Abstract

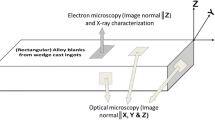

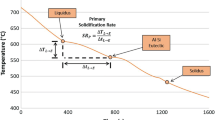

In this study, the influences of solidification rate and grain refinement on the microstructure, hardness and electrical conductivity of a novel Al-Cu alloy for automotive cylinder heads were investigated. The influence of solution heat treatment temperature on the microstructure and hardness was also investigated. Thermal analysis, optical microscopy, SEM-EDX, Rockwell hardness and eddy current tests were conducted to provide a comprehensive characterization of the Al-Cu alloy. The results showed microstructural refinement with increasing solidification rate and with TiBor addition. Increased cooling rate through mold temperature control and the addition of TiBor had a synergistic effect on the solidification rate, resulting in a 28% increase in hardness. The predominant phase in this alloy was found to be Al2Cu. As well, Al-Zr and Al-Fe-Cu-Mn phases were also observed exhibiting a blocky morphology. The conductivity measured from the castings was approximately 28% IACS. The electrical conductivity of the alloy was not influenced by solidification rate; however, TiBor additions reduced the conductivity slightly. Preliminary solution heat treatment experiments demonstrated that the maximum temperature can be increased to 540 °C, without incipient melting. The correlations developed in this study elucidate opportunities for further enhancement of materials for automotive applications.

Similar content being viewed by others

References

J. Davis, ASM Specialty Handbook: Aluminum and Aluminum Alloys, ASM International, Materials Park, 1993.

D. Larouche and M. Javidani, Application of Cast Al-Si Alloys in Internal Combustion Engines, Int. Mater. Rev., 2010, 59(3), p 132–158.

G. Sigworth and J. Major, Factors Influencing the Mechanical Properties of B206, TMS Light Met., 2006, 4, p 795–799.

G. Sigworth and F. DeHart, Recent Developments in the High Strength Aluminum-Copper Casting Alloy A206, AFS Trans., 2003, 111, p 341–345.

H. Kamga, D. Larouche, M. Bournane and A. Rahem, Mechanical Properties of Aluminum-Copper B206 Alloys With Iron and Silicon Additions, Int. J. Cast Met. Res., 2012, 25, p 15–25.

F. D’Elia, C. Ravindran and D. Sediako, Interplay Among Solidification, Microstructure, Residual Strain and Hot Tearing in B206 Aluminum Alloy, Mater. Sci. Eng. A, 2015, 624, p 169–180.

F. D’Elia, C. Ravindran, D. Sediako, K.U. Kainer and N. Hort, Hot Tearing Mechanisms of B206 Aluminum–Copper Alloy, Mater. Des., 2014, 64, p 169–180.

F. D’Elia, C. Ravindran and D. Sediako, Effect of Grain Refinement on Residual Strain and Hot Tearing in B206 Aluminum Alloy, Adv. Mater. Res., 2012, 409, p 35–40.

K. Liu, X. Cao and X. Chen, Effect of Mn, Si, and Cooling Rate on the Formation of Iron-Rich Intermetallics in 206 Al-Cu Cast Alloys, Metall. Mater. Trans. B, 2012, 43B, p 1231–1240.

S. Fentazi, M. Bournane, K.A. Ragab and B. Mehdi, Influence of Mg Additions on Solidification and Performance of B206-Type Aluminum Castings of High Fe and Si Contents, Int. J. Cast Met. Res., 2018, 31(1), p 14–19.

L. Backerud, L. Chai and J. Tamminen, Solidification Characteristics of Aluminum Alloys Volume 2: Foundry Alloys, AFS/ SKANALUMINUM, Stockholm, Sweden, 1990.

A. Girgis, M.H. Abdelaziz, A.M. Samuel, S. Valtierra and F.H. Samuel, On the Enhancement of the Microstructure and Tensile Properties of an Al-Cu Based Cast Alloy, Metall. Microstruct. Anal., 2019, 8(5), p 757–769.

A. Girgis, A.M. Samuel, H.W. Doty, S. Valtierra and F.H. Samuel, On the Elevated Temperature, Tensile Properties of Al-Cu Cast Alloys: Role of Heat Treatment, Adv. Mater. Sci. Eng., 2019, 2019, p 1–15.

S. Dietz, M.B. Djurdjevic, R.F. Gutiérrez and M. Rafetzeder, Solidification Path of NemAlloy, in Vehicle and Automotive Engineering, 2018.

K. Kashyap, Effect of Zirconium Addition on the Recrystallization Behaviour of Commercial Al-Cu-Mg Alloy, Bull. Mater. Sci., 2001, 24(6), p 643–648.

E. Vandersluis and C. Ravindran, Comparison of Measurement Methods for Secondary Dendrite Arm Spacing, Metall. Microstruct. Anal., 2017, 6(1), p 89–94.

H.K. Kamga, D. Larouche, M. Bournane and A. Rahem, Solidification of Aluminum-Copper B206 alloys with Iron and Silicon Additions, Metall. Mater. Trans. A, 2010, 41(11), p 2844–2855.

F. D'Elia, A Study on Grain Refinement and Hot Tearing in Permanent Mold Cast Aluminum Alloys, MASc thesis, Ryerson University, 2009.

B. Andilab, C. Ravindran, N. Dogan, A. Lombardi and G. Byczynski, In-situ Analysis of Incipient Melting of Al2Cu in a Novel High Strength Al-Cu Casting Alloy Using Laser Scanning Confocal Microscopy, Mater. Charact., 2020, 159, p 110064.

J. Zhang, D. Ding, W. Zhang and S. Kang, Effect of Zr Addition on Microstructure and Properties of Al-Mn-Si-Zn-Based Alloy, Trans. Nonferrous Met. Soc. China, 2014, 24, p 3872–3878.

N. Ridley, E. Cullen and E. Humphreys, Effect of Thermomechanical Processing on Evolution of Superplastic Microstructures in Al-Cu-Zr alloys, Mater. Sci. Technol., 2000, 16, p 117–124.

A. Samuel, H. Doty, S. Valtierra and F. Samuel, Defects Related to Incipient Melting, Mater. Des., 2013, 52, p 947–956.

O. Reiso, H. Overlie and N. Ryum, Dissolution and Melting of Secondary Al2Cu Phase Particles in an AlCu Alloy, Metall. Trans. A, 1990, 21A, p 1689–1695.

F. Samuel, Incipient Melting of Al5Mg8Si6Cu2 and Al2Cu Intermetallics in Unmodified and Strontium-Modified Al-Si-Cu-Mg (319) Alloys During Solution Heat Treatment, J. Mater. Sci., 1998, 33, p 2283–2297.

A. Mohamed, F. Samuel and S. Al Kahtani, Influence of Mg and Solution Heat Treatment on the Occurrence Of Incipient Melting in Al-Si-Cu-Mg Cast Alloys, Mater. Sci. Eng. A, 2012, 543, p 22–34.

E. Vandersluis and C. Ravindran, The Role of Porosity in Reducing the Thermal Conductivity of B319 Al Alloy with Decreasing Solidification Rate, JOM, 2019, 71(6), p 2072–2077.

E. Vandersluis, P. Emadi, B. Andilab and C. Ravindran, The Role of Silicon Morphology in the Electrical Conductivity and Mechanical Properties of As-Cast B319 Aluminum Alloy, Metall. Mater. Trans. A, 2020, 51(4), p 1874–1886.

Acknowledgments

The authors are thankful to the Natural Sciences and Engineering Research Council of Canada (NSERC) for financial support of this project (RGPIN-2020-06096). The first three authors acknowledge NSERC-Canada Graduate Scholarships. The authors are thankful to Nemak Linz and Nemak Canada for supporting this project and for in-kind contributions. The authors thank Dr. Anthony Lombardi and Dr. Robert MacKay of Nemak Canada for technical discussions. The authors thank Dr. Raiden Acosta of the University of Toronto for the use of Differential Scanning Calorimeter. The authors also thank Mr. Alan Machin, Mr. Qiang Li, Dr. Raja Roy, and Michael Rinaldi for assistance with experiments and discussions. They are also grateful to the members of the Center for Near-net-shape Processing of Materials for assistance with casting experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Andilab, B., Vandersluis, E., Emadi, P. et al. Characterization of a Cast Al-Cu Alloy for Automotive Cylinder Head Applications. J. of Materi Eng and Perform 31, 5679–5688 (2022). https://doi.org/10.1007/s11665-022-06632-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06632-8