Abstract

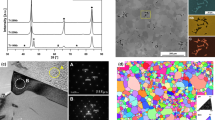

Isothermal compression tests with different conditions were performed on an as-extruded WZ-A3 alloys with different level of boron and carbon. The results show that low angle grain boundaries (LAGBs) and γ′ phases with diameter greater than 300 nm increase rapidly and Σ3 twin boundaries (TBs) decrease after hot compression deformation at lower temperature for as-extruded alloys. In addition, compared to that of as-extruded state, the grains are refined after hot compression as the compression temperature decreases. The HB\C sample (alloy with higher B and C content) has more LAGBs and less TBs as well as lower complete recrystallization zone fraction compared with those for the LB\C sample (alloy with lower B and C content) for all the same compression conditions performed. Furthermore, under all identical compression conditions performed, the HB\C sample shows a higher peak stress (σp) than that of the LB\C sample. The HB\C sample has larger area fraction and smaller average size of γ′ phases (>300 nm) than that of the LB\C sample for all the same compression conditions performed. Hence, more γ′ particles (>300 nm) in HB\C have larger average inhibition force for boundaries migration compared with that in LB\C during hot compression deformation. The area fraction of γ′ phase (>300 nm) decreases with increasing of deformation temperatures and shows different variation characteristic with small amplitude decreasing of strain rate at different constant deformation temperatures. More γ′ phases exist in samples compressed at lower temperature, inhibiting dynamic recrystallization (DRX) behavior. In addition, the dissolution rate of fine γ′ phases is faster in the LB\C sample than that in the HB\C sample especially at 1100 °C compression temperature. Boron mainly stabilizes γ′ phases by inhibiting diffusion of solute atoms (Al, Ti) during hot compression and carbon mainly contributes to the precipitation of carbides. Continuous DRX (CDRX) and discontinuous DRX (DDRX) both happen during hot compression for the as-extruded WZ-A3 alloy.

Similar content being viewed by others

References

G.A. He, F. Liu, J.Y. Si, C. Yang and L. Jiang, Characterization of Hot Compression Behavior of a New HIPed Nickel-Based P/M Superalloy Using Processing Maps, Mater. Des., 2015, 87, p 256–265.

S.L. Semiatin, K.E. Mcclary, A.D. Rollett, C.G. Roberts, E.J. Payton, F. Zhang and T.P. Gabb, Plastic Flow and Microstructure Evolution During Thermomechanical Processing of a PM Nickel-Base Superalloy, Metall. Mater. Trans. A, 2013, 44A, p 2778–2798.

Y.H. Liu, Y.Q. Ning, Z.K. Yao, H. Li, X.P. Miao, Y.Z. Li and Z.L. Zhao, Plastic Deformation and Dynamic Recrystallization of a Powder Metallurgical Nickel-Based Superalloy, J. Alloys Compd., 2016, 675, p 73–80.

Y.H. Wang, Y. Li, H. Zhang and J.Z. Guo, Hot Deformation Induced Microstructure Evolution of a Novel as-Extruded Ni-Based P/M Superalloy, Philos. Mag., 2021, 101, p 193–210.

D.Y. Cai, L.Y. Xiong, W.C. Liu, G.D. Sun and M. Yao, Characterization of Hot Deformation Behavior of a Ni-Base Superalloy Using Processing Map, Mater. Des., 2009, 30(3), p 921–925.

X. Huang, M.C. Chaturvedi, N.L. Richards and J. Jackman, The Effect of Grain Boundary Segregation of Boron in Cast Alloy 718 on HAZ Microfissuring—A SIMS Analysis, Acta Mater., 1997, 45(8), p 3095–3107.

J.S.C. Jang, C.J. Ou and C.Y. Cheng, The Evolution of Microstructure Change and Mechanical Properties for a Nickel Silicide Based Alloy Doped with Carbon and Boron, Mater. Sci. Eng. A, 2002, 329(SI), p 455–460.

T.J. Garosshen, T.D. Tillman and G.P. Mccarthy, Effects of B, C, and Zr on the Structure and Properties of a P/M Nickel Base Superalloy, Metall. Trans. A, 1987, 18, p 69–77.

X.X. Li, M.Q. Ou, M. Wang, L. Zhang, Y.C. Ma and K. Liu, Effect of Boron Addition on the Microstructure and Mechanical Properties of K4750 Nickel-Based Superalloy, J. Mater. Sci. Technol., 2021, 60(4), p 177–185.

G.M. Bond, I.M. Robertson and H.K. Birnbaum, Effect of Boron on the Mechanism of Strain Transfer Across Grain Boundaries in Ni3Al, J. Mater. Res., 1987, 2, p 436–440.

H. Ershadiki, G. Ebrahimi, H. Ezatpour and A. Momeni, Effect of Boron on the Microstructure Evolution and Dynamic Recrystallization Kinetics of Allvac718plus Superalloy, J. Mater. Eng. Perform., 2021, 30(1), p 212–227.

J.A. Brusso and D.E. Mikkola, Effects of Boron on the Deformation Behavior of Ni3Al, J. Mater. Res., 1994, 9(7), p 1742–1754.

C.T. Liu, C.L. White and J.A. Horton, Effect of Boron on Grain-Boundaries in Ni3Al, Acta Metall., 1985, 33(2), p 213–229.

B.P. Wu, L.H. Li, J.T. Wu, Z. Wang, Y.B. Wang, X.F. Chen, J.X. Dong and J.T. Li, Effect of Boron Addition on the Microstructure and Stress-Rupture Properties of Directionally Solidified Superalloys, Int. J. Miner. Metall. Mater., 2014, 21(11), p 1120–1126.

B. Ladna and H.K. Birnbaum, Surface and Grain Boundary Segregation of Sulfur and Boron in Nickel, Acta Metall., 1988, 36(3), p 745–755.

A.V. Shulga, Boron and Carbon Behavior in the Cast Ni-Base Superalloy EP962, J. Alloys Compd., 2007, 436(1–2), p 155–160.

R.T. Holt and W. Wallace, Impurities and Trace Elements in Nickel-Base Superalloys, Int. Met. Rev., 1976, 21(1), p 1–24.

H. Jiang, C. Liu, J.X. Dong and M.C. Zhang, The Effect of Mo and Ti Elements on Long-Term Microstructure Stability of 617B Nickel-Base Superalloy, J. Alloys Compd., 2020, 821, p 1–11.

P.J. Zhou, J.J. Yu, X.F. Sun, H.R. Guan and Z.Q. Hu, The Role of Boron on a Conventional Nickel-Based Superalloy, Mater. Sci. Eng. A, 2008, 491(1–2), p 159–163.

X.R. Tian and Y.T. Chou, Grain Boundary Ssoftening in Boron-Doped Ni3Al, MRS Proc., 1988, 122, p 311–316.

H. Jiang, J.X. Dong, M.C. Zhang and Z.H. Yao, A Study on the Effect of Strain Rate on the Dynamic Recrystallization Mechanism of Alloy 617B, Metall. Mater. Trans. A, 2016, 47(10), p 5071–5087.

Y. Cao, H.S. Di, J.Q. Zhang, J.C. Zhang, T.J. Ma and R.D.K. Misra, An Electron Backscattered Diffraction Study on the Dynamic Recrystallization Behavior of a Nickel–Chromium Alloy (800H) During hot Deformation, Mater. Sci. Eng. A, 2013, 585, p 71–85.

Q.M. Guo, D.F. Li, S.L. Guo, H.J. Peng and J. Hu, The Effect of Deformation Temperature on the Microstructure Evolution of Inconel 625 Superalloy, J. Nucl. Mater., 2011, 414(3), p 440–450.

D.F. Li, Q.M. Guo, S.L. Guo, H.J. Peng and Z.G. Wu, The Microstructure Evolution and Nucleation Mechanisms of Dynamic Recrystallization in Hot-Deformed Inconel 625 Superalloy, Mater. Des., 2011, 32(2), p 696–705.

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang and L.T. Li, EBSD Study of a Hot Deformed Nickel-Based Superalloy, J. Alloys Compd., 2015, 640, p 101–113.

E. Cadel, D. Lemarchand, S. Chambreland and D. Blavette, Atom Probe Tomography Investigation of the Microstructure of Superalloys N18, Acta Mater., 2002, 50(5), p 957–966.

L. Wang, G. Xie and L.H. Lou, Effect of Carbon Content on the Recrystallization of a Single Crystal Nickel-Based Superalloy, Mater. Lett., 2013, 109, p 154–157.

L. Qin, Y.L. Pei, S.S. Li, X.B. Zhao, S.K. Gong and H.B. Xu, Effect of Thermal Stability of γ′ Phase on the Recrystallization Behaviors of Ni-Based Single Crystal Superalloys, Mater. Des., 2017, 130, p 69–82.

M. Mrotzek and E. Nembach, Ostwald ripening of precipitates during two successive heat treatments performed at different temperatures, Acta Mater., 2008, 56, p 150–154.

K. Kim and P.W. Voorhees, Ostwald Ripening of Spheroidal Particles in Multicomponent Alloys, Acta Mater., 2018, 152, p 327–337.

T.D. Xu, S.H. Song, H.Z. Shi, Z.X. Yuan and W. Gust, The diffusion Coefficient of Vacancy-Boron Complexes During the Segregation of Boron Atoms to Grain Boundaries, Mater. Sci. Forum., 1992, 94–96, p 519–524.

W. Chen, M.C. Chaturvedi, N.L. Richards and G. Mcmahon, Grain Boundary Segregation of Boron in Inconel 718, Metall. Mater. Trans. A, 1998, 29(7), p 1947–1954.

S.A. Hosseini, S.M. Abbasi and K.Z. Madar, The Effect of Boron and Zirconium on Microstructure and Tensile Properties of the Wrought Nickel-Based Superalloy ATI 718Plus, Mater. Sci. Eng. A, 2018, 712(JAN.17), p 780–789.

H.W. Wang, J.X. Yang, J. Meng, S.W. Ci, Y.H. Yang, N.C. Sheng, Y.Z. Zhou and X.F. Shun, Effects of B Content on Microstructure and High-Temperature Stress Rupture Properties of a High Chromium Polycrystalline Nickel-Based Superalloy, J. Alloys Compd., 2021, 860(157929), p 1–11.

B.C. Yan, J. Zhang and L.H. Lou, Effect of Boron Additions on the Microstructure and Transverse Properties of A Directionally Solidified Superalloy, Mater. Sci. Eng. A, 2008, 474, p 39–47.

G.D. Zhao, F. Liu, X.M. Zang and W.R. Sun, Microstructure and Hot Ductility Behavior of Ni-Based Superalloy U720Li with Boron Addition, Rare Met., 2021, 40, p 1145–1154.

P. Kontis, H.A. Mohd Yusof, S. Pedrazzini, M. Danaie, K.L. Moore, P.A.J. Bagot, M.P. Moody, C.R.M. Grovenor and R.C. Reed, On the Effect of Boron on Grain Boundary Character in a New Polycrystalline Superalloy, Acta Mater., 2016, 103, p 688–699.

G.D. Zhao, X.M. Zang, Y. Jing, N. Nü and J.J. Wu, Role of Carbides on Hot Deformation Behavior and Dynamic Recrystallization of Hard-Deformed Superalloy U720Li, Mater. Sci. Eng. A, 2021, 815(141293), p 1–9.

N. D’souza, W. Li, C. Argyrakis, G.D. West and C.D. Slater, On the Evolution of Primary Gamma Prime Precipitates During High Temperature and High Strain Rate Deformation and Subsequent Heat Treatment in the Ni-Based Superalloy, RR1000, Metall. Mater. Trans. A, 2019, 50(11), p 4205–4222.

S. Mandal, M. Jayalakshmi, A.K. Bhaduri and V.S. Srama, Effect of Strain Rate on the Dynamic Recrystallization Behavior in a Nitrogen-Enhanced 316L(N), Metall. Mater. Trans. A, 2014, 45(9), p 5645–5656.

Acknowledgment

The authors appreciate the financial supports by National Science and Technology Major Project [2017-VI-0009-0080].

Funding

This study was supported by National Science and Technology Major Project [2017-VI-0009-0080].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Cheng, J., Ma, X. et al. Effect of Boron and Carbon on the Hot Deformation Behavior of a Novel Third Generation Nickel-Based Powder Metallurgy Superalloy WZ-A3. J. of Materi Eng and Perform 31, 5340–5357 (2022). https://doi.org/10.1007/s11665-022-06674-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06674-y