Abstract

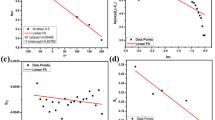

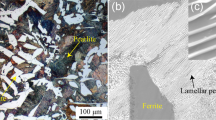

The modified Zerilli–Armstrong (mZ-A) model, optimized Zerilli–Armstrong (oZ-A) model, modified Johnson–Cook model, double multiple nonlinear regression (DMNR) model, and BP artificial neural network (BPANN) model were all used to compare the hot deformation behavior of EA4T steel in this paper. The Gleeble-3800 simulator was used to conduct thermal compression tests. The deformation temperature range was 1243~1443 K, the strain rate range was 0.01~1/s and the true strain was 0.8. The obtained stress–strain experimental data were used to calculate the material constants for the five constitutive models, and the established constitutive model was then thoroughly evaluated using the correlation coefficient (R), average absolute error (AARE), root-mean-square error (RMSE), and relative error statistical results (RESR). The experimental results showed that the R value of the mZ-A model is 0.9880, the AARE value is 6.6550%, the RMSE value is 5.8777 MPa, the variation range of the RESR value is − 40.3496 ~ 21.7640%, and the average value is 1.3098%. The mZ-A model cannot adequately depict the high temperature flow behavior of EA4T steel when compared to the other four models. With an R value of 0.9996, an AARE value of 1.1630%, an RMSE value of 1.0358 MPa, a variation range of 12.9101 to 10.3263%, and an average value of 0.0070%, the trained BPANN model has the best prediction performance. The other three models' predictions are in good agreement with the experimental results. The oZ-A model, however, can more accurately follow the deformation behavior of EA4T steel at high temperatures than the other two models. Therefore, when the physical situation of a material response needs to be known, the oZ-A model can be used.

Similar content being viewed by others

References

W.-J. Chen, Q.-Y. Chen, Y. Mao and S.-C. Tang, Effect of Laser Cladding on Microstructural Transformation and Mechanical Properties of Heat Affected Zone of EA4T Steel[J], Mater. Exp., 2021, 11(10), p 1707–1715.

D. Li, Z. Zhu, S. Xiao, G. Zhang and Y. Lu, Plastic Flow Behavior Based on Thermal Activation and Dynamic Constitutive Equation of 25CrMo4 Steel During Impact Compression[J], Mater. Sci. Eng. A, 2017, 707, p 459–465.

S. Fintova, P. Pokorny, R. Fajkos and P. Hutar, EA4T Railway Axle Steel Fatigue Behavior Under Very High-Frequency Fatigue Loading[J], Eng. Failure Anal., 2020 https://doi.org/10.1016/j.engfailanal.2020.104668

L.-M. Kang, M. Lei, J. Zou, Y.-L. Liang and X.-P. Tang, The Influence of Circulation Quenching on Temper Brittleness of Steel EA4T[J], Adv. Mater. Res., 2012 https://doi.org/10.4028/www.scientific.net/AMR.463-464.712

P. Pokorny, L. Nahlik and P. Hutar, Influence of Variable Stress Ratio During Train Operation on Residual Fatigue Lifetime of Railway Axles[J], Proc. Struct. Integr., 2016, 2, p 3585–3592.

X. Zhao, S. Wu, J. Bao, N. Ao, W. Peng and W. Sun, Experimental Characterization and Numerical Modeling on External Impacting of High-Speed Railway Axle EA4T Steel[J], Eng. Fail. Anal., 2021 https://doi.org/10.1016/j.engfailanal.2021.105449

Y.-C. Lin and X.-M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working[J], Mater. Des., 2011, 32(4), p 1733–1759.

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura and J.-J. Jonas, Dynamic and Post-Dynamic Recrystallization Under Hot, Cold and Severe Plastic Deformation Conditions[J], Prog. Mater Sci., 2014, 60(1), p 130–207.

Y. Xu, Y. Zhang, X. Zhuang, Z. Cao, Y. Lu and Z. Zhao, Numerical Modeling and Anvil Design of High-Speed Forging Process for Railway Axles[J], Int.J. Mater. Form., 2021, 14, p 813–832.

G. Su, Z. Yun, Y.C. Lin, D.G. He, S. Zhang and Z.J. Chen, Microstructure Evolution and a Unified Constitutive Model of Ti-55511 Alloy Compressed at Stepped Strain Rates[J], Materials, 2021, 14, p 6750. https://doi.org/10.3390/ma14226750

Z.J. Chen, Y.C. Lin, D.G. He, Y.M. Lou and M.S. Chen, A Unified Dislocation Density-Based Model for an Aged Polycrystalline Ni-Based Superalloy Considering the Coupled Effects of Complicate Deformation Mechanisms and Initial δ Phase[J], Mater. Sci. Eng., 2021, 827, p 142062. https://doi.org/10.1016/j.msea.2021.142062

Y.Q. Jiang, Y.C. Lin, G.Q. Wang, G.D. Pang, M.S. Chen and Z.C. Huang, Microstructure Evolution and a Unified Constitutive Model for a Ti-55511 Alloy Deformed in β Region[J], J. Alloy. Compd., 2021, 870, 159534. https://doi.org/10.1016/j.jallcom.2021.159534

I.-J. Beyerlein and C. Tomé, A Dislocation-Based Constitutive Law for Pure Zr Including Temperature Effects[J], Int. J. Plast, 2008, 24(5), p 867–895.

H.-Y. Li, J.-D. Hu, D.-D. Wei, X.-F. Wang and Y.-H. Li, Artificial Neural Network and Constitutive Equations to Predict the Hot Deformation Behavior of Modified 2.25Cr–1Mo Steel[J], Mater. Des., 2012, 42, p 192–197.

S.-H. Song, A Comparison Study of Constitutive Equation, Neural Networks, and Support Vector Regression for Modeling Hot Deformation of 316L Stainless Steel[J], Materials, 2020 https://doi.org/10.3390/ma13173766

J. Cai, K. Wang and Y. Han, A Comparative Study on Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict High-Temperature Flow Behavior of Ti–6Al–4V Alloy in α + β Phase[J], High Temp. Mater. Processes (London), 2016, 35(3), p 297–307.

Y. Liu, L.-I. Ming, X.-W. Ren, Z.-B. Xiao and Y.-C. Huang, Flow Stress Prediction of Hastelloy C-276 Alloy Using Modified ZerilliArmstrong, JohnsonCook and Arrhenius-Type Constitutive Models[J], Trans. Nonferrous Metals Soc. China, 2020, 30(11), p 3031–3042.

G. Xu, L. Wang, S. Li and L. Wang, Hot Deformation Behavior of EA4T Steel[J], Acta Metall. Sinica, 2012, 25(5), p 374–382.

P. Zhou and Q.-X. Ma, Dynamic Recrystallization Behavior and Processing Map Development of 25CrMo4 Mirror Plate Steel During Hot Deformation[J], Acta Metall. Sinica, 2017, 30, p 907–920.

Y.-M. Huo, Q. Bai, B. Wang, J. Lin and J. Zhou, A New Application of Unified Constitutive Equations for Cross Wedge Rolling of a High-Speed Railway Axle Steel[J], J. Mater. Process. Technol., 2015, 223, p 274–283.

Z. Zhu, Y. Lu, Q. Xie, D. Li and N. Gao, Mechanical Properties and Dynamic Constitutive Model of 42CrMo Steel[J], Mater. Des., 2017, 119, p 171–179.

Y.C. Lin, M.S. Chen and J. Zhong, Constitutive Modeling for Elevated Temperature Flow Behavior of 42CrMo Steel, Comput[J], Mater. Sci, 2008, 42, p 470–477. https://doi.org/10.1016/j.commatsci.2007.08.011

Y.-M. Huo, B.-Y. Wang and J.-G. Lin, Development of Constitutive Model of EA4T High-Speed Train Shaft Steel Based on Internal-State-Variable Method[J], Appl. Mech. Mater., 2012, 189, p 31–35.

W. Wang, J. Zhao, R.-X. Zhai and R. Ma, Arrhenius-Type Constitutive Model and Dynamic Recrystallization Behavior of 20Cr2Ni4A Alloy Carburizing Steel[J], Steel Res. Int., 2017 https://doi.org/10.1002/srin.201600196

G. Ji, F. Li, Q. Li, H. Li and Z. Li, Prediction of the Hot Deformation Behavior for Aermet100 Steel Using an Artificial Neural network[J], Comput. Mater. Sci., 2010, 48(3), p 626–632.

X. Xiao, G.-Q. Liu, B.-F. Hu, X. Zheng, L.-N. Wang, S.-J. Chen and A. Ullah, A Comparative Study on Arrhenius-Type Constitutive Equations and Artificial Neural Network Model to Predict High-Temperature Deformation Behaviour in 12Cr3WV Steel[J], Comput. Mater. Sci., 2012, 62, p 227–234.

D. Samantaray, S. Mandal and A.-K. Bhaduri, A Comparative Study on Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict Elevated Temperature Flow Behaviour in Modified 9Cr-1Mo Steel[J], Comput. Mater. Sci., 2009 https://doi.org/10.1016/j.commatsci.2009.09.025

D. Samantaray, S. Mandal, U. Borah, A.-K. Bhaduri and P.-V. Sivaprasad, A Thermo-Viscoplastic Constitutive Model to Predict Elevated-Temperature Flow Behaviour in a Titanium-Modified Austenitic Stainless Steel[J], Mater. Sci. Eng. A, 2009, 526, p 1–6.

L. Quan and J.-Z. Yang, Prediction of High Temperature Flow Stress of AZ80 Magnesium Alloy by Using Modified and Optimized Zerilli-Armstrong Constitutive Models [J], Chin. J. Nonferrous Metals, 2021, 31(8), p 2091–2100.

Y.C. Lin, L.T. Li, Y.X. Fu and Y.Q. Jiang, Hot Compressive Deformation Behavior of 7075 Al Alloy Under Elevated Temperature[J], J. Mater. Sci, 2012, 47, p 1306–1318. https://doi.org/10.1007/s10853-011-5904-y

Y.-C. Lin, X.-M. Chen and G. Liu, A Modified Johnson-Cook Model for Tensile Behaviors of Typical High-Strength Alloy Steel[J], Mater. Sci. Eng. A, 2010, 527(26), p 6980–6986.

Z. Yuan, F. Li, H. Qiao, M. Xiao, J. Cai and J. Li, A modified constitutive equation for elevated temperature flow behavior of Ti–6Al–4V alloy based on double multiple nonlinear regression[J], Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 2013, 578, p 260–270.

O.-A. BhekisiphoTwala, Constitutive Modelling of INCONEL 718 Using Artificial Neural Network[J], IOP Conf. Series Mater. Sci. Eng., 2017 https://doi.org/10.1088/1757-899X/225/1/012054

M. Ahmed, M. Anastasia, K. Anton, P. Theo, A. Sergey, K. James and P. Vladimir, Modelling of the Superplastic Deformation of the Near-α Titanium Alloy (Ti-2.5Al-1.8Mn) Using Arrhenius-Type Constitutive Model and Artificial Neural Network[J], Metals, 2017, 7, p 568–568.

L.F. Guo and L.I. Bao-Cheng, Constitutive relationship model of TC21 alloy based on artificial neural network[J], Trans. Nonferrous Metals Soc. China, 2013 https://doi.org/10.1016/S1003-6326(13)62658-8

A. Saxena, A. Kumaraswamy, N. Kotkunde and K. Suresh, Constitutive Modeling of High-Temperature Flow Stress of Armor Steel in Ballistic Applications: A Comparative Study[J], J. Mater. Eng. Perform., 2019, 28(10), p 6505–6513.

A. Rudra, M. Ashiq, S. Das and R. Dasgupta, Constitutive Modeling for Predicting High-Temperature Flow Behavior in Aluminum 5083+10WtPct SiC p Composite[J], Metall. Mater. Trans. B, 2019 https://doi.org/10.1007/s11663-019-01531-1

M.L. Shen, Y.M. Huo, T. He, X. Yong and J.X. Xing, Comparison of Two Constitutive Modelling Methods in Application of TC16 Alloy at the Elevated Deformation Temperature[J], Mater. Today Commun., 2020, 24, p 101053.

A. Rudra, S. Das and R. Dasgupta, J. Mater. Eng. Perform., 2019, 28, p 87–99. https://doi.org/10.1007/s11665-018-3813-9

G.Z. Quan, Z.H. Zhang, Y.T. Zhou, T. Wang and Y.F. Xia, Numerical Description of Hot Flow Behaviors at Ti-6Al-2Zr-1Mo-1V Alloy By GA-SVR and Relative Applications[J], Mater. Res., 2016, 19(6), p 1253–1269.

H. Ahmadi, H. Ashtiani and M. Heidari, A Comparative Study of Phenomenological, Physically-Based and Artificial Neural Network Models to Predict the Hot Flow Behavior of API 5CT-L80 Steel[J], Mater. Today Commun., 2020, 25, p 101528.

Z. Yuan, F. Li, H. Qiao, M. Xiao, J. Cai and L. Jiang, A Modified Constitutive Equation for Elevated Temperature Flow Behavior of Ti–6Al–4V Alloy Based on Double Multiple Nonlinear Regression[J], Mater. Sci. Eng. Struct. Mater. Prop. Microst. Process., 2013, 578(20), p 260–270.

Z. Yuan, F. Li, G. Ji, H. Qiao and J. Li, Flow Stress Prediction of SiCp/Al Composites at Varying Strain Rates and Elevated Temperatures[J], J. Mater. Eng. Perform., 2014, 23(3), p 1016–1027.

N. Neethu, N.A. Hassan, R.R. Kumar, P. Chakravarthy, A. Srinivasan and A.M. Rijas, Comparison of Prediction Models for the Hot Deformation Behavior of Cast Mg–Zn–Y Alloy[J], Trans. Indian Inst. Met., 2020, 73(6), p 1619–1628.

Acknowledgment

This work was support by National key research and development plan funding (Grant No. 2018YFB1307900).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bai, J., Huo, Y., He, T. et al. Comparison of Five Different Models Predicting the Hot Deformation Behavior of EA4T Steel. J. of Materi Eng and Perform 31, 8169–8182 (2022). https://doi.org/10.1007/s11665-022-06828-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06828-y