Abstract

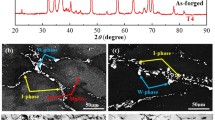

The corrosion resistance of mechanically clinched interstitial free (IF) steel–Mg joints was investigated by potentiodynamic and immersion corrosion tests in 3.5% NaCl solution at 25 C. The initial microstructure influenced the corrosion performance of studied joints due to the formation of secondary phases and their volume fraction changed the galvanic corrosion response of Mg materials. Nd-La addition enhanced the corrosion resistance of IF-Mg joints, where two times higher corrosion resistance was obtained by IF-AZ31B-0.5Nd-0.1La (1110 mils/year (mpy)) joint than IF-AZ31B (3670 mpy). The cross section locations had different secondary phase (SP) volume fraction, SP-distribution and grain orientations which altered the corrosion behavior of joined materials. After the clinching process, the deformed section of IF-AZ31B-0.5Nd-0.1La and IF-AZ31B showed lower corrosion rate than undeformed sections 1040 and 1110 mpy and 2820 and 3670 mpy, respectively.

Similar content being viewed by others

References

M.M. Eshtayeh, M. Hrairi and A.K.M. Mohiuddin, Clinching Process for Joining Dissimilar Materials: State of the Art, The International Journal of Advanced Manufacturing Technology 2015 82:1, Springer, 2015, 82(1), p 179–195. https://doi.org/10.1007/S00170-015-7363-0

S. Han, Y. Wu, Y. Gao, Q.Z.-2nd I.C. on, and undefined 2012, Study on Clinching of Magnesium Alloy Sheets with Different Lower Die Parameters Based on DEFORM 2D, atlantis-press.com, n.d., https://www.atlantis-press.com/proceedings/emeit-12/3492. Accessed 14 July 2022.

R. Neugebauer, S. Dietrich and C. Kraus, Dieless Clinching and Dieless Rivet-Clinching of Magnesium, Key. Eng. Mater. Trans Tech Pub. Ltd, 2007, 344, p 693–698. https://doi.org/10.4028/www.scıentıfıc.net/kem.344.693

K. Hono, C.L. Mendis, T.T. Sasaki and K. Oh-Ishi, Towards the Development of Heat-Treatable High-Strength Wrought Mg Alloys, Scripta. Mater. Pergam, 2010, 63(7), p 710–715.

F. Guo, D. Zhang, X. Yang, L. Jiang, S. Chai and F. Pan, Effect of Rolling Speed on Microstructure and Mechanical Properties of AZ31 Mg Alloys Rolled with a Wide Thickness Reduction Range, Mater. Sci. Eng. A, Elsevier Ltd, 2014, 619, p 66–72.

S.M. Ashrafizadeh, R. Mahmudi and A.R. Geranmayeh, A Comparative Study on the Effects of Gd, Y and La Rare-Earth Elements on the Microstructure and Creep Behavior of AZ81 Mg Alloy, Mater. Sci. Eng.: A, Elsevier, 2020, 790, 139712.

A. Prasad, J. Jain and N.N. Gosvami, Effect of Minor La Addition on Wear Behaviour of Mg-10Dy Alloy, Wear, Elsevier, 2021, 486–487, 204121.

K.I. Mori, N. Bay, L. Fratini, F. Micari and A.E. Tekkaya, Joining by Plastic Deformation, CIRP Ann. Manuf. Technol., 2013, 62(2), p 673–694.

R.N. Ae, R. Mauermann, A.E. Stephan, D. Ae and C. Kraus, A New Technology for the Joining by Forming of Magnesium Alloys, Production Engineering 2007 1:1, Springer, 2007, 1(1), p 65–70. https://doi.org/10.1007/S11740-007-0045-5

M.S. Gogheri, M. Kasiri-Asgarani, H.R. Bakhsheshi-Rad, H. Ghayour and M. Rafiei, In Vitro Corrosion Behavior and Cytotoxicity of Polycaprolactone – Akermanite-Coated Friction-Welded Commercially Pure Ti/AZ31 for Orthopedic Applications, J. Mater. Eng. Perform. Springer, 2020, 29(9), p 6053–6065.

H.R. Bakhsheshi-Rad, E. Hamzah, S. Farahany and Mark P. Staiger, The Mechanical Properties and Corrosion Behavior of Quaternary Mg-6Zn-0.8Mn-XCa Alloys, J. Mater. Eng. Perform, 2015, 24(2), p 598–608. https://doi.org/10.1007/s11665-014-1271-6

H.R. Bakhsheshi-Rad, E. Hamzah, H.Y. Tok, M. Kasiri-Asgarani, S. Jabbarzare and M. Medraj, Microstructure in Vitro Corrosion Behavior and Cytotoxicity of Biodegradable Mg-Ca-Zn and Mg-Ca-Zn-Bi Alloys, J. Mater. Eng. Perfor. Springer, 2017, 26(2), p 653–666.

M.S. Gogherı, M. Kasırı-Asgaranı, H.R. Bakhsheshı-Rad, H. Ghayour and M. Rafıeı, Mechanical Properties, Corrosion Behavior and Biocompatibility of Orthopedic Pure Titanium−Magnesium Alloy Screw Prepared by Friction Welding, Transact. Nonferr. Metal. Soc. China, 2020, 30(11), p 2952–2966.

S. Demirdal and F. Aydın, The Influence of Low-Cost Eggshell on the Wear and Electrochemical Corrosion Behaviour of Novel Pure mg Matrix Composites, Mater. Chem. Phys. Elsevier, 2022, 277, 125520.

Z. Yu, M. Hu, A. Tang, M. Wu, J. He, Z. Gao, F. Wang, C. Li, B. Chen and J. Liu, Effect of Aluminium on the Microstructure and Mechanical Properties of as-Cast Magnesium-Manganese Alloys, Taylor and Francis, 2017, 33(17), p 2086–2096. https://doi.org/10.1080/02670836.2017.1345824

B. Liu, Z. Wu, Y. Zhang and S. Zhang, Simultaneously Enhanced the Strength and Ductility in Mg17Al12 Intermetallic Compound with ce Addition, Mater. Lett. North-Holland., 2022, 320, 132324.

R. Manaila, D. Macovei, R. Popescu, A. Devenyi, A. Jianu, E. Vasile, P.B. Barna and J.L. Lábár, Nano-Icosahedral Al–Mn–Ce Phases: Structure and Local Configurations, Mater. Sci. Eng.: A, Elsevier, 2000, 294–296, p 82–85.

Z. T. M. Mhawesh, Corrosıon Resıstance of Mechanıcally Clınched IF Steel and Mg-3.0 Al-1.0 Zn-0.3 Mn-0.5 Nd-Xla (X= 0.1, 0.2 And 0.5) Alloy, 2021, http://acikerisim.karabuk.edu.tr:8080/xmlui/handle/123456789/1613. Accessed 15 July 2022.

M.K.S. Atia and M.K. Jain, A Novel Approach to Hot Die-Less Clinching Process for High Strength AA7075-T6 Sheets, Proc. Inst. Mech. Eng. Part C: J. Mech.l Eng. Sci. SAGE Publ. Ltd, 2020, 234(19), p 3809–3825.

H. Feng, S. Liu, Y. Du, T. Lei, R. Zeng and T. Yuan, Effect of the Second Phases on Corrosion Behavior of the Mg-Al-Zn Alloys, J. Alloys. Compound. Elsevier, 2017, 695, p 2330–2338.

M. Lotfpour, M. Emamy and C. Dehghanian, Influence of Cu Addition on the Microstructure, Mechanical, and Corrosion Properties of Extruded Mg-2%Zn Alloy, J. Mater. Eng Perform., Springer, 2020, 29(5), p 2991–3003. https://doi.org/10.1007/S11665-020-04856-0/FIGURES/16

S.H. Wu, P. Zhang, D. Shao, P.M. Cheng, J. Kuang, K. Wu, J.Y. Zhang, G. Liu and J. Sun, Grain Size-Dependent Sc Microalloying Effect on the Yield Strength-Pitting Corrosion Correlation in Al-Cu Alloys, Mater. Sci. Eng.: A, Elsevier, 2018, 721, p 200–214.

C. Yan, Y. Xin, X.B. Chen, D. Xu, P.K. Chu, C. Liu, B. Guan, X. Huang and Q. Liu, Evading Strength-Corrosion Tradeoff in Mg Alloys Via Dense Ultrafine Twins, Nature Communications 2021 12:1, Nat. Publ. Group, 2021, 12(1), p 1–9. https://doi.org/10.1038/s41467-021-24939-3

X. Di, C. Xu, J. Wu, Y. Dong and Q. Shi, Competitive Effect of Grain Size and Second Phase on Corrosion Behavior of Biodegradable Mg-3Zn-1Mn-XSr Alloys, J. Mater. Eng. Perfor. Springer, 2022, 31(4), p 3136–3150.

M. Lotfpour, M. Emamy and C. Dehghanian, Influence of cu Addition on the Microstructure, Mechanical, and Corrosion Properties of Extruded Mg-2%Zn Alloy, J. Mater. Eng. Perform. Springer, 2020, 29(5), p 2991–3003.

L. Hong, R. Wang and X. Zhang, The Role of Nd in Corrosion Properties of Mg-12Gd-2Zn-0.4Zr Alloys, J. Mater. Eng. Perform., 2021, 30(8), p 6000–6008. https://doi.org/10.1007/s11665-021-05782-5

J. Chen, G. Chen, H. Yan, B. Su, X. Gong and B. Zhou, Correlation Between Microstructure and Corrosion Resistance of Magnesium Alloys Prepared by High Strain Rate Rolling, J. Mater. Eng. Perform. Springer, 2017, 26(10), p 4748–4759.

F. Zheng, H. Chen, Y. Zhang, W. Wang and H. Nie,Microstructure Evolution and Corrosion Resistance of AZ31 Magnesium Alloy Tube by Stagger Spinning, Int. J. Minerals, Metallurgy. Mater. Univ. Sci. Technol. Beijing, 2022, 29(7), p 1361–1372.

C. Wang, L. Zeng, W. Ding and T. Liang, Effects of Minor RE (Y, La) on Microstructure and Corrosion Behavior of TX31 Alloys, J. Mater. Res. Technol. Elsevier BV, 2021, 14, p 69–80.

Acknowledgments

This work was financially supported by the Scientific Research Projects Coordination Unit of Karabük University, Project Number: FYL-2020-2254.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Magnesium. The issue was organized by Prof. C. (Ravi) Ravindran, Dr. Raja Roy, Mr. Payam Emadi, and Mr. Bernoulli Andilab, Ryerson University.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mhawesh, Z.T., Kara, İ.H. & Zeyvelı, M. Corrosion Resistance of Interstitial Free Steel and Mg Alloys Sheets Joined by Mechanical Clinching. J. of Materi Eng and Perform 32, 2793–2800 (2023). https://doi.org/10.1007/s11665-022-07221-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07221-5