Abstract

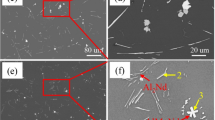

The main purpose of this research was to determine the electrochemical behavior of the anodized AZ31 magnesium alloy with different current densities immersed under watered cementice paste. These results obtained by Tafel polarization curves and electrochemical impedance spectroscopy indicated a decrease of approximately 90% in the corrosion rate for the anodized AZ31 magnesium alloy with 25 mA/cm2 when compared to a non-anodized AZ31 magnesium alloy, evidencing the protection generated by the anodization process. In addition, by means of surface SEM and SEM of the cross section, it was possible to determine the growth of the anodized layer and the morphological changes caused by the electrochemical reaction on the surface of the anodized magnesium. These results obtained in this study concluded that the anodized AZ31 magnesium alloy anodized with a current density of 25 mA/cm2 presents a set of optimum properties to be implemented in highly corrosive industry process.

Similar content being viewed by others

References

S.-K. Lee, M.-J. Jeon, S.-S. Cha and C.-G. Park, Mechanical and Permeability Characteristics of Latex-Modified Fiber-Reinforced Roller-Compacted Rapid-Hardening-Cement Concrete for Pavement Repair, Appl. Sci., 2017, 7, p 694. https://doi.org/10.3390/app7070694

H. Li, H. Xiao and J. Ou, A study on Mechanical and Pressure-Sensitive Properties of Cement Mortar with Nanophase Materials, Cem. Concr. Res., 2004, 34, p 435–438. https://doi.org/10.1016/j.cemconres.2003.08.025

J.-W. Han, J.-H. Jeon and C.-G. Park, Mechanical and Permeability Characteristics of Latex-Modified Pre-Packed Pavement Repair Concrete as a Function of the Rapid-Set Binder Content, Materials (Basel)., 2015, 8, p 6728–6737. https://doi.org/10.3390/ma8105339

O. Pospíchal, B. Kucharczyková, P. Misák and T. Vymazal, Freeze-Thaw Resistance of Concrete with Porous Aggregate, Procedia Eng., 2010, 2, p 521–529. https://doi.org/10.1016/j.proeng.2010.03.056

S.A. Walling and J.L. Provis, Magnesia-Based Cements: A Journey of 150 Years, and Cements for the Future?, Chem. Rev., 2016, 116, p 4170–4204. https://doi.org/10.1021/acs.chemrev.5b00463

J.-K. Jang, H.-G. Kim, J.-H. Kim and J.-S. Ryou, The Evaluation of Damage Effects on MgO Added Concrete with Slag Cement Exposed to Calcium Chloride Deicing Salt, Materials (Basel)., 2018, 11, p 793. https://doi.org/10.3390/ma11050793

X. Shi, M. Akin, T. Pan, L. Fay, Y. Liu and Z. Yang, Deicer Impacts on Pavement Materials: Introduction and Recent Developments, Open Civ. Eng. J., 2009, 3, p 16–27. https://doi.org/10.2174/1874149500903010016

S. Zhao, H. Zhou, T. Zhou, Z. Zhang, P. Lin and L. Ren, The Oxidation Resistance and Ignition Temperature of AZ31 Magnesium Alloy with Additions of La2O3 and La, Corros. Sci., 2013, 67, p 75–81. https://doi.org/10.1016/j.corsci.2012.10.007

A. Basheer Ahmed, Anodizing of Magnesium Alloy AZ31 by Alkaline Solution, Diyala J. Eng. Sci., 2015 https://doi.org/10.24237/djes.2015.08108

L. Girón, W. Aperador, L. Tirado, F. Franco and J.C. Caicedo, Electrochemical Performance Estimation of Anodized AZ31B Magnesium Alloy as Function of Change in the Current Density, J. Mater. Eng. Perform., 2017, 26, p 3710–3718. https://doi.org/10.1007/s11665-017-2808-2

I.B. Singh, M. Singh and S. Das, A Comparative Corrosion Behavior of Mg, AZ31 and AZ91 Alloys in 3.5% NaCl Solution, J. Magn. Alloy., 2015, 3, p 142–148. https://doi.org/10.1016/j.jma.2015.02.004

A. Srinivasan, K.S. Shin and N. Rajendran, Dynamic Electrochemical Impedance Spectroscopy (DEIS) Studies of AZ31 Magnesium Alloy in Simulated Body Fluid Solution, RSC Adv., 2014, 4, p 27791–27795. https://doi.org/10.1039/C4RA02432J

Z.L. Wang, Y.H. Yan, T. Wan and H. Yang, Poly(L-Lactic acid)/Hydroxyapatite/Collagen Composite Coatings on AZ31 Magnesium Alloy for Biomedical Application, Proc. Inst. Mech. Eng. Part H J Eng. Med., 2013, 227, p 1094–1103. https://doi.org/10.1177/0954411913493845

N. Zidane, Evaluation of the Corrosion of AZ31 Magnesium Alloy Used as Sacrificial Anode for Cathodic Protection of Hot-Water Tank Storage Containing Chloride, Int. J. Electrochem. Sci., 2018, 13, p 29–44. https://doi.org/10.20964/2018.01.36

Y. Cheng, T. Qin, H. Wang and Z. Zhang, Comparison of Corrosion Behaviors of AZ31, AZ91, AM60 and ZK60 Magnesium Alloys, Trans. Nonferrous Met. Soc. China., 2009, 19, p 517–524. https://doi.org/10.1016/S1003-6326(08)60305-2

C.H. Ortiz, J.C. Caicedo and W. Aperador, Corrosion Properties of Heterostructured [8YSZ/Al2O3]N Coatings as a Function of the Bilayer Number, J. Mater. Eng. Perform., 2021 https://doi.org/10.1007/s11665-021-06300-3

C.H. Ortiz, H.D. Colorado, W. Aperador and A. Jurado, Influence of the Number of Bilayers on the Mechanical and Tribological Properties in [TiN/TiCrN]n Multilayer Coatings Deposited by Magnetron Sputtering, Tribol. Ind., 2019, 41, p 330–343. https://doi.org/10.24874/ti.2019.41.03.03

S.A. Salman, R. Mori, R. Ichino and M. Okido, Effect of Anodizing Potential on the Surface Morphology and Corrosion Property of AZ31 Magnesium Alloy, Mater. Trans., 2010, 51, p 1109–1113. https://doi.org/10.2320/matertrans.M2009380

F.A. Bonilla, A. Berkani, Y. Liu, P. Skeldon, G.E. Thompson, H. Habazaki, K. Shimizu, C. John and K. Stevens, Formation of Anodic Films on Magnesium Alloys in an Alkaline Phosphate Electrolyte, J. Electrochem. Soc., 2002, 149, p B4. https://doi.org/10.1149/1.1424896

A. Pawlak, M. Rosienkiewicz and E. Chlebus, Design of Experiments Approach in AZ31 Powder Selective Laser Melting Process Optimization, Arch. Civ. Mech. Eng., 2017, 17, p 9–18. https://doi.org/10.1016/j.acme.2016.07.007

Acknowledgments

This research was supported by the Tribology, Polymers, Powder Metallurgy and Solid Waste Transformation (TPMR) research group of the Universidad del Valle; And the “Universidad Militar Nueva Granda” through the INV_ING 3123 project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ortiz, C.H., Aperador, W. & Caicedo, J.C. Electrochemical Study of Anodized AZ31 Magnesium Alloy (Mg/MgO) Immersed under Watered Cementice Paste. J. of Materi Eng and Perform 31, 8896–8905 (2022). https://doi.org/10.1007/s11665-022-06931-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06931-0