Abstract

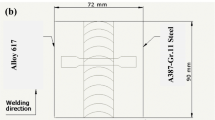

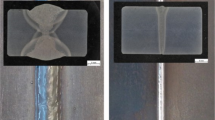

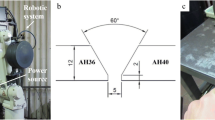

Ultra-high-strength steel significantly contributes to lightweight design. However, it is essential that excellent mechanical properties are maintained after the applied welding process in terms of structural integrity, strength and ductility. This study investigates the microstructural and mechanical properties of metal active gas-welded X-joints of 20-mm-thick S1100 thermomechanically rolled plates with undermatched alform 960 L-MC filler metal. Welding was carried out fully automated in order to obtain uniform properties of the welds for different heat inputs in flat (PA) and vertical up (PF) positions. The mechanical properties of weldments were characterized by hardness, impact and tensile tests and complemented by microstructural analysis using optical and scanning electron microscopy. Different heat inputs due to altered welding positions caused changes in prior austenite grain size and orientation in the weld metal (WM) microstructure which is presented and discussed in detail. The microstructures of the WM consist of ferrite, while the heat-affected zone (HAZ), which was exposed to several thermal cycles, is dominated by bainite and martensite-austenite (M/A) constituents. While in the HAZ the top layer shows fresh martensite of high hardness, the HAZ of filler and root passes was tempered showing lower hardness values. Transverse tensile tests always failed in the weld metal not fulfilling base materials strength requirements. Although the weld metal microstructure consisted of acicular ferrite in PA and PF position, PF weld has lower toughness.

Similar content being viewed by others

References

T.N. Baker, Microalloyed Steels, Ironmak. Steelmak., 2016, 43(4), p 264–307. https://doi.org/10.1179/1743281215Y.0000000063

H. Tasalloti, P. Kah and J. Martikainen, Effect of Heat Input on Dissimilar Welds of Ultra High Strength Steel and Duplex Stainless Steel: Microstructural and Compositional Analysis, Mater. Charact., 2017, 123, p 29–41. https://doi.org/10.1016/j.matchar.2016.11.014

S. Błacha, M.S. Węglowski, S. Dymek and M. Kopyściański, Microstructural and Mechanical Characterization of Electron Beam Welded Joints of High Strength S960QL and Weldox 1300 Steel Grades, Arch. Metall. Mater., 2017, 62(2), p 627–634. https://doi.org/10.1515/amm-2017-0092

M. Mičian, D. Harmaniak, F. Nový, J. Winczek, J. Moravec and L. Trško, Effect of the T8/5 Cooling Time on the Properties of S960MC Steel in the HAZ of Welded Joints Evaluated by Thermal Physical Simulation, Metals, 2020, 10(2), p 18. https://doi.org/10.3390/met10020229

J. Sun, S. Wei and S. Lu, Influence of Vanadium Content on the Precipitation Evolution and Mechanical Properties of High-Strength Fe–Cr–Ni–Mo Weld Metal, Mater. Sci. Eng. A, 2020 https://doi.org/10.1016/j.msea.2019.138739

J. Laitila and J. Larkiola, Effect of Enhanced Cooling on Mechanical Properties of a Multipass Welded Martensitic Steel, Weld. World, 2019, 63(3), p 637–646. https://doi.org/10.1007/s40194-018-00689-7

X.L. Wang, Y.T. Tsai, J.R. Yang, Z.Q. Wang, X.C. Li and C.J. Shang, Effect of Interpass Temperature on the Microstructure and Mechanical Properties of Multi-Pass Weld Metal in a 550-MPa-Grade Offshore Engineering Steel, Weld. World, 2017, 61, p 1155–1168. https://doi.org/10.1007/s40194-017-0498-x

X.L. Wang, Y.R. Nan, Z.J. Xie, Y.T. Tsai, J.R. Yang and C.J. Shang, Influence of Welding Pass on Microstructure and Toughness in the Reheated Zone of Multi-Pass Weld Metal of 550 MPa Offshore Engineering Steel, Mater. Sci. Eng. A, 2017, 702, p 196–205. https://doi.org/10.1016/j.msea.2017.06.081

C. Wen, Z. Wang, X. Deng, G. Wang and R.D.K. Misra, Effect of Heat Input on the Microstructure and Mechanical Properties of Low Alloy Ultra-High Strength Structural Steel Welded Joint, Steel Res. Int., 2018, 89(6), p 1–9. https://doi.org/10.1002/srin.201700500

X. Li, C. Shang, X. Ma, S.V. Subramanian, R.D.K. Misra and J. Sun, Structure and Crystallography of Martensite-Austenite Constituent in the Intercritically Reheated Coarse-Grained Heat Affected Zone of a High Strength Pipeline Steel, Mater. Charact., 2018, 138, p 107–112. https://doi.org/10.1016/j.matchar.2018.01.042

X. Qi, H. Di, X. Wang, Z. Liu, R.D. Misra, P. Huan and Y. Gao, Effect of Secondary Peak Temperature on Microstructure and Toughness in ICCGHAZ of Laser-Arc Hybrid Welded X100 Pipeline Steel Joints, J. Mater. Res. Technol., 2020, 9(4), p 7838–7849. https://doi.org/10.1016/j.jmrt.2020.05.016

W. Guo, Z. Wan, P. Peng, Q. Jia, G. Zou and Y. Peng, Microstructure and Mechanical Properties of Fiber Laser Welded QP980 Steel, J. Mater. Process. Technol., 2018, 256(37), p 229–238. https://doi.org/10.1016/j.jmatprotec.2018.02.015

S. Afkhami, T. Björk and J. Larkiola, Weldability of Cold-Formed High Strength and Ultra-High Strength Steels, J. Constr. Steel Res., 2019, 158, p 86–98. https://doi.org/10.1016/j.jcsr.2019.03.017

M. Amraei, S. Afkhami, V. Javaheri, J. Larkiola, T. Skriko, T. Björk and X.L. Zhao, Mechanical Properties and Microstructural Evaluation of the Heat-Affected Zone in Ultra-High Strength Steels, Thin-Walled Struct., 2020, 157, p 1–11. https://doi.org/10.1016/j.tws.2020.107072

C. Schneider, W. Ernst, R. Schnitzer, H. Staufer, R. Vallant and N. Enzinger, Welding of S960MC with Undermatching Filler Material, Weld. World, 2018, 62(4), p 801–809. https://doi.org/10.1007/s40194-018-0570-1

T. Schaupp, D. Schroepfer, A. Kromm and T. Kannengiesser, Welding Residual Stresses in 960 MPa Grade QT and TMCP High-Strength Steels, J. Manuf. Process., 2017, 27, p 226–232. https://doi.org/10.1016/j.jmapro.2017.05.006

S. Holly, P. Haslberger, D. Zügner, R. Schnitzer and E. Kozeschnik, Development of High-Strength Welding Consumables Using Calculations and Microstructural Characterisation, Weld. World, 2018, 62, p 451–458. https://doi.org/10.1007/s40194-018-0562-1

W. Guo, Q. Liu, J.A. Francis, D. Crowther, A. Thompson, Z. Liu and L. Li, Comparison of Laser Welds in Thick Section S700 High-Strength Steel Manufactured in Flat (1G) and Horizontal (2G) Positions, CIRP Ann. Manuf. Technol., 2015, 64(1), p 197–200. https://doi.org/10.1016/j.cirp.2015.04.070

M. Tümer, F.G. Warchomicka, H. Pahr and N. Enzinger, Mechanical and Microstructural Characterization of Solid Wire Undermatched Multilayer Welded S1100MC in Different Positions, J. Manuf. Process., 2022, 73, p 849–860. https://doi.org/10.1016/j.jmapro.2021.11.021

DIN EN ISO 6892-1, Metallic Materials: Tensile Testing—Part 1: Method to Test at Room Temperature (2016)

DIN EN ISO 148-1, Metallic Materials: Charpy Pendulum İmpact Test—Part 1: Test Method (2009)

Y. Chen, Y. He, H. Chen, H. Zhang and S. Chen, Effect of Weave Frequency and Amplitude on Temperature Field in Weaving Welding Process, Int. J. Adv. Manuf. Technol., 2014, 75(5–8), p 803–813. https://doi.org/10.1007/s00170-014-6157-0

T. Koseki, Solidification and Solidification Structure Control of Weld Metals, Weld. Int., 2002, 16(5), p 347–365. https://doi.org/10.1080/09507110209549544

P. Haslberger, S. Holly, W. Ernst and R. Schnitzer, Microstructure and Mechanical Properties of High-Strength Steel Welding Consumables with a Minimum Yield Strength of 1100 MPa, J. Mater. Sci., 2018, 53(9), p 6968–6979. https://doi.org/10.1007/s10853-018-2042-9

S. Kou, Welding Metallurgy, John Wiley & Sons, Hoboken, NJ, 2003.

S. Kou, Fluid Flow and Solidification in Welding: Three Decades of Fundamental Research at the University of Wisconsin, Weld. J., 2012, 91(11), p 287s–302s.

X. Li, X. Ma, S.V. Subramanian, C. Shang and R.D.K. Misra, Influence of Prior Austenite Grain Size on Martensite-Austenite Constituent and Toughness in the Heat Affected Zone of 700 MPa High Strength Linepipe Steel, Mater. Sci. Eng. A, 2014, 616, p 141–147. https://doi.org/10.1016/j.msea.2014.07.100

L. Lan, X. Kong and C. Qiu, Characterization of Coarse Bainite Transformation in Low Carbon Steel during Simulated Welding Thermal Cycles, Mater. Charact., 2015, 105, p 95–103. https://doi.org/10.1016/j.matchar.2015.05.010

X. Li, C. Shang, X. Ma, B. Gault, S.V. Subramanian, J. Sun and R.D.K. Misra, Elemental Distribution in the Martensite-Austenite Constituent in Intercritically Reheated Coarse-Grained Heat-Affected Zone of a High-Strength Pipeline Steel, Scr. Mater., 2017, 139, p 67–70. https://doi.org/10.1016/j.scriptamat.2017.06.017

Q. Sun, H.S. Di, J.C. Li, B.Q. Wu and R.D.K. Misra, A Comparative Study of the Microstructure and Properties of 800 MPa Microalloyed C-Mn Steel Welded Joints by Laser and Gas Metal Arc Welding, Mater. Sci. Eng. A, 2016, 669, p 150–158. https://doi.org/10.1016/j.msea.2016.05.079

Y. You, C. Shang, L. Chen and S. Subramanian, Investigation on the Crystallography of the Transformation Products of Reverted Austenite in Intercritically Reheated Coarse Grained Heat Affected Zone, Mater. Des., 2013, 43, p 485–491. https://doi.org/10.1016/j.matdes.2012.07.015

X. Wang, Z. Wang, Z. Xie, X. Ma, S. Subramanian, C. Shang, X. Li and J. Wang, Combined Effect of M/A Constituent and Grain Boundary on the Impact Toughness of CGHAZ and ICCGHAZ of E550 Grade Offshore Engineering Steel, Math. Biosci. Eng., 2019, 16(6), p 7494–7509. https://doi.org/10.3934/mbe.2019376

M. Pirinen, The Effects of Welding Heat Input on the Usability of High Strength Steels in Welded Structures. Doctor of Science Thesis. Lappeenranta University of Technology (2013)

A. Lambert, J. Drillet, A.F. Gourgues, T. Sturel and A. Pineau, Microstructure of Martensite ± Austenite Constituents in Heat Affected Zones of High Strength Low Alloy Steel Welds in Relation to Toughness Properties, Sci. Technol. Weld. Join., 2000, 5(3), p 168–173. https://doi.org/10.1179/136217100101538164

N. Huda, A.R.H. Midawi, J. Gianetto, R. Lazor and A.P. Gerlich, Influence of Martensite-Austenite (MA) on Impact Toughness of X80 Line Pipe Steels, Mater. Sci. Eng. A, 2016, 662, p 481–491. https://doi.org/10.1016/j.msea.2016.03.095

X.L. Wang, X.M. Wang, C.J. Shang and R.D.K. Misra, Characterization of the Multi-Pass Weld Metal and the Impact of Retained Austenite Obtained through Intercritical Heat Treatment on Low Temperature Toughness, Mater. Sci. Eng. A, 2016, 649, p 282–292. https://doi.org/10.1016/j.msea.2015.09.030

P. Mohseni, J.K. Solberg, M. Karlsen, O.M. Akselsen and E. Østby, Investigation of Mechanism of Cleavage Fracture Initiation in Intercritically Coarse Grained Heat Affected Zone of HSLA Steel, Mater. Sci. Technol., 2012, 28(11), p 1261–1268.

M. Tümer, J. Domitner and N. Enzinger, Electron Beam and Metal Active Gas Welding of Ultra-High-Strength Steel S1100MC: Influence of Heat Input, Int. J. Adv. Manuf. Technol., 2021 https://doi.org/10.1007/s00170-021-08055-6

X. Li, X. Ma, S.V. Subramanian, C. Shang and R.D.K. Misra, Influence of Prior Austenite Grain Size on Martensite-Austenite Constituent and Toughness in the Heat Affected Zone of 700 MPa High Strength Linepipe Steel, Mater. Sci. Eng. A, 2014, 616, p 141–147. https://doi.org/10.1016/j.msea.2014.07.100

W. Guo, L. Li, S. Dong, D. Crowther and A. Thompson, Comparison of Microstructure and Mechanical Properties of Ultra-Narrow Gap Laser and Gas-Metal-Arc Welded S960 High Strength Steel, Opt. Lasers Eng., 2017, 91, p 1–15. https://doi.org/10.1016/j.optlaseng.2016.11.011

Z. Jiang, L. Ren, J. Huang, X. Ju, H. Wu, Q. Huang and Y. Wu, Microstructure and Mechanical Properties of the TIG Welded Joints of Fusion CLAM Steel, Fusion Eng. Des., 2010, 85(10–12), p 1903–1908. https://doi.org/10.1016/j.fusengdes.2010.06.019

W. Maurer, W. Ernst, R. Rauch, R. Vallant and N. Enzinger, Evaluation of the Factors Influencing the Strength of HSLA Steel Weld Joint with Softened HAZ, Weld. World, 2015, 59(6), p 809–822.

H. Zhao and E.J. Palmiere, Effect of Austenite Grain Size on Acicular Ferrite Transformation in a HSLA Steel, Mater. Charact., 2018, 145, p 479–489. https://doi.org/10.1016/j.matchar.2018.09.013

Acknowledgment

Base materials and filler wire were provided by Voestalpine Stahl Linz and Voestalpine Böhler Welding, respectively. Mustafa Tümer is supported by The Scientific and Technological Research Council of Turkey (TUBITAK) under the 2219 International Postdoctoral Research Scholarship Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited submission to the Journal of Materials Engineering and Performance selected from presentations at the symposium “Joining,” belonging to the area “Processing” at the European Congress and Exhibition on Advanced Materials and Processes (EUROMAT 2021), held virtually from September 12–16, 2021, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Tümer, M., Vallant, R., Warchomicka, F.G. et al. Undermatched Welding of Ultra-High-Strength Steel S1100 with Metal-Cored Wire: Influence of Welding Positions on Mechanical Properties. J. of Materi Eng and Perform 31, 7068–7079 (2022). https://doi.org/10.1007/s11665-022-06876-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06876-4