Abstract

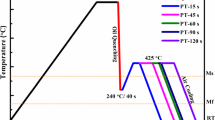

The effects of different partitioning temperatures and time on the microstructure and properties of Mn-Si-Cr alloy steel were investigated. The results showed that with the increase in the partitioning temperature or the extension of the partitioning time, the martensite arrangement in the Mn-Si-Cr alloy steel became irregular, and the boundary was gradually blurred; the austenite mainly existed in the form of thin film, and the austenite content increased at first and then decreased gradually. When the partitioning temperature was too high or the partitioning time was too long, all led to the decomposition of austenite into low-carbon bainite and carbides. With the increase in the temperature, the hardness of the samples decreased gradually, the wear weight loss increased gradually, and the impact toughness increased linearly. With the extension of the partitioning time, the hardness of the sample gradually decreased. When the partitioning time is 5-10min, the hardness decreases greatly. When the partitioning temperature was 350 °C and the partitioning time was 60s, the test steel can have hardness, impact toughness, and wear resistance and has good comprehensive mechanical properties.

Similar content being viewed by others

References

J.M. Tong, Research Progress of Wear Resistant Steel, Huadian Technol., 2003, p 29–32+40.

X.J. Yang, M. Bai, D.Y. Zhang, Y. Li, Y.Q. Lv and Z.W. Liu, Research Status of Wear Resistant Steel, Hot Working Technol., 2021, 50, p 7–10.

S.Z. Wei and L.J. Xu, Research Progress of Wear-Resisting Materials of Steel, Acta Metall. Sin. (chin. Ed.), 2020, 56, p 523–538.

J.M. Hou, Manufacturing Process and Performance Analysis of New High Manganese Steel Lining Plate, Taiyuan University of Science and Technology, 2014.

G.M. Sorokin and S.N. Bobrov, Fundamental Principles for Choosing Steels on the Basis of Results of Wear Tests, Met. Sci. Heat Treat, 1998, 40, p 76–78.

G.M. Sorokin and V.N. Malyshev, Steel’s Wear Resistance Definition Method by their Standard Mechanical Characteristics, Tribol. Int., 2008, 41, p 515–523.

G.M. Sorokin and V.N. Malyshev, Influence of the Mechanical Characteristics of Steel on the Abrasive Wear and Frictional Coefficient, Russ. Eng. Res., 2008, 28, p 935–938.

L. Liang, X.T. Deng, K.M. Wu, S.D. Wang and G.H. Li, Study on Erosion Wear Properties of Low alloy high Strength Wear Resistant Steel, Steel Rolling, 2018, 35, p 10–16.

D.K. Matlock, V.E. Brautigam and J.G. Speer, Application of the Quenching and Partitioning (Q&P) Process to a Medium-carbon, High-Si Microalloyed bar steel, Thermec’2003, Pts, 2003, 1–5(426), p 1089–1094.

R. Ding, D. Tang, A.M. Zhao, R. Dong, J.Y. Cheng and X. Meng, Effect of Intercritical Temperature on Quenching and Partitioning Steels Originated from Martensitic Pre-Microstructure, J. Mater. Res., 2014, 29, p 2525–2533.

I. Miettunen, S. Ghosh, M.C. Soman, S. Pallaspuro and J. Komi, Competitive Mechanisms Occurring during Quenching and Partitioning of Three Silicon Variants of 0.4 wt.% Carbon Steels, J. Mater. Res. Technol, 2021, 11, p 1045–1060.

L. Wang and J.G. Speer, Quenching and Partitioning Steel Heat Treatment, Metallography, Microstructure, and Analysis, 2013, 2, p 268–281.

L.P. Ding, Effect of Q&P Heat Treatment Process on Microstructure and Properties of Low Alloy Wear Resistant Steel, Zhengzhou university, 2013.

J.P. Lai, J.X. Yu and J. Wang, Effect of Quenching-Partitioning Treatment on the Microstructure, Mechanical and Abrasive Properties of High Carbon Steel, Int. J. Miner. Metall. Mater., 2021, 28, p 676–687.

P.G.B.D. Oliveira, R.T.J. Aureliano, L.C. Casteletti, A.I. Filho, A.L. Neto and G.E. Totten, Effect of Low-Temperature Austempering and Quenching and Partitioning Treatments on Adhesive Wear Resistance of High-Silicon Multiphase Steels, J. Mater. Eng. Perform, 2020, 29, p 3542–3550.

H.Y. Dong, K.M. Wu, X.L. Wang, T.P. Hou and R. Yan, A Comparative Study on the Three-body Abrasive Wear Performance of Q&P Processing and Low-Temperature Bainitic Transformation for a Medium-Carbon Dual-Phase Steel, Wear, 2018, 402, p 21–29.

V.G. Efremenko, V.I. Zurnadzhi, Yu.G. Chabak, O.V. Tsvetkova and A.V. Dzherenova, Application of the Q-n-P-Treatment for Increasing the Wear Resistance of Low-Alloy Steel with 0.75% C, Mater. Sci, 2017, 53, p 129–129.

V.I. Zurnadzhy, V.G. Efremenko, M.N. Brykov, I. Petryshynets, T.V. Pastukhova and R.A. Kussa, The Metastability of Retained Austenite in Multiphase Steel during Abrasive Wear, J. Frict. Wear, 2020, 41, p 119–124.

P.P. Acharya and R. Bhat, Structure-Property Correlation of Quenching and Partitioning Heat Treated Silicon-Manganese Steel, Silicon, 2019, 11, p 1525–1535.

W. Zhou, Microstructure regulation and dynamic mechanical properties of medium-carbon micro-nano bainitic steel. Wuhan University of Science and Technology, 2019.

A.J. Clarke, J.G. Speer, M.K. Miller, R.E. Hackenberg, D.V. Edmonds, F.C. Rizzo and M.E. De, Carbon Partitioning to Austenite from Martensite or Bainite during the Quench and Partition (Q&P) Process: a Critical Assessment, Acta Mater, 2008, 56, p 16–22.

N. Zhong, Study on high Strength Q&P steel and Q-P-T steel, Shanghai Jiao Tong University, 2009.

J. Li, Effect of Q&P process on microstructure and properties of low alloy wear resistant steel, Wuhan University of Science and Technology, 2019.

P.F. Gao, Study on microstructure control and deformation mechanism of 1300MPa Grade Quenched partitioned steel, University of Science and Technology Beijing, 2021.

C.L. Zhang, S.H. Li, H.G. Fu and Y.H. Lin, Microstructure Evolution and Wear Resistance of High Silicon Bainitic Steel after Austempering, J. Mater. Res. Technol, 2020, 9, p 4826–4839.

C.L. Zhang, H.G. Fu, S.Q. Ma, J. Lin and Y.P. Lei, Microstructure and Properties of High-Si high-Mn bainitic Steel after Heat Treatment, Mater. Res. Express, 2019, 6, p 08658.

R.M. Wu, Study on the correlation between toughness and microstructure evolution of High strength sheet steel treated by Q&P, Shanghai Jiao Tong University, 2015.

Y.G. Deng, H.S. Di and R.D.K. Misra, Microstructure and Mechanical Property Relationship in a High Strength High-Al Low-Si Hot-Dip Galvanized Steel Under Quenching and Partitioning Process, J. Mater. Res. Technol, 2020, 9, p 14401–14411.

N. Zhong, X.D. Wang, Y.H. Rong and L. Wang, Interface Migration Between Martensite and Austenite during Quenching and Partitioning (Q&P) Process, J. Mater. Sci. Technol., 2006, 22, p 751–754.

X. Lin, Study on shape evolution of Q&P high strength steel sheet during heat treatment, University of Science and Technology Beijing, 2018.

Acknowledgment

The authors would like to thank the financial support for this work from Hebei Science and Technology Major Project (21281003Z) and National Natural Science Foundation of China (52075010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Si, Z., Yuan, N. & Fu, H. Effect of Quenching and Partitioning Process on Microstructure and Properties of Mn-Si-Cr Steel. J. of Materi Eng and Perform 31, 8655–8667 (2022). https://doi.org/10.1007/s11665-022-06871-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06871-9