Abstract

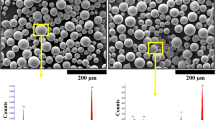

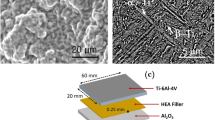

The 3D-structured IN718 surfaces have been designed and printed by SLM for vacuum brazing with BNi2 filler. The effect of brazing temperature and time on microstructure and mechanical property of structured IN718 joints is investigated. The results reveal that the joint consists of ISZ, ASZ, and DAZ, with ISZ consisting of γ solid solution; ASZ consisting of Cr2B, Ni3B Ni3Si, and Ni6Si2B and the intermetallic compounds are concentrated in the crest and trough; DAZ has a large amount of (Cr, Nb, Mo)-rich borides. The different degrees of enrichment of the elements affect the changes of the microstructure and morphology in DAZ. With the increase in brazing temperature, the ASZ gradually becomes smaller, and more Cr2B is observed. At 1110 °C, the reduced isothermal solidification rate leads to the re-formation of intermetallic compounds in the narrower gap zone. With the increase in holding time, the intermetallic compounds gradually decrease to disappear, but in the narrower gap zone, Kirkendall holes appeared. The highest shear strength of the joint is 676.5 MPa along the groove direction and 624.4 MPa in the vertical groove structure direction at 1080 °C/40 min, 27.5 to 38.1% improvement in strength compared with flat joints. The fracture mechanism is mixed with brittle and ductile fracture.

Similar content being viewed by others

References

M.B. Henderson, D. Arrell, R. Larsson, M. Heobel and G. Marchant, Nickel Based Superalloy Welding Practices for Industrial Gas Turbine Applications, Sci. Technol. Weld. Join., 2004, 9(1), p 13–21. https://doi.org/10.1179/136217104225017099

S. Sanchez, P. Smith, Z. Xu, G. Gaspard, C.J. Hyde, W.W. Wits, I.A. Ashcroft, H. Chen and A.T. Clare, Powder Bed Fusion of Nickel-Based Superalloys: A Review, Int. J. Mach. Tools Manuf., 2021, 165, p 103729.

S. Shao, M.M. Khonsari, S. Guo, W.J. Meng and N. Li, Overview: Additive Manufacturing Enabled Accelerated Design of Ni-Based Alloys for Improved Fatigue Life, Additive Manufacturing, 2019, 29, p 100779.

S. Rayapati, Gas Turbine Blade Failure Scenario Due to Thermal Loads in Case of Nickel Based Super Alloys, Mater. Today Proc., 2021, 46, p 8119–26.

G. Zhao, S. Tian, S. Zhang, N. Tian and L. Liu, Deformation and Damage Features of a Re/Ru-Containing Single Crystal Nickel Base Superalloy during Creep at Elevated Temperature, Progress. Natural Sci.: Mater. Int., 2019, 29, p 210–216.

M. Bhuvanesh Kumar and P. Sathiya, Methods and Materials for Additive Manufacturing: A Critical Review on Advancements and Challenges, Thin-Walled Struct., 2021, 159, p 107228. https://doi.org/10.1016/j.tws.2020.107228

D. Zhang, P. Zhang, Z. Liu, Z. Feng, C. Wang and Y. Guo, Thermofluid Field of Molten Pool and Its Effects during Selective Laser Melting (SLM) of Inconel 718 Alloy, Addit. Manuf., 2018, 21(100), p 567–578.

I. Koutiri, E. Pessard, P. Peyre, O. Amlou and T. De Terris, Influence of SLM Process Parameters on the Surface Finish, Porosity Rate and Fatigue Behavior of as-Built Inconel 625 Parts, J. Mater. Process. Technol., 2018, 255, p 536–546. https://doi.org/10.1016/j.jmatprotec.2017.12.043

K.G. Prashanth, R. Damodaram, S. Scudino, Z. Wang, K. Prasad Rao and J. Eckert, Friction Welding of Al–12Si Parts Produced by Selective Laser Melting, Mater. Des., 2014, 57, p 632–637.

H. Yu, F. Li, J. Yang, J. Shao, Z. Wang and X. Zeng, Investigation on Laser Welding of Selective Laser Melted Ti-6Al-4V Parts: Weldability, Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2018, 712, p 20–27.

D. Bridges, C. Ma, Z. Palmer, S. Wang, Z. Feng and A. Hu, Laser Brazing of Inconel® 718 Using Ag and Cu-Ag Nanopastes as Brazing Materials, J. Mater. Process. Technol., 2017, 249, p 313–324. https://doi.org/10.1016/j.jmatprotec.2017.06.010

T. Zaharinie, F. Yusof, M. Hamdi, T. Ariga and R. Moshwan, Effect of Brazing Temperature on the Shear Strength of Inconel 600 Joint, Int. J. Adv. Manuf. Technol., 2014, 73(5), p 1133–1140. https://doi.org/10.1007/S00170-014-5900-X

Y.K. Yu, D.W. Liaw and R.K. Shiue, Infrared Brazing Inconel 601 and 422 Stainless Steel Using the 70Au-22Ni-8Pd Braze Alloy, J. Mater. Sci., 2005, 40(13), p 3445–3452. https://doi.org/10.1007/S10853-005-0446-9

L.X. Zhang, Z. Sun, Q. Xue, M. Lei and X.Y. Tian, Transient Liquid Phase Bonding of IC10 Single Crystal with GH3039 Superalloy Using BNi2 Interlayer: Microstructure and Mechanical Properties, Mater. Des., 2016, 90, p 949–957. https://doi.org/10.1016/j.matdes.2015.11.041

D. Liu, Y. Song, B. Shi, Q. Zhang, X. Song, H. Niu and J. Feng, Vacuum Brazing of GH99 Superalloy Using Graphene Reinforced BNi-2 Composite Filler, J. Mater. Sci. Technol., 2018, 34(10), p 1843–1850. https://doi.org/10.1016/j.jmst.2018.02.008

H. Dong, J. Yang, Y. Xia, Xu, P. Li, C. Dong, J. Chen, N. Liu and L. Zheng, Effect of Cr Content in Ni-Based Amorphous Filler on Microstructure and Shear Strength of K4169 Nickel-Based Alloy Brazed Joint, J. Mater. Process. Technol., 2021, 290, p 116975.

Z.W. Yang, C.L. Wang, Y. Han, Y.T. Zhao, Y. Wang and D.P. Wang, Design of Reinforced Interfacial Structure in Brazed Joints of C/C Composites and Nb by Pre-Oxidation Surface Treatment Combined with in Situ Growth of CNTs, Carbon N. Y., 2019, 143, p 494–506.

W. Guo, T. Gao, Cui, Y. Zhu and P.K. Chu, Interfacial Reactions and Zigzag Groove Strengthening of C/C Composite and Rene N5 Single Crystal Brazed Joint, Ceram. Int., 2015, 41(9), p 11605–11610.

H. Wang, J. Cao and J. Feng, Brazing Mechanism and Infiltration Strengthening of CC Composites to TiAl Alloys Joint, Scr. Mater., 2010, 63(8), p 859–862.

Y. Zhang, G. Zou, L. Liu, A. Wu, Z. Sun and Y.N. Zhou, Vacuum Brazing of Alumina to Stainless Steel Using Femtosecond Laser Patterned Periodic Surface Structure, Mater. Sci. Eng. A, 2016, 662, p 178–184.

S. Periane, A. Duchosal, S. Vaudreuil, H. Chibane, A. Morandeau, M. Anthony Xavior and R. Leroy, Influence of Heat Treatment on the Fatigue Resistance of Inconel 718 Fabricated by Selective Laser Melting (SLM), Mater. Today Proc., 2021, 46, p 7860–7865.

Y. Liu, Q. Guo, C. Li, Y. Mei, Zhou, Y. Huang and H. Li, Recent Progress on Evolution of Precipitates in Inconel 718 Superalloy, Jinshu Xuebao/Acta Metall. Sin., 2016, 52(10), p 1259–1266.

X. Yuan, C. Yun Kang and M.B. Kim, Microstructure and XRD Analysis of Brazing Joint for Duplex Stainless Steel Using a Ni-Si-B Filler Metal, Mater. Charact., 2009, 60(9), p 923–931. https://doi.org/10.1016/j.matchar.2009.03.004

T.B. Massalski, H. Okamoto, P.R. Subramanian and L. Kacprzak, Binary Alloy Phase Diagrams, Alloy Phase Diagrams. T.B. Massalski, J.L. Murray, L.H. Bennett, H. Baker, L. Kacprzak Ed., ASM International, Ohio, 2018, p 89–89

E. Baharzadeh, M. Shamanian, M. Rafiei and H. Mostaan, Properties of IN X-750/BNi-2/SAF 2205 Joints Formed by Transient Liquid Phase Bonding, J. Mater. Process. Technol., 2019, 274, p 116297.

T. Tokunaga, K. Nishio, H. Ohtani and M. Hasebe, Phase Equilibria in the Ni – Si – B System *, Mater. Trans., 2003, 44(9), p 1651–1654.

B. Binesh and A. Jazayeri Gharehbagh, Transient Liquid Phase Bonding of IN738LC/MBF-15/IN738LC Solidification Behavior and Mechanical Properties, J. Mater. Sci. Technol., 2016, 32(11), p 1137–1151. https://doi.org/10.1016/j.jmst.2016.07.017

H. Zhang, C. Li, Q. Guo, Z. Ma, Y. Huang, H. Li and Y. Liu, Hot Tensile Behavior of Cold-Rolled Inconel 718 Alloy at 650 °C: The Role of δ Phase, Mater. Sci. Eng. A, 2018, 722, p 136–146.

A. Łukaszek-Sołek, T. Śleboda, J. Krawczyk, S. Bednarek and M. Wojtaszek, Characterization of the Workability of Ni-Fe-Mo Alloy by Complex Processing Maps, J. Alloys Compd., 2019, 797, p 174–184.

H. Zhang, C. Li, Q. Guo, Z. Ma, H. Li and Y. Liu, Improving Creep Resistance of Nickel-Based Superalloy Inconel 718 by Tailoring Gamma Double Prime Variants, Scr. Mater., 2019, 164, p 66–70.

S.K. Sharma, K. Biswas and J.D. Majumdar, Effect of Heat Input on Mechanical and Electrochemical Properties of Electron-Beam-Welded Inconel 718, J. Mater. Eng. Perform., 2020, 29(3), p 1706–1714. https://doi.org/10.1007/S11665-020-04660-W/TABLES/4

A. Malekan, M. Farvizi, S.E. Mirsalehi, N. Saito and K. Nakashima, Effect of Bonding Temperature on the Microstructure and Mechanical Properties of Hastelloy × Superalloy Joints Bonded with a Ni–Cr–B–Si–Fe Interlayer, J. Manuf. Process., 2019, 47, p 129–140.

F. Jalilian, M. Jahazi and R.A.L. Drew, Microstructural Evolution during Transient Liquid Phase Bonding of Inconel 617 Using Ni-Si-B Filler Metal, Mater. Sci. Eng. A, 2006, 423(1–2), p 269–281.

H. Dong, Y. Xia, Xu, G.J. Naz, Hao, P. Li, J. Zhou and C. Dong, Performance of GH4169 Brazed Joint Using a New Designed Nickel-Based Filler Metal via Cluster-plus-Glue-Atom Model, J. Mater. Sci. Technol., 2020, 39, p 89–98. https://doi.org/10.1016/j.jmst.2019.08.028

L. Sisamouth, M. Hamdi and T. Ariga, Investigation of Gap Filling Ability of Ag-Cu-In Brazing Filler Metals, J. Alloys Compd., 2010, 504(2), p 325–329. https://doi.org/10.1016/j.jallcom.2010.05.129

Q. He, D. Zhu, D. Dong, M. Xu, A. Wang and Q. Sun, Effect of Bonding Temperature on Microstructure and Mechanical Properties during TLP Bonding of GH4169 Superalloy, Appl. Sci., 2019, 9(6), p 1112.

N.P. Wikstrom, A.T. Egbewande and O.A. Ojo, High Temperature Diffusion Induced Liquid Phase Joining of a Heat Resistant Alloy, J. Alloys Compd., 2008, 460(1–2), p 379–385.

Acknowledgments

This research was supported by the National Natural Science Foundation of China (52075317), the Royal Society through International Exchanges 2018 Cost Share (China) scheme (IEC\NSFC\181278), Shanghai Sailing Program (19YF1418100), Shanghai Science and Technology Committee Innovation Grant (17JC1400600, 17JC1400601, 19511106400, 19511106402), Karamay Science and Technology Major Project (2018ZD002B), Aid for Xinjiang Science and Technology Project (2019E0235), Shanghai Local Colleges and Universities Capacity Building Special Plan Project (19030501300), and National Key R & D Program of China (2017YFB1301600).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, N., Shi, H., Zhang, P. et al. Microstructure and Properties of Vacuum-Brazed Joints of 3D-Structured Ni718 High-Temperature Alloy Prepared by Selective Laser Melting. J. of Materi Eng and Perform 31, 7921–7934 (2022). https://doi.org/10.1007/s11665-022-06879-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06879-1