Abstract

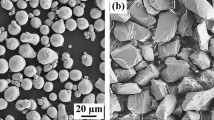

In situ synthesized Al3Ti/AlNi/AlNi3/MgNi2-reinforced composite coatings were fabricated on AZ91D magnesium alloy by laser cladding using a mixture of Al, Ti and Ni-C powders. Al layer was adopted as a middle layer for avoiding much evaporation of Mg substrate at high heat input. Phase composition, microstructures and surface properties of coatings and the substrate were studied. The interfaces between the substrate, middle layer, and cover layer presented good metallurgical bonding, and no crack was found in the interior. Tiny gray Al3Ti and large white axiolitic AlNi + Al3Ti particles were synthesized in 10 wt.% and 20 wt.% TiNiC coatings, while AlNi + Al3Ti was replaced by MgNi2 + AlNi3 + Al3Ti with polygonal and irregular shape in 30 wt.% TiNiC coating, and in this coating tinier Al3Ti tended to aggregate. Matrix phases in three coatings were α-Al + Al3Mg2 and Al12Mg17 + Al3Mg2, respectively. The formation of intermetallic compounds increased the hardness of the coating. The maximum hardness value is 368.27HV0.1 in the coating with 30 wt.% TiNiC, which was about 5.93 times that of the AZ91D substrate (62HV0.1). The friction coefficient, wear rate and wear track also showed that wear resistance of coatings was better than substrate and increased with the increase in TiNiC content. Corrosion resistance of the coatings is all improved significantly compared with the substrate.

Similar content being viewed by others

References

B.L. Mordike and T. Ebert, Magnesium: Properties-Applications-Potential, Mater. Sci. Eng. A Struct., 2001, 302, p 37–45.

V.V. Ramalingam, P. Ramasamy, M.D. Kovukkal and G. Myilsamy, Research and Development in Magnesium Alloys for Industrial and Biomedical Applications: A Review, Met. Mater. Int., 2020, 26, p 409–430.

W. Yao, W. Liang, G. Huang, B. Jiang, A. Atrens and F. Pan, Superhydrophobic Coatings for Corrosion Protection of Magnesium Alloys, J. Mater. Sci. Technol., 2020, 52, p 100–118.

J.E. Gray and B. Luan, Protective Coatings on Magnesium and its Alloys—A Critical Review, J. Alloys Compd., 2002, 336, p 88–113.

D. Seifzadeh and Z. Rajabalizadeh, Environmentally-Friendly Method for Electroless Ni–P Plating on Magnesium Alloy, Surf. Coat. Tech., 2013, 218, p 119–126.

C. Blawert, W. Dietzel, E. Ghali and G. Song, Anodizing Treatments for Magnesium Alloys and Their Effect on Corrosion Resistance in Various Environments, Adv. Eng. Mater., 2006, 8, p 511–533.

C.D. Gu, W. Yan, J.L. Zhang and J.P. Tu, Corrosion Resistance of AZ31B Magnesium Alloy with a Conversion Coating Produced from a Choline Chloride—Urea based Deep Eutectic Solvent, Corros. Sci., 2016, 106, p 108–116.

H. Hoche, J. Schmidt, S. Groß, T. Troßmann and C. Berger, PVD Coating and Substrate Pretreatment Concepts for Corrosion and Wear Protection of Magnesium Alloys, Surf. Coat. Tech., 2011, 205, p 145–150.

A. Riquelme, M.D. Escalera-Rodriguez, P. Rodrigo and J. Rams, Role of Laser Cladding Parameters in Composite Coating (Al-SiC) on Aluminum Alloy, J. Therm. Spray Techn., 2016, 25, p 1177–1191.

T. Tokunaga, M. Ohno and K. Matsuura, Coatings on Mg Alloys and their Mechanical Properties: A Review, J. Mater. Sci. Technol., 2018, 34, p 1119–1126.

M. Zhong and W. Liu, Laser Surface Cladding: The State of the Art and Challenges, Proc. Inst. Mech. Eng. C: J. Mech., 2010, 224, p 1041–1060.

E. Toyserkani, A. Khajepour and S. Corbin, Laser Cladding, CRC Press, Boca Raton, 2005.

A. Dziadoń, R. Mola and L. Błaż, The Microstructure of the Surface Layer of Magnesium Laser Alloyed with Aluminum and Silicon, Mater. Charact., 2016, 118, p 505–513.

Y. Gao, C. Wang, H. Pang, H. Liu and M. Yao, Broad-Beam Laser Cladding of Al–Cu Alloy Coating on AZ91HP Magnesium Alloy, Appl. Surf. Sci., 2007, 253, p 4917–4922.

Y. Gao, C. Wang, Q. Lin, H. Liu and M. Yao, Broad-Beam Laser Cladding of Al–Si Alloy Coating on AZ91HP Magnesium Alloy, Surf. Coat. Tech., 2006, 201, p 2701–2706.

X. Zhang, K. Zhang and J. Zou, Microstructures and Properties in Surface Layers of Mg-6Zn-1Ca Magnesium Alloy Laser-Clad with Al-Si Powders, Trans. Nonferr. Metal. Soc., 2018, 28, p 96–102.

E. Chen, K. Zhang and J. Zou, Laser Cladding of a Mg based Mg-Gd-Y-Zr Alloy with Al-Si Powders, Appl. Surf. Sci., 2016, 367, p 11–18.

Z. Zhang, K. Zhang, J. Zou and Y. Diao, Laser Cladding of a Mg-Nd-Zn-Zr Alloy with Al-Si/Al2O3 Powders, Rare Metal Mater. Eng., 2017, 46, p 2594–2600.

A. Riquelme, P. Rodrigo, M. Dolores Escalera-Rodriguez and J. Rams, Characterisation and Mechanical Properties of Al/SiC Metal Matrix Composite Coatings Formed on ZE41 Magnesium Alloys by Laser Cladding, Res. Phys., 2019, 13, p 1–11.

Y.H. Liu, Z.X. Guo, Y. Yang, H.Y. Wang, J.D. Hu and Y.X. Li, Laser (a Pulsed Nd:YAG) Cladding of AZ91D Magnesium Alloy with Al and Al2O3 Powders, Appl. Surf. Sci., 2006, 253, p 1722–1728.

B.J. Zheng, X.M. Chen and J.S. Lian, Microstructure and Wear Property of Laser Cladding Al+SiC Powders on AZ91D Magnesium Alloy, Opt. Laser Eng., 2010, 48, p 526–532.

Y. Liu, S. Gao and W. Zhao, Laser Cladding of Mg-Zn-Y-Zr Alloy using Al with Different Ratios of Micro- and Nano-SiC Powder, J Mater. Sci., 2020, 55, p 13270–13293.

H. Baker, ASM Handbook Volume 3: Alloy Phase Diagrams, 10th ed. ASM International, Materials Park, 1992.

T.M. Yue and T. Li, Laser Cladding of Ni/Cu/Al Functionally Graded Coating on Magnesium Substrate, Surf. Coat. Tech., 2008, 202, p 3043–3049.

T.M. Yue, A.H. Wang and H.C. Man, Corrosion Resistance Enhancement of Magnesium ZK60/SiC Composite by Nd:YAG Laser Cladding, Scr. Mater., 1999, 40, p 303–311.

Y. Guo, Y. Zhang, Z. Li, S. Wei, T. Zhang and L. Yang, Microstructure and Properties of In-Situ Synthesized ZrC-Al3Zr Reinforced Composite Coating on AZ91D Magnesium Alloy by Laser Cladding, Surf. Coat. Tech., 2018, 334, p 471–478.

Y.H. Zhou, Z.H. Zhang, Y.P. Wang, G. Liu, S.Y. Zhou, Y.L. Li, J. Shen and M. Yan, Selective Laser Melting of Typical Metallic Materials: An Effective Process Prediction Model Developed by Energy Absorption and Consumption Analysis, Addit. Manuf., 2019, 25, p 204–217.

L. Yang, Z. Li, Y. Zhang, S. Wei and F. Liu, Al-TiC In Situ Composite Coating Fabricated by Low Power Pulsed Laser Cladding on AZ91D Magnesium Alloy, Appl. Surf. Sci., 2018, 435, p 1187–1198.

Y.H. Lv, J. Li, Y.F. Tao and L.F. Hu, High-Temperature Wear and Oxidation Behaviors of TiNi/Ti2Ni Matrix Composite Coatings with TaC Addition Prepared on Ti6Al4V by Laser Cladding, Appl. Surf. Sci., 2017, 402, p 478–494.

H. Okamoto, Al-Mg (Aluminum-Magnesium), J. Phase Equilib., 1998, 19, p 598–598.

I. Barin. Thermochemical Data of Pure Substances, Third edition, VCH, (2008)

M. Zhang, Y. Liu, X. Yang, J. An, K. Luo, Effect of Graphite Particle Size on Wear Property of Graphite and Al2O3 Reinforced AZ91D-0.8%Ce Composites, Trans. Nonferr. Metal Soc. 18, 273–277 (2008)

A. Baradeswaran and A.E. Perumal, Study on Mechanical and Wear Properties of Al 7075/Al2O3/Graphite Hybrid Composites, Compos. Part. B: Eng., 2014, 56, p 464–471.

I. Aatthisugan, A.R. Rose and D.S. Jebadurai, Mechanical and Wear Behaviour of AZ91D Magnesium Matrix Hybrid Composite Reinforced with Boron Carbide and Graphite, J. Magnes. Alloy., 2017, 5, p 20–25.

H. Chen and A.T. Alpas, Sliding Wear Map for the Magnesium Alloy Mg-9Al-0.9 Zn (AZ91), Wear, 2000, 246(1–2), p 106–116.

Acknowledgments

This work was financially supported by the Natural Science Foundation of Shanxi Province of China (201901D111174).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Jin, K., Li, Z. et al. Microstructures, Wear and Corrosion Behaviors of Laser Cladding In Situ Synthetic Al3Ti/AlNi/AlNi3/MgNi2 Composite Coatings on Magnesium Alloy using Al as Middle Layer. J. of Materi Eng and Perform 32, 4216–4228 (2023). https://doi.org/10.1007/s11665-022-07370-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07370-7