Abstract

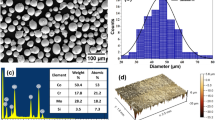

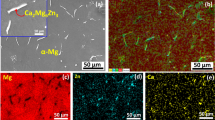

In this work, composite clads (NiCrSiB/WC/Ag/hBN and NiCrSiB/WC/MoS2/hBN) have been successfully developed using microwave cladding technique on titanium 31 substrate. The clads were characterized by field emission scanning electron microscope (FESEM), electron backscatter diffraction (EBSD), x-Ray diffraction (XRD) analysis. The developed clads were free from porosity, defects, and other thermal distortion effects. Furthermore, due to the uniform distribution of hard phases, clads achieved uniform hardness across the clad depth. The convective currents of the molten pool improved metallurgical bonding with the substrate. Because of the volumetric heating, the deviation of microhardness values in the clad was found to be low. The tribological properties of the clads were tested against an Al2O3 counterbody using a pin on disc tribometer. The results showed that incorporating solid lubricants (Ag/hBN and MoS2/hBN) into the nickel-based alloy significantly improved tribological properties. The wear rate and coefficient of friction decreased as the temperature increased from 200 to 600 °C. It was demonstrated that anti-wear and lubricating capability of both clad could be improved at elevated temperatures by doping Ag, MoS2, and hBN solid lubricants.

Similar content being viewed by others

References

Y.H. Lv, J. Li, Y.F. Tao, and L.F. Hu, High-Temperature Wear and Oxidation Behaviors of TiNi/Ti 2 Ni Matrix Composite Coatings with TaC Addition Prepared on Ti6Al4V by Laser Cladding, Appl. Surf. Sci., 2017, 402, p 478–494.

S. Zafar, and A.K. Sharma, Dry Sliding Wear Performance of Nanostructured Wc–12co Deposited Through Microwave Cladding, Tribol. Int, 2015, 91, p 14–22.

S. Zafar, and A.K. Sharma, Materials Characterization Development and Characterisations of WC–12Co Microwave Clad, Mater. Charact., 2014, 96, p 241–248.

C.D. Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, and B.H. Channabasappa, Development and Sliding Wear Behavior of Co-Mo-Cr-Si Cladding Through Microwave Heating, Silicon, Silicon, 2019.

D. Gupta, and A.K. Sharma, Development and Microstructural Characterization of Microwave Cladding on Austenitic Stainless Steel, Surface Coat. Technol., 2011, 205(21–22), p 5147–5155.

M. Minhaj, and S. Zafar, Influence of B4C Content on Flexural Performance of Ni+ B4C Microwave Composite Clads, J. Mater. Eng. Perform., 2021, 30(1), p 165–176.

M. Gupta, and W.L.E. Wong, Enhancing Overall Mechanical Performance of Metallic Materials Using Two-Directional Microwave Assisted Rapid Sintering, Scr. Mater., 2005, 52(6), p 479–483.

A. Mondal, A. Upadhyaya, and D. Agrawal, Microwave Sintering of W-18Cu and W-7Ni-3Cu Alloys, J. Microw. Power Electromagn. Energy, 2009, 43(1), p 43111–43116.

P. Chhillar, D. Agrawal, and J.H. Adair, Sintering of Molybdenum Metal Powder Using Microwave Energy, Powder Metall., 2008, 51(2), p 182–187.

K. Saitou, Microwave Sintering of Iron, Cobalt, Nickel, Copper and Stainless Steel Powders, Scr. Mater., 2006, 54(5), p 875–879.

S.S. Panda, V. Singh, A. Upadhyaya, and D. Agrawal, Sintering Response of Austenitic (316L) and Ferritic (434L) Stainless Steel Consolidated in Conventional and Microwave Furnaces, Scr. Mater., 2006, 54(12), p 2179–2183.

H. Berns, Comparison of Wear Resistant MMC and White Cast Iron, Wear, 2003, 254(1–2), p 47–54.

T.E. Abioye, P.K. Farayibi, D.G. McCartney, and A.T. Clare, Effect of Carbide Dissolution on the Corrosion Performance of Tungsten Carbide Reinforced Inconel 625 Wire Laser Coating, J. Mater. Process Technol., 2016, 231, p 89–99.

M. Afzal, M. Ajmal, A. Nusair Khan, A. Hussain, and R. Akhter, Surface Modification of Air Plasma Spraying WC-12%Co Cermet Coating by Laser Melting Technique, Opt. Laser Technol., 2014, 56, p 202–206.

X. Shi, S. Song, W. Zhai, M. Wang, Z. Xu, J. Yao, A. Qamar ud Din, and Q. Zhang, Tribological Behavior of Ni3Al Matrix Self-Lubricating Composites Containing WS2, Ag and HBN Tested from Room Temperature to 800°C,, Mater.Des, 2014, 55, p 75–84.

C.H. Ding, P.L. Li, G. Ran, and J.N. Zhou, PM304 Coating on a Ni-Based Superalloy Rod for High Temperature Lubrication, Ceram. Int., 2008, 34(2), p 279–284.

H. Torres, B. Podgornik, M. Jovičević-Klug, and M. Rodríguez Ripoll, Compatibility of Graphite, HBN and Graphene with Self-Lubricating Coatings and Tool Steel for High Temperature Aluminium Forming, Wear, 2021, 2022, p 490–491.

H. Torres, M.R. Ripoll, and B. Prakash, Self-Lubricating Laser Claddings for Friction Control during Press Hardening of Al-Si-Coated Boron Steel, J. Mater. Process. Technol., 2019, 269, p 79–90.

H. Torres, M. Rodríguez Ripoll, and B. Prakash, Tribological Behaviour of Self-Lubricating Materials at High Temperatures, Int. Mater. Rev., 2018, 63(5), p 309–340.

R. Tyagi, D. Xiong, and J. Li, Effect of Load and Sliding Speed on Friction and Wear Behavior of Silver/h-BN Containing Ni-Base P/M Composites, Wear, 2011, 270(7–8), p 423–430.

S.M. Aouadi, Y. Paudel, B. Luster, S. Stadler, P. Kohli, C. Muratore, C. Hager, and A.A. Voevodin, Adaptive Mo 2N/MoS 2/Ag Tribological Nanocomposite Coatings for Aerospace Applications, Tribol. Lett., 2008, 29(2), p 95–103.

W. Gulbiński, and T. Suszko, Thin Films of Mo2N/Ag Nanocomposite-the Structure, Mechanical and Tribological Properties, Surf. Coat Technol., 2006, 201(3–4), p 1469–1476.

S. Zhu, J. Cheng, Z. Qiao, and J. Yang, High Temperature Solid-Lubricating Materials: A Review, Tribol. Inter., 2019, 133, p 206–223.

A.M. Hebbale, and M.S. Srinath, Microstructural Studies of Cobalt Based Microwave Clad Developed on Martensitic Stainless Steel (AISI-420), Trans. Indian Inst. Met., 2018, 71(3), p 737–743.

J.F. Flores, A. Neville, N. Kapur, and A. Gnanavelu, An Experimental Study of the Erosion-Corrosion Behavior of Plasma Transferred Arc MMCs, Wear, 2009, 267(1–4), p 213–222.

T. Liyanage, G. Fisher, and A.P. Gerlich, Microstructures and Abrasive wear Berformance of PTAW Deposited Ni–WC Overlays Using Different Ni-alloy Chemistries, Wear, 2012, 274, p 345–354.

J. Li, D. Xiong, H. Wu, J. Dai, and T. Cui, Tribological Properties of Molybdenized Silver-Containing Nickel Base Alloy at Elevated Temperatures, Tribol. Int., 2009, 42(11–12), p 1722–1729.

J.S. Xu, X.C. Zhang, F.Z. Xuan, Z.D. Wang, and S.T. Tu, Microstructure and Sliding Wear Resistance of Laser Cladded WC/Ni Composite Coatings with Different Contents of WC Particle, J. Mater. Eng. Perform., 2012, 21(9), p 1904–1911.

C. Guo, J. Zhou, J. Chen, J. Zhao, Y. Yu, and H. Zhou, High Temperature Wear Resistance of Laser Cladding NiCrBSi and NiCrBSi/WC-Ni Composite Coatings, Wear, 2011, 270(7–8), p 492–498.

M. Ulutan, K. Kiliçay, O.N. Çelik, and Ü. Er, Microstructure and Wear Behaviour of Plasma Transferred Arc (PTA)-Deposited FeCrC Composite Coatings on AISI 5115 Steel, J. Mater. Process. Technol., 2016, 236, p 26–34.

G. Tosun, Ni–WC Coating on AISI 1010 Steel Using TIG: Microstructure and Microhardness, Arab. J. Sci. Eng., 2012, 39(3), p 2097–2106.

O.N. Çelik, Microstructure and Wear Properties of WC Particle Reinforced Composite Coating on Ti6Al4V Alloy Produced by the Plasma Transferred Arc Method, Appl. Surf. Sci., 2013, 274, p 334–340.

X. Luo, J. Li, and G.J. Li, Effect of NiCrBSi Content on Microstructural Evolution, Cracking Susceptibility and Wear Behaviors of Laser Cladding WC/Ni-NiCrBSi Composite Coatings, J. Alloys Compd., 2015, 626, p 102–111.

M. Surender, B. Basu, and R. Balasubramaniam, Wear Characterization of Electrodeposited Ni-WC Composite Coatings, Tribol. Int., 2004, 37(9), p 743–749.

R. Tyagi, D.S. Xiong, J.L. Li, and J. Dai, High-Temperature Friction and Wear of Ag/h-BN-Containing Ni-Based Composites against Steel, Tribol. Lett., 2010, 40(1), p 181–186.

J.J. Hu, C. Muratore, and A.A. Voevodin, Silver Diffusion and High-Temperature Lubrication Mechanisms of YSZ-Ag-Mo Based Nanocomposite Coatings, Compos. Sci. Technol., 2007, 67(3–4), p 336–347.

J.L. Li, D.S. Xiong, and M.F. Huo, Friction and Wear Properties of Ni-Cr-W-Al-Ti-MoS2 at Elevated Temperatures and Self-Consumption Phenomena, Wear, 2008, 265(3–4), p 566–575.

H. Sarmadi, A.H. Kokabi, and S.M. Seyed Reihani, Friction and Wear Performance of Copper-Graphite Surface Composites Fabricated by Friction Stir Processing (FSP), Wear, 2013, 304(1–2), p 1–12.

P. Wu, H.M. Du, X.L. Chen, Z.Q. Li, H.L. Bai, and E.Y. Jiang, Influence of WC Particle Behavior on the Wear Resistance Properties of Ni-WC Composite Coatings, Wear, 2004, 257(1–2), p 142–147.

R.K. Tiwari, J. Yang, M. Saeys, and C. Joachim, Surface Reconstruction of MoS2 to Mo2S3, Surf. Sci., 2008, 602(15), p 2628–2633.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gudala, S., Ramesh, M.R. & Srinath, M.S. Microstructure and Wear Behavior of Self-Lubricating Microwave Clads Deposited on Titanium Alloy. J. of Materi Eng and Perform 31, 8864–8877 (2022). https://doi.org/10.1007/s11665-022-06926-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06926-x