Abstract

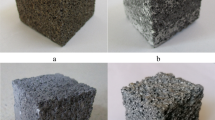

The present paper investigates the stabilization of Mg-3Ca alloy and Mg-3Ca/SiC/5p composite foams with and without the addition of 0.12 wt.% beryllium. In Mg-3Ca alloy foam, Be addition has shown a significant improvement in the expansion and pore structure. Whereas, in case of Mg-3Ca/SiC/5p composite foams, the SiC particles stabilized the foam effectively, while Be addition does not show any distinguishable improvement in the foam structure. The formation of BeO and the dense coverage of SiC particles in the gas–solid interface of Mg-3Ca and Mg-3Ca/SiC/5p composite foams, respectively, are the reasons for the foam stabilization. Mg-3Ca/SiC/5p composite foam exhibited lowest foam density of 0.10 g/cm3. The quasi-static compression test shows that Mg-3Ca-0.12Be/SiC/5p composite foam containing Be exhibited lower foam density and higher normalized compressive strength. The energy absorption capacity per unit foam density in Be containing foams was also higher.

Similar content being viewed by others

References

D.H. Yang, C. Seo and B.Y. Hur, Mg Alloy Foam Fabrication Via Melt Foaming Method, J. Mater. Sci. Technol., 2008, 24, p 302.

D.H. Yang, B.Y. Hur and S.R. Yang, Study on Fabrication and Foaming Mechanism of Mg Foam Using CaCO3 as Blowing Agent, J. Alloys Compd., 2008, 46, p 221.

X. Xia, J. Feng, J. Ding, K. Song, X. Chen, W. Zhao and B.Y. Hur, Fabrication and Characterization of Closed-Cell Magnesium-Based Composite Foams, Mater. Des., 2015, 74, p 36.

X.C. Xia, X.W. Chen, Z. Zhang, X. Chen, W.M. Zhao, B. Liao and B.Y. Hur, Effects of Porosity and Pore Size on the Compressive Properties of Closed-Cell Mg Alloy Foam, J. Magnes. Alloy., 2013, 1, p 330.

M. Sakamoto, S. Akiyama and K. Ogi, Suppression of Ignition and Burning of Molten Mg Alloys by Ca Bearing Stable Oxide Film, J. Mater. Sci. Lett., 1997, 16, p 1048.

X.Q. Zeng, Q.D. Wang, Y.Z. Lu, W.J. Ding, C. Lu, Y.P. Zhu, C.Q. Zhai and X.P. Xu, Kinetic Study on the Surface Oxidation of the Molten Mg-9Al-0.5Zn-0.3Be Alloy, J. Mater. Sci., 2001, 36, p 2499.

T.R. Neu, M. Mukherjee, F. Garcia-Moreno and J. Banhart, International conference on porous metal and metallic foams. B.Y. Hur, B.K. Kim, S.E. Kim, S.K. Hyun Ed., GS Intervision, Seoul, 2012, p 139

T.S. Shih, J.H. Wang and K.Z. Chong, Combustion of Magnesium Alloys in Air, Mater. Chem. Phys., 2004, 85, p 302.

Y.B. Huang, I.S. Chung, B.S. You, W.W. Park and B.H. Choi, Effect of Be Addition on the Oxidation Behavior of Mg-Ca Alloys At Elevated Temperature, Met. Mater. Int., 2004, 10, p 7.

S.H. Ha, J.K. Lee and S.K. Kim, Effect of CaO on Oxidation Resistance and Microstructure of Pure Mg, Mater. Trans., 2008, 49, p 1081.

S. Akiyama, Flame-resistant magnesium alloys by calcium, J. Jpn. Foundry Eng. Soc., 1994, 66, p 38.

T.S. Shih, J.B. Liu and P.S. Wei, Oxide Films on Magnesium and Magnesium Alloys, Mater. Chem. Phys., 2007, 104, p 497.

Q. Tan, N. Mo, B. Jiang, F. Pan, A. Atrens and M.X. Zhang, Oxidation Resistance of Mg-9Al-1Zn Alloys Micro-Alloyed with Be, Scr. Mater., 2016, 115, p 28.

D.H. Yang, Y. Shang-Run, W. Hui, M. Ai-Bin, J. Jing-Hua, C. Jian-Qing and W. Ding-Lie, Compressive Properties of Cellular Mg Foams Fabricated by Melt-Foaming Method, Mater. Sci. Eng. A, 2010, 525, p 5405.

S.H. Park, K.H. Song, Y.S. Um and B.Y. Hur, Rheological Characteristics of Mg-Al Alloys with Ceramic Particles for Metal Foam, Mater. Sci. Forum, 2006, 510, p 742.

D. Bhosale, A. Devikar, S. Sasikumar and G.S. Vinod Kumar, Foaming Mg Alloy and Composite Using MgCO3 blowing agent, Metall. Mater. Trans. B, 2021, 52, p 931.

T. Miyoshi, M. Itoh, S. Akiyama and A. Kitahara, ALPORAS Aluminum Foam: Production Process, Properties and Applications, Adv. Eng. Mater., 2000, 2, p 179.

V. Gergely, D.C. Curran and T.W. Clyne, The FOAMCARP Process: Foaming of Aluminium MMCs by the Chalk-Aluminium Reaction in Precursors, Compos. Sci. Technol., 2003, 63, p 2301.

J.D. Bryant, M. Crowley, W. Wang, D. Wilhelmy and J. Kallivayalil, International conference on porous metals and metallic foams. L.P. Lefebvre, J. Banhart, D. Dunand Ed., DEStech Publication, Pennsylvania, 2008, p 19

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson and H.N.G. Wadley, Metal foams: a design guide, Butterworth-Heinemann, Burlington, 2000, p 40

M. Mukherjee, F. Garcia-Moreno and J. Banhart, Collapse of Aluminum Foam in Two Different Atmospheres, Metall. Mater. Trans. B, 2010, 41, p 500.

K. Heim, G.S. Vinod-Kumar, F. García-Moreno, A. Rack and J. Banhart, Stabilisation of Aluminium Foams and Films by the Joint Sction of Dispersed Particles and Oxide Films, Acta Mater., 2015, 99, p 313.

M. Mukherjee, U. Ramamurty, F. Garcia-Moreno and J. Banhart, The Effect of Cooling Rate on the Structure and Properties of Closed-Cell Aluminium Foams, Acta Mater., 2010, 58, p 5031.

I.J.T. Jensen, A. Thogersen, O.M. Lovvik, H. Schreuders, B. Dam and S. Diplas, X-ray Photoelectron Spectroscopy Investigation of Magnetron Sputtered Mg-Ti-H thin films, Int. J. Hydrogen Energy, 2013, 38, p 10704.

A. Marin, C.P. Lungu and C. Porosnicu, Influence of Gaseous Environments on Beryllium–Tungsten and Tungsten Surfaces Investigated by XPS, J. Vac. Sci. Technol., 2017, 35, e021403.

B. Luo, J. Zhang, Y. He, L. Chen, J. Luo, K. Li and W. Wu, An Investigation Progress Toward Be-Based Ablator Materials for the Inertial Confinement Fusion, High Power Laser Sci. Eng., 2017, 5, p 1.

Z.G. Xu, J.W. Fu, T.J. Luo and Y.S. Yang, Effects of Cell Size on Quasi-Static Compressive Properties of Mg Alloy Foams, Mater. Des., 2012, 34, p 40.

E.Y. Shafirovich and U.I. Goldshleger, Combustion of Magnesium Particles in CO2/CO mixtures, Combust Sci Technol, 1992, 84, p 33–43.

S. Wang, Y. Wang, Q. Ramasse and Z. Fan, The Nature of Native MgO in Mg and its Alloys, Metall. Mater. Trans. A, 2020, 51, p 2957.

R.D. Heidenbreich, Electron Reflections in MgO Crystals with the Electron Microscope, Phys. Rev., 1942, 62, p 291.

G.S. Vinod Kumar, F. García-Moreno, J. Banhart and A. Kennedy, The Stabilising Effect of Oxides in Foamed Aluminium Alloy Scrap, Int. J. Mater. Res., 2005, 106(9), p 978.

J. Campbell, Castings, Butterworth-Heinemann, Oxford, 2003, p 17

K.B. Wikle, Improving aluminum castings with beryllium, AFS Trans., 1978, 78, p 513.

X. Zeng, Q. Wang, Y. Lü, W. Ding, Y. Zhu, C. Zhai, C. Lu and X. Xu, Behavior of Surface Oxidation on Molten Mg-9Al-0.5Zn-0.3Be Alloy, Mater. Sci. Eng. A, 2001, 301, p 154.

A. Haibel, A. Rack and J. Banhart, Why are metal foams stable?, Appl. Phys. Lett., 2006, 89, p 2004.

G.S. Vinod Kumar, B.S. Murty and M. Chakraborty, Settling Behaviour of TiAl3, TiB2, TiC and AlB2 Particles in Liquid Al During Grain Refinement, Int. J. Cast Met. Res., 2010, 23(4), p 193.

N. Babcsan, G.S. Vinod Kumar, B.S. Murty and J. Banhart, Grain Refiners as Liquid Metal Foam Stabilisers, Trans. Indian Inst. Met., 2007, 60(2–3), p 127.

C. Koerner, Integral foam molding of metals. In: Integral foam molding of light metals, (Springer, Berlin, Heidelberg 2008) p. 27.

K. Stobener, J. Baumeister and G. Rausch, New Concept for Series Manufacturing: Aluminium Foam in Industrial Production, ATZ Worldw., 2005, 107, p 2.

D. Yang, Z. Hu, W. Chen, J. Lua, J. Chen, H. Wang, L. Wang, J. Jiang and A. Ma, Fabrication of Mg-Al Alloy Foam with Close-Cell Structure by Powder Metallurgy Approach and its Mechanical Properties, J. Manuf. Process., 2016, 22, p 290.

X. Lu, Z. Zhang, H. Du, H. Luo, Y. Mu and J. Xu, Compressive Behavior of Mg Alloy Foams at Elevated Temperature, J. Alloys Compd., 2019, 797, p 727.

X. Xia, W. Zhao, Z. Wei and Z. Wang, Effects of Specimen Aspect Ratio on the Compressive Properties of Mg Alloy Foam, Mater. Des., 2012, 42, p 32.

G. Lu, H. Hao, F. Wang and X. Zhang, Preparation of Closed-Cell Mg Foams Using SiO2-Coated CaCO3 as Blowing Agent in Atmosphere, Trans. Nonferrous Met. Soc. China, 2013, 23, p 1832.

L. Lefebvre and E. Baril, Effect of Oxygen Concentration and Distribution on the Compression Properties on Titanium Foams, Adv. Eng. Mater., 2008, 10(9), p 868.

S. Yu, Y. Luo and J. Liu, Effects of Strain Rate and SiC Particle on the Compressive Property of SiCp/AlSi9Mg Composite Foams, Mater. Sci. Eng. A, 2008, 487, p 394.

Acknowledgment

The authors thank DST-SERB, Government of India, for funding of the work under EMR grant no. EMR/2016/006207. The first author also thanks Mr. D. Bhosale, Mr. S. Sasikumar, and Dr. K. Georgy for their support in experimental work and characterization. The third author acknowledges the funding received from the Ministry of Human Resource and Development for the Centre of Excellence (CoE) in Applied Magnesium Research (A Vertical of Centre for Materials and Manufacturing for Futuristic Mobility), IIT Madras (grant number SB20210992MEMHRD008517).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Magnesium. The issue was organized by Prof. C. (Ravi) Ravindran, Dr. Raja Roy, Mr. Payam Emadi, and Mr. Bernoulli Andilab, Ryerson University.

Rights and permissions

About this article

Cite this article

Devikar, A., Muduli, B., Mukherjee, M. et al. Stabilization and Mechanical Properties of Mg-3Ca and Mg-3Ca/SiC/5p Foams Alloyed with Beryllium. J. of Materi Eng and Perform 32, 2700–2709 (2023). https://doi.org/10.1007/s11665-022-07369-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07369-0