Abstract

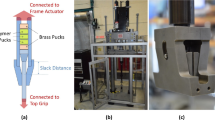

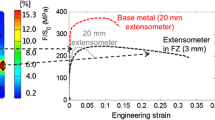

In this effort, variation of mechanical properties with the geometry of Al6061 specimens was studied, while the grain size was unchanged. Young's modulus, yield strength, ultimate tensile strength, and fracture strain of dog–bone specimens with cross sections varying from 0.4 mm × 0.4 mm to 12.7 mm × 7 mm were measured from uniaxial tension tests. Four sets of specimens were used, corresponding to varying: cross-sectional area; thickness; aspect ratio; and gauge length. Digital image correlation of natural speckles on the small specimens was used to measure full-field strains, in order to avoid the effect of additional devices or paint on the measured mechanical properties. Changes in microstructures were observed through metallography. A decrease in Young’s modulus, yield strength, ultimate tensile strength, and fracture strain was observed when the cross-sectional area, thickness, and aspect ratio were reduced while the opposite trend was seen in the reduction of the gauge length.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Code Availability

Not Applicable.

References

R.Z. Valiev, VYu. Gertsman, and O.A. Kaibyshev, The Role of Non-Equilibrium Grain Boundary Structure in Strain Induced Grain Boundary Migration (Recrystallization after small strain), Scr. Metall., 1983, 17, p 853–856. https://doi.org/10.1016/0036-9748(83)90248-X

H. Mizubayashi, Y. Yoshihara, and S. Okuda, The Elasticity Measurements of Aluminiumnm-Films, Physica Status Solidi (a), 1992, 129, p 475–481. https://doi.org/10.1002/pssa.2211290217

ASTM B577, Standard Test Methods for Tension Testing Wrought and Cast Aluminum and Magnesium-Alloy Products.

P.S. Ghangrekar, R. Banjare, C.R. Balkrishna, and H. Murthy, Tensile Testing of Al6061-T6 Microspecimens with Ultrafine-Grained Structure Derived from Machining-Based SPD Process, J. Mater. Res., 2014, 29(11), p 1278–1287. https://doi.org/10.1557/jmr.2014.115

A.V. Sergueeva, J. Zhou, B.E. Meacham, and D.J. Branagan, Gage Length and Sample Size Effect on Measured Properties During Tensile Testing, Mater. Sci. Eng. A, 2009, 526, p 79–83. https://doi.org/10.1016/j.msea.2009.07.046

W.J. Yuan, Z.L. Zhang, Y.J. Su, L.J. Qiaoa, and W.Y. Chu, Influence of Specimen Thickness with Rectangular Cross-section On the Tensile Properties of Structural Steels, Mater. Sci. Eng. A, 2012, 532, p 601–605. https://doi.org/10.1016/j.msea.2011.11.021

G. Simons, C. Weippert, and J. D., Villain J., Size effects in Tensile Testing of Thin Cold Rolled and Annealed Cu Foils, Mater. Sci. Eng. A, 2006, 416, p 290–299. https://doi.org/10.1016/j.msea.2005.10.060

C.H. Suh, Y.C. Jung, and S.K. Young, Effects of Thickness and Surface Roughness on Mechanical Properties of Aluminum Sheets, J. Mech. Sci. Technol., 2010, 24(10), p 2091–2098. https://doi.org/10.1007/s12206-010-0707-7

S. Venkatachalam, R. Banjare, H. Murthy, and B.C. Rao, Mechanical Testing of Micro-specimens of Al6061-T6 Using DIC for Strain Measurement, Exp. Tech., 2019, 43, p 125–135. https://doi.org/10.1007/s40799-018-0254-1

Z. Dong, Z. Xiaoyu, S. Wenhua, Z. Hao, L. Hongshuai, and L. Jun, Study of Size Effect on Microstructure and Mechanical Properties of AlSi10Mg Samples Made by Selective Laser Melting, Materials, 2018, 11, p 2463. https://doi.org/10.3390/ma11122463

M. Xu, Z. Xu, Z. Zhang, H. Lei, Y. Bai, and D. Fang, Mechanical properties and energy absorption capability of AuxHex structure under in-plane compression: Theoretical and experimental studies, Int. J. Mech. Sci., 2019, 159, p 43–57. https://doi.org/10.1016/j.ijmecsci.2019.05.044

X. Chen, Y. Li, X. Han, and J. Zhang, Size Effect Studies on Tensile Tests for Hot Stamping Steel, J. Mater. Eng. Perform., 2018, 27, p 640–647. https://doi.org/10.1007/s11665-018-3135-y

Y. Chen, O. Kraft, and M. Walter, Size effects in thin coarse-grained gold microwires under tensile and torsional loading, Acta Mater., 2015, 87, p 78–85. https://doi.org/10.1016/j.actamat.2014.12.034

W. Weibull, A Statistical Distribution Function of Wide Applicability, J. Appl. Mech., 1951, 18, p 290–293.

J.J. Ortega, G. Ruiz, E. Poveda, D.C. González, M. Tarifa, X.X. Zhang, R.C. Yu, M.Á. Vicente, Á. de la Rosa, and L. Garijo, Size Effect on the Compressive Fatigue of Fibre-Reinforced Concrete, Constr. Build. Mater., 2022, 322, p 126238. https://doi.org/10.1016/j.conbuildmat.2021.126238

Z.P. BazÏant, Size Effect, Int. J. Solids Struct., 2000, 37, p 69–80. https://doi.org/10.1016/S0020-7683(99)00077-3

M.I. Idiart, V.S. Deshpande, N.A. Fleck, and J.R. Willis, Size Effects in the Bending of Thin Foils, Int. J. Eng. Sci., 2009, 47(11–12), p 1251–1264. https://doi.org/10.1016/j.ijengsci.2009.06.002

T. Hoshide and H. Sugiyama, Numerical Analysis of Sample-Size Effect on Strength of Alumina, J. Mater. Eng. Perform., 2013, 22, p 1–8. https://doi.org/10.1007/s11665-012-0214-3

B. Ehrler, X.D. Hou, T.T.K.M. ZhuP’ng, C.J. Walker, A.J. Bushby, and D.J. Dunstan, Grain Size and Sample Size Interact to Determine Strength in a Soft Metal, Philos. Mag., 2008, 88(25), p 3043–3050. https://doi.org/10.1080/14786430802392548

D.S. Balint, V.S. Deshpande, A. Needleman, and E. Van der Giessen, Discrete Dislocation Plasticity Analysis of the Grain Size Dependence of the Flow Strength of Polycrystals, Int. J. Plast., 2008, 24, p 2149–2172. https://doi.org/10.1016/j.ijplas.2007.08.005

J.H. Choi, H. Kim, J.Y. Kim, K.H. Lim, B.C. Lee, and G.D. Sim, Micro-Cantilever Bending Tests for Understanding Size Effect in Gradient Elasticity, Mater. Des., 2022, 214, p 110398. https://doi.org/10.1016/j.matdes.2022.110398

O. Altun, O. Sahin, and A. Toprak, Effects of Impact and Attrition Mechanisms on Size Distribution and Liberation Characteristics of the Components, Adv. Powder Technol., 2021, 32(10), p 3550–3563. https://doi.org/10.1016/j.apt.2021.08.010

H. Yang, G. Xiaogang, H. Wang, Q. Jia, M. Yunlong, H. Lei, and H. Chen, Low-Velocity Impact Performance of Composite-Aluminum Tubes Prepared by Mesoscopic Hybridization, Compos. Struct., 2021, 274, p 114348. https://doi.org/10.1016/j.compstruct.2021.114348

P. Valat-Villain, J. Durinck, and P.O. Renault, Grain Size Dependence of Elastic Moduli in Nanocrystalline Tungsten, J. Nanomater., 2017 https://doi.org/10.1155/2017/3620910

V. Krstic, U. Erb, and G. Palumbo, Effect of Porosity on Young’s Modulus of Nanocrystalline Materials, Scripta Mater., 1993, 29(11), p 1501–1504. https://doi.org/10.1016/0956-716X(93)90344-R

P.G. Sanders, J.A. Eastman, and J.R. Weertman, Elastic and Tensile Behavior of Nanocrystalline Copper and Palladium, Acta mater., 1997, 45(10), p 4019–4025. https://doi.org/10.1016/S1359-6454(97)00092-X

G.E. Fougere, L. Riester, M. Ferber, J.R. Weertman, and R.W. Siegel, Young’s Modulus of Nanocrystalline Fe Measured by Nanoindentation, Mater. Sci. Eng. A, 1995, 204, p 1–6. https://doi.org/10.1016/0921-5093(95)09927-1

T.D. Shen, C.C. Koch, T.Y. Tsui, and G.M. Pharr, On the Elastic Moduli of Nanocrystalline Fe, Cu, Ni, and Cu-Ni Alloys Prepared by Mechanical Milling/Alloying, J. Mater. Res., 1995, 10, p 2892–2896. https://doi.org/10.1557/JMR.1995.2892

H.F. Akbary, M.J. Santofimia, and J. Sietsma, Elastic Strain Measurement of Miniature Tensile Specimens, J. Exp. Mech., 2014, 54, p 165–173. https://doi.org/10.1007/s11340-013-9785-7

A. Vinogradov, D. Orlov, A. Danyuk, and Y. Estrin, Effect of Grain Size on the Mechanisms of Plastic Deformation in Wrought Mg-Zn-Zr Alloy Revealed by Acoustic Emission Measurements, Acta Mater., 2013, 61, p 2044–2056. https://doi.org/10.1016/j.actamat.2012.12.024

Y.H. Zhao, Y.Z. Guo, Q. Wei, T.D. Topping, A.M. Dangelewicz, Y.T. Zhu, T.G. Langdon, and E.J. Lavernia, Influence of Specimen Dimensions and Strain Measurement Methods on Tensile Stress-Strain cuRves, Mater. Sci. Eng. A, 2009, 525, p 68–77. https://doi.org/10.1016/j.msea.2009.06.031

Y. Kohno, A. Kohyama, L.H. Margaret, H. Takanori, and F.A.G. YutaiKatoh, Specimen Size Effects on the Tensile Properties of JPCA and JFMS, J. Nuclear Mater., 2000, 283–287, p 1014–1017. https://doi.org/10.1016/S0022-3115(00)00245-2

L.V. Raulea, A.M. Goijaerts, L.E. Govaert, and F.P.T. Baaijens, Size Effect in the Processing of Thin Metal Sheets, J. Mater. Process. Technol., 2001, 115, p 44–48. https://doi.org/10.1016/S0924-0136(01)00770-1

W.L. Chan and M.W. Fu, Experimental and Simulation Based Study on Micro-Scaled Sheet Metal Deformation Behavior in Microembossing Process, Mater. Sci. Eng. A, 2012, 556, p 60–67. https://doi.org/10.1016/j.msea.2012.06.058

L. Zhang, W. Zhang, W. Chen, J. Duan, W. Wang, and E. Wang, The Effect of Grain Size on the Strain Hardening Behavior for Extruded ZK61 Magnesium Alloy, J. Mater. Eng. Perform., 2017, 26, p 6013–6021. https://doi.org/10.1007/s11665-017-3023-x

R.K. Mahidhara, Effect of Grain Size on the Superplastic Behavior of a 7475 Aluminum Alloy, J. Mater. Eng. Perform., 1995, 4, p 674–678.

Y.C. Huang, S.Y. Chang, and C.H. Chang, Effect of Residual Stress on Mechanical Properties and Interface adhesion Strength of SiN thin Films, Thin Solid Films, 2009, 517, p 4857–4861. https://doi.org/10.1016/j.tsf.2009.03.043

L. Zhu, B. Xu, H. Wang, and C. Wang, On the Evaluation of Residual Stress and Mechanical Properties of FeCrBSi Coatings by Nanoindentation, Mater. Sci. Eng. A, 2012, 536, p 98–102. https://doi.org/10.1016/j.msea.2011.12.078

J.F. Nye, Physical Properties of Crystals: Their Representation by Tensors and Matrices, Oxford University Press, England, 1985.

Z.J. Li, G. Winther, and N. Hansen, Anisotropy of Plastic Deformation in Rolled Aluminum, Mater. Sci. Eng. A, 2004, 387–389, p 199–202. https://doi.org/10.1016/j.msea.2004.03.090

S. Suwas and R.K. Ray, Crystallographic Texture of Materials, Springer, Heidelberg, 2014.

A. Molotnikov, R. Lapovok, C.H.J. Davies, W. Caoa, and Y. Estrin, Size Effect on The Tensile Strength of Fine-Grained Copper, Scripta Mater., 2008, 59, p 1182–1185. https://doi.org/10.1016/j.scriptamat.2008.08.004

S. Nohut, Influence of Sample Size on Strength Distribution of Advanced Ceramics, Ceram. Int., 2014, 40, p 4285–4295. https://doi.org/10.1016/j.ceramint.2013.08.093

T.A. Parthasarathy, S.I. Rao, D.M. Dimiduk, M.D. Uchic, and D.R. Trinkle, Contribution to Size Effect of Yield Strength from the Stochastics of Dislocation Source Lengths in Finite Samples, Scripta Mater., 2007, 56, p 313–316. https://doi.org/10.1016/j.scriptamat.2006.09.016

Funding

No funds, grants, or other support were received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mishra, V.D., Venkatachalam, S., Rao, B.C. et al. Size Effect Stemming from Specimen Geometry on Mechanical Properties of an Aluminum Alloy. J. of Materi Eng and Perform 32, 562–576 (2023). https://doi.org/10.1007/s11665-022-07142-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07142-3