Abstract

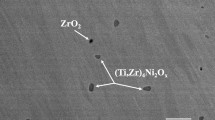

The present work explores the phase transition characteristics of a shape memory alloy (SMA), Ni50.7Ti49.3 (at.%), studied under three different types of partial thermal cycling, namely M⇌M + A (Type I), A ⇌ A + M (Type II) and M + A ⇌ M + A (Type III), based on the temperature range and the phases involved during the phase transformation. The partial thermal cycling tests were conducted using a differential scanning calorimeter (DSC) by varying the maximum and minimum temperatures of a cycle, while the presence of phases at different temperatures was confirmed by XRD analysis. It is observed that Type I partial cycling suppresses the appearance of the intermediate R phase during thermal cycling. Also, during Type II and Type III partial cycling, the phase changes take place in two steps, i.e., R phase to B2 (first stage) and B19’ to B2 (second stage). The area under the transformation curve corresponding to the first stage enlarges with increasing cycles, while that corresponding to the second stage decreases with them. All this is because of the change in the volume fraction of the alloy taking part during the phase changes and the generation of dislocation during thermal cycling. Partial cycling results in a higher stability of phase transition temperatures as compared to that for full cycling.

Similar content being viewed by others

Data availability

The raw data that support the findings of this study are available in one of the author's research gate profiles (controlled access repository). https://www.researchgate.net/publication/359392939_Raw_data_for_Partial_Cycling_of_NiTi_SMA.

References

K. Otsuka and X. Ren, Physical Metallurgy of Ti-Ni-Based Shape Memory Alloys, Prog. Mater. Sci., 2005, 50(5), p 511–678. https://doi.org/10.1016/j.pmatsci.2004.10.001

D.E. Hodgson, W.H. Ming and R.J. Biermann, Shape Memory Alloys, ASM Int. Met. Handb. Tenth Ed., 1990, 2, p 897–902.

B. Li, L. Wang, B. Wang, D. Li, J.P. Oliveira, R. Cui, J. Yu, L. Luo, R. Chen, Y. Su, J. Guo and H. Fu, Tuning the Microstructure, Martensitic Transformation and Superelastic Properties of EBF3-Fabricated NiTi Shape Memory Alloy Using Interlayer Remelting, Mater. Des., 2022, 220, p 110886. https://doi.org/10.1016/j.matdes.2022.110886

B. Li, L. Wang, B. Wang, D. Li, J.P. Oliveira, R. Cui, J. Yu, L. Luo, R. Chen, Y. Su, J. Guo and H. Fu, Electron Beam Freeform Fabrication of NiTi Shape Memory Alloys: Crystallography, Martensitic Transformation, and Functional Response, Mater. Sci. Eng. A, 2022, 843, p 143135. https://doi.org/10.1016/j.msea.2022.143135

K. Otsuka, A. Saxena, J. Deng and X. Ren, Mechanism of the Shape Memory Effect in Martensitic Alloys: An Assessment, Philos. Mag., 2011, 91(36), p 4514–4535.

Z.K. Lu and G.J. Weng, Martensitic Transformation and Stress-Strain Relations of Shape-Memory Alloys, J. Mech. Phys. Solid, 1997, 45(11–12), p 1905–1921.

J. Mohd-Jani, M. Leary, A. Subic and M.A. Gibson, A Review of Shape Memory Alloy Research, Applications and Opportunities, Mater. Des., 2014, 56, p 1078–1113. https://doi.org/10.1016/j.matdes.2013.11.084

L. Petrini and F. Migliavacca, Biomedical Applications of Shape Memory Alloys, J. Metall., 2011, 2011, p 1–15.

C. Menna, F. Auricchio, and D. Asprone Applications of Shape Memory Alloys in Structural Engineering. In: Shape Memory Alloy Engineering: For Aerospace, Structural and Biomedical Applications. Elsevier, (2015). https://doi.org/10.1016/B978-0-08-099920-3.00013-9.

A.R. Pelton, V. Schroeder, M.R. Mitchell, X.Y. Gong, M. Barney and S.W. Robertson, Fatigue and Durability of Nitinol Stents, J. Mech. Behav. Biomed. Mater., 2008, 1(2), p 153–164.

D.C. Lagoudas, D.A. Miller, L. Rong and P.K. Kumar, Thermomechanical Fatigue of Shape Memory Alloys, Smart Mater. Struct., 2009, 18(8), p 1–12.

G. Eggeler, E. Hornbogen, A. Yawny, A. Heckmann and M. Wagner, Structural and Functional Fatigue of NiTi Shape Memory Alloys, Mater. Sci. Eng. A, 2004, 378(1–2), p 24–33.

S.K. Bhaumik, C.N. Saikrishna, K.V. Ramaiah and M.A. Venkataswamy, Understanding the Fatigue Behaviour of NiTiCu Shape Memory Alloy Wire Thermal Actuators, Key Eng. Mater., 2008, 378, p 301–316.

J.P. Oliveira, R.M. Miranda, N. Schell and F.M.B. Fernandes, High Strain and Long Duration Cycling Behavior of Laser Welded NiTi Sheets, Int. J. Fatigue, 2016, 83, p 195–200. https://doi.org/10.1016/j.ijfatigue.2015.10.013

S. Miyazaki, Y. Igo and K. Otsuka, Effect of Thermal Cycling on the Transformation Temperatures of TiNi Alloys, Acta Metall., 1986, 34(10), p 2045–2051.

S. Yang, T. Omori, C. Wang, Y. Liu, M. Nagasako, J. Ruan, R. Kainuma, K. Ishida and X. Liu, A Jumping Shape Memory Alloy under Heat, Sci. Rep., 2015, 2016(6), p 2–7. https://doi.org/10.1038/srep21754

M. Prasher, D. Sen, R. Tewari and M. Krishnan, Tuning the Thermal Cyclic Stability of Martensitic Transformation in Ni50.3Ti29.7Hf20 High Temperature Shape Memory Alloy, Mater. Res. Bull., 2021, 133, p 111056.

J. Perkins and P. Bobowiec, Microstructural Effects of Martensitic Transformation Cycling of a Cu-Zn-Al Alloy: Vestigial Structures in the Parent Phase, Metall. Trans. A Phys. Metall. Mater. Sci., 1986, 17(2), p 195–203.

J. Zhang, C. Somsen, T. Simon, X. Ding, S. Hou, S. Ren, X. Ren, G. Eggeler, K. Otsuka and J. Sun, Leaf-like Dislocation Substructures and the Decrease of Martensitic Start Temperatures: A New Explanation for Functional Fatigue during Thermally Induced Martensitic Transformations in Coarse-Grained Ni-Rich Ti-Ni Shape Memory Alloys, Acta Mater., 2012, 60(5), p 1999–2006. https://doi.org/10.1016/j.actamat.2011.12.014

R.F. Hamilton, H. Sehitoglu, Y. Chumlyakov and H.J. Maier, Stress Dependence of the Hysteresis in Single Crystal NiTi Alloys, Acta Mater., 2004, 52(11), p 3383–3402.

C. Urbina, S. De la Flor and F. Ferrando, Effect of Thermal Cycling on the Thermomechanical Behaviour of NiTi Shape Memory Alloys, Mater. Sci. Eng. A, 2009, 501(1–2), p 197–206.

T. Liu, Y. Zheng and L. Cui, Influence of Partial Cycling on the Transformation Mass of NiTi Alloys, Mater. Lett., 2013, 112, p 121–123. https://doi.org/10.1016/j.matlet.2013.09.012

J. Rodriguez-Aseguinolaza, I. Ruiz-Larrea, M.L. No, A. Lopez-Echarri and J. San-Juan, The Influence of Partial Cycling on the Martensitic Transformation Kinetics in Shape Memory Alloys, Intermetallics, 2009, 17(9), p 749–752.

W. Tang and R. Sandström, Analysis of the Influence of Cycling on TiNi Shape Memory Alloy Properties, Mater. Des., 1993, 14(2), p 103–113.

G. Airoldi, A. Corsi and G. Riva, The Hysteresis Cycle Modification in Thermoelastic Martensitic Transformation of Shape Memory Alloys, Scr. Mater., 1997, 36(11), p 1273–1278.

G. Airoldi, S. Besseghini and G. Riva, Electric Transport Properties Modified by Incomplete Cycling on Heating (ICH) in TiNi Based Alloys, J. Phys., 1995, 5(2), p C2-483-C2-488.

Z. Wang, X. Zu and Y. Fu, Review on the Temperature Memory Effect in Shape Memory Alloys, Int. J. Smart Nano Mater., 2011, 2(3), p 101–119.

A.A. Karakalas, T.T. Machairas, and D.A. Saravanos, Exploration of the Partial Transformation Behaviour of Shape Memory Alloys and Its Effect on Actuation Performance. In: Behavior and Mechanics of Multifunctional Materials XIII, (2019), p. 109680D.

J.K. Strelec, D.C. Lagoudas, M.A. Khan and J. Yen, Design and Implementation of a Shape Memory Alloy Actuated Reconfigurable Airfoil, J. Intell. Mater. Syst. Struct., 2003, 14(4–5), p 257–273.

H.M. Paranjape, M.L. Bowers, M.J. Mills and P.M. Anderson, Mechanisms for Phase Transformation Induced Slip in Shape Memory Alloy Micro-Crystals, Acta Mater., 2017, 132, p 444–454. https://doi.org/10.1016/j.actamat.2017.04.066

T. Simon, A. Kröger, C. Somsen, A. Dlouhy and G. Eggeler, On the Multiplication of Dislocations during Martensitic Transformations in NiTi Shape Memory Alloys, Acta Mater., 2010, 58(5), p 1850–1860.

A.R. Pelton, G.H. Huang, P. Moine and R. Sinclair, Effects of Thermal Cycling on Microstructure and Properties in Nitinol, Mater. Sci. Eng. A, 2012, 532, p 130–138. https://doi.org/10.1016/j.msea.2011.10.073

G.B. Stachowiak and P.G. McCormick, Shape Memory Behaviour Associated with the R and Martensitic Transformations in a NiTi Alloy, Acta Metall., 1988, 36(2), p 291–297.

Y. Zheng, F. Jiang, L. Li, H. Yang and Y. Liu, Effect of Ageing Treatment on the Transformation Behaviour of Ti-50.9 at.% Ni Alloy, Acta Mater., 2008, 56(4), p 736–745.

J. Uchil, K.G. Kumara and K.K. Mahesh, Effect of Thermal Cycling on R-Phase Stability in a NiTi Shape Memory Alloy, Mater. Sci. Eng. A, 2002, 332(1–2), p 25–28.

Y. Liu, J. Laeng, T.V. Chin and T.H. Nam, Partial Thermal Cycling of NiTi, J. Alloys Compd., 2008, 449(1–2), p 144–147.

M. Krishnan, New Observations on the Thermal Arrest Memory Effect in Ni-Ti Alloys, Scr. Mater., 2005, 53(7), p 875–879.

Z.G. Wang, X.T. Zu, Y.Q. Fu and L.M. Wang, Temperature Memory Effect in TiNi-Based Shape Memory Alloys, Thermochim. Acta, 2005, 428(1–2), p 199–205.

L.D.A. Santos, P.D. Resende, M.G.D.A. Bahia and V.T.L. Buono, Effects of R-Phase on Mechanical Responses of a Nickel-Titanium Endodontic Instrument: Structural Characterization and Finite Element Analysis, Sci. World J., 2016, 2016, p 1–11.

X. Wang, J. Van Humbeeck, B. Verlinden and S. Kustov, Thermal Cycling Induced Room Temperature Aging Effect in Ni-Rich NiTi Shape Memory Alloy, Scr. Mater., 2016, 113, p 206–208. https://doi.org/10.1016/j.scriptamat.2015.11.007

Z. Zhang, R.D. James and S. Müller, Energy Barriers and Hysteresis in Martensitic Phase Transformations, Acta Mater., 2009, 57(15), p 4332–4352.

J. Khalil-Allafi, A. Dlouhy and G. Eggeler, Ni4Ti3-Precipitation during Aging of NiTi Shape Memory Alloys and Its Influence on Martensitic Phase Transformations, Acta Mater., 2002, 50(17), p 4255–4274.

Acknowledgments

The authors gratefully acknowledge the financial support from the Science and Engineering Research Board, Department of Science and Technology, India, under grant number CRG/2019/002267. The authors would also like to acknowledge the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI—Hyderabad) for allowing us to conduct the high-temperature XRD tests.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ganesan, S., Vedamanickam, S. Transformation Behavior of a Shape Memory Ni50.7Ti49.3 (at.%) Alloy during Partial Thermal Cycling. J. of Materi Eng and Perform 32, 2501–2508 (2023). https://doi.org/10.1007/s11665-022-07284-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07284-4