, Interfacial Microstructures and Mechanical Properties of Friction Welded Al/Steel Dissimilar Joints, J. Manuf. Process., 2020, 49, p 18–25.

H. Ochi, K. Ogawa, Y. Yamamoto, G. Kawai and T. Sawai, Formation of Intermetallic Compounds in Friction-Welded Joint of Aluminum Alloys to Copper and Its Influence on Joint Efficiency, Q. J. Jpn. Weld. Soc., 2003, 21(3), p 381–388. (in Japanese)

W.B. Lee and S.B. Jung, Effect of Microstructural Variation on the Cu/CK45 Carbon Steel Friction Weld Joint, Z. Metallku., 2003, 94(12), p 1300–1306.

A. Fuji, K. Ameyama, H. Kokawa, Y. Satoh and T.H. North, Properties of As welded and Heat Treated Pure Titanium-7075 Al-Zn-Mg Alloy Friction Weld Joints, Sci. Technol. Weld. Join., 2001, 6(1), p 23–30.

M. Kimura, H. Ishii, M. Kusaka, K. Kaizu and A. Fuji, Joining Phenomena and Joint Strength of Friction Welded Joint Between Aluminium-Magnesium Alloy (AA5052) and Low Carbon Steel, Sci. Technol. Weld. Join., 2009, 14(7), p 655–661.

M. Kimura, K. Suzuki, M. Kusaka and K. Kaizu, Effect of Friction Welding Condition on Joining Phenomena and Mechanical Properties of Friction Welded Joint Between 6063 Aluminium Alloy and AISI 304 Stainless Steel, J. Manuf. Process., 2017, 26, p 178–187.

M. Kimura, Y. Saitoh, M. Kusaka, K. Kaizu and A. Fuji, Effect of Friction Welding Condition and Weld Faying Surface Properties on Tensile Strength of Friction Welded Joint Between Pure Titanium and Pure Copper, J. Solid Mech. Mater. Eng., 2011, 5(12), p 849–865.

American Welding Society, Welding Handbook 8th Ed., Vol 2 American Welding Society, Miami, FL, 1991, p 739–763

M. Kimura, M. Kusaka, K. Kaizu, K. Nakata and K. Nagatsuka, Friction Welding Technique and Joint Properties of Thin-Walled Pipe Friction Welded Joint Between Type 6063 Aluminum Alloy and AISI 304 Austenitic Stainless Steel, Int. J. Adv. Manuf. Technol., 2016, 82(1), p 489–499.

J. Nakamura, M. Kimura, M. Kusaka and K. Kaizu, Joint Strength and Pipe Prerequisite Condition for Welding of Dissimilar Thin Pipe Joint Between 5052 Al Alloy and 304 Stainless Steel Fabricated by Friction Welding, Trans. Jpn. Soc. Mech. Eng., 2019, 85(880), p 19–00202. (in Japanese)

Analysis Data Sheet for A1070BD-F, no. B6110205, Washin Kogyo Co., Ltd., Osaka, 2016 (in Japanese).

Analysis Data Sheet for A1070BE-H112, no. 15104036, UACJ Extrusion Oyama Corporation, Tochigi, 2015 (in Japanese).

Analysis Data Sheet for S15CK, no. 6-04-0102, Aichi Steel Corporation, Tochigi, 2015 (in Japanese).

M. Kimura, M. Kusaka, K. Seo and A. Fuji, Relationship Between the Friction Time, Friction Torque, and Joint Properties of Friction Welding for the Low Heat Input Friction Welding Method, Q. J. Jpn. Weld. Soc., 2002, 20(4), p 559–565. (in Japanese)

T. Sawai, K. Ogawa, H. Yamaguchi, H. Ochi, Y. Yamamoto and Y. Suga, Relationship Between Diameter of Base Material and Heat Input in Friction Welding of 6061 Aluminum Alloy, J. Jpn. Inst. Light Metar., 2002, 52(2), p 7–11. (in Japanese)

M. Kimura, M. Choji, M. Kusaka, K. Seo and A. Fuji, Effect of Friction Welding Conditions on Mechanical Properties of A5052 Aluminium Alloy Friction Welded Joint, Sci. Technol. Weld. Join., 2006, 11(2), p 209–215.

Y. Kusumoto, M. Kimura, M. Kusaka and K. Kaizu, Investigation of Improving Methods for Tensile Strength of Pure Aluminium/Low Carbon Steel Friction Welded Joints with High Forge Pressure, Natl. Meet. Jpn. Weld. Soc., 2018, 103, p 94–95. (in Japanese)

Y. Kusumoto, M. Kimura, M. Kusaka and K. Kaizu, Investigation for improving joint tensile strength of A1070/S15CK friction welded joints with high forge pressure, Preprints of the National Meeting of Jpn, Weld. Soc., 2017, 101, p 300–301. (in Japanese)

M. Kimura, M. Kusaka, K. Seo and Y. Muramatsu, Properties and Improvement of Super Fine Grained Steel Friction Welded Joint, Sci. Technol. Weld. Join., 2006, 11(4), p 448–454.

Japanese Industrial Standards Committee, JIS H 0001 Aluminium, Magnesium and their Alloys—Temper Designation, JAPANESE Industrial Standards Committee, Tokyo, 1998 (in Japanese).

N. Tsuji, Y. Ito, Y. Saito and Y. Minamino, Strength and Ductility of Ultrafine Grained Aluminum and Iron Produced by ARB and Annealing, Scr. Mater., 2002, 47(12), p 893–899.

O. Noguchi, The Properties of Aluminum Sheet for Press Forming, Furukawa-Sky Rev., 2013, 9, p 3–10. (in Japanese)

A. Seeger, J. Diehi, S. Mader and H. Rebstock, Work-Hardening and Work-Softening of Facecentred Cubic Metal Crystals, Philos. Mag. J. Theor. Exp. Appl. Phys., 1957, 2, p 323–350.

G. Saada, On Hardening Due to the Recombination of Dislocations, Acta Mater., 1960, 8(12), p 841–847.

L.M. Brown, Orowan’s Explanation of the Bauschinger Effect, Scr. Mater., 1977, 11(2), p 127–131.

T. Yakou and T. Hasegawa, Present State of Research on the Bauschinger Effect, Tetsu-to-Hagane, 1984, 70(11), p 1551–1558. (in Japanese)

Acknowledgments

The authors wish to thank the staff members of the Machine and Workshop Engineering at the Graduate School of Engineering, University of Hyogo.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kimura, M., Kusumoto, Y., Kusaka, M. et al. Improving the Tensile Strength Between Pure Al and Low Carbon Steel Joint Fabricated by Friction Welding. J. of Materi Eng and Perform 32, 4655–4667 (2023). https://doi.org/10.1007/s11665-022-07396-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07396-x