Abstract

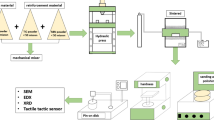

The present study deals with exploring the effect of adding hexagonal boron nitride (0, 0.5, 1 and 1.5) in weight percentage as reinforcement in matrix material aluminum alloy A380, on the mechanical and tribological properties using ultrasonic cavitation process. Scanning electron microscopy (SEM), optical microscope (OM) and energy-dispersive x-ray spectroscopy (EDS) are used to characterize the fabricated composites. Furthermore, tensile, hardness and wear tests by varying applied loads and sliding speeds using pin on disk tribometer are performed on the fabricated composites. It is concluded that the ultrasonic cavitation process distributes the nano-powder uniformly and efficiently. The increase in ultimate tensile strength (130-180 MPa), Brinell hardness (69.5-86 BHN) and enhanced tribological properties are observed for fabricated composite as compared to the base alloy A380.

Similar content being viewed by others

References

S.V. Prasad and R. Asthana, Aluminum Metal-Matrix Composites for Automotive Applications: Tribological Considerations, Tribol. Lett., 2004, 17(3), p 445–453.

S. Liu, Y. Wang, T. Muthuramalingam and G. Anbuchezhiyan, Effect of B4C and MOS2 Reinforcement on Microstructure and Wear Properties of Aluminium Hybrid Composite for Automotive Applications, Compos. Part B Eng., 2019, 176, p 107329.

X. Qiu, L. Qi, J.R. Tang, X.Y. Cui, H. Du, J.Q. Wang and T.Y. Xiong, Influence of Particulate Morphology on Microstructure and Tribological Properties of Cold Sprayed A380/Al2O3 Composite Coatings, J. Mater. Sci. Technol., 2020, 44, p 9–18.

S. García-Rodríguez, N. Alba-Baena, N.M. Rudolph, J. Wellekoetter, X.C. Li and T.A. Osswald, Dimensional Analysis and Scaling in Mechanical Mixing for Fabrication of Metal Matrix Nanocomposites, J. Manuf. Process., 2012, 14(3), p 388–392.

J. Singh, N. Alba-Baena, R. Trehan and V.S. Sharma, An experimental Study on Mechanical Properties and Wear of A380/nB4C Composites Fabricated Using Two Different Liquid State Processes, Sādhanā, 2021, 46(4), p 1–14.

S. Gencalp and N. Saklakoglu, Semisolid Microstructure Evolution During Cooling Slope Casting Under Vibration of A380 Aluminum Alloy, Mater. Manuf. Process., 2010, 25(9), p 943–947.

R. Zheng, X. Hao, Y. Yuan, Z. Wang, K. Ameyama and C. Ma, Effect of High-Volume Fraction of B4C Particles on the Microstructure and Mechanical Properties of Aluminum Alloy-Based Composites, J. Alloy. Compd., 2013, 576, p 291–298.

K.B. Lee, H.S. Sim, S.W. Heo, H.R. Yoo, S.Y. Cho and H. Kwon, Tensile Properties and Microstructures of Al Composite Reinforced with BN Particles, Compos. A Appl. Sci. Manuf., 2002, 33(5), p 709–715.

F. Aydın, Investigation of Elevated Temperature Wear Behavior of Al 2024-BN Composites using Statistical Techniques, J. Mater. Eng. Perform., 2021, 2021, p 1–19.

W. Zhuang, H. Yang, W. Yang, J. Cui, L. Huang, C. Wu, J. Liu, Y. Sun and C. Meng, Microstructure, Tensile Properties, and Wear Resistance of In Situ TiB2/6061 Composites Prepared by High Energy Ball Milling and Stir Casting. J. Mater. Eng. Perform., 2021, p 1-11

R. Sandeep, A.K. Jeevanantham, M. Manikandan, N. Arivazhagan and S. Tofil, Multi-Performance Optimization in Friction Stir Welding of AA6082/B4C Using Genetic Algorithm and Desirability Function Approach for Aircraft Wing Structures. J. Mater. Eng. Perform. 2021, p 1-13

M. Khakbiz and F. Akhlaghi, Synthesis and Structural Characterization of Al–B4C Nanocomposite Powders by Mechanical Alloying, J. Alloy. Compd., 2009, 479(1/2), p 334–341.

C.Z. Nie, J.J. Gu, J.L. Liu and D. Zhang, Production of Boron Carbide Reinforced 2024 Aluminium Matrix Composites by Mechanical Alloying, Mater. Trans., 2007, 48(5), p 990–995.

H. Pouraliakbar, A. Nazari, P. Fataei, A.K. Livary and M. Jandaghi, Predicting Charpy Impact Energy of Al6061/SiCp Laminated Nanocomposites in Crack Divider and Crack Arrester Forms, Ceram. Int., 2013, 39(6), p 6099–6106.

A. Alizadeh and E. Taheri-Nassaj, Mechanical Properties and Wear Behavior of Al–2 wt.% Cu Alloy Composites Reinforced by B4C Nanoparticles and Fabricated by Mechanical Milling and Hot Extrusion, Mater. Charact., 2012, 67, p 119–128.

A.H. Monazzah, H. Pouraliakbar, R. Bagheri and S.M.S. Reihani, Al-Mg-Si/SiC Laminated Composites: Fabrication, Architectural Characteristics, Toughness, Damage Tolerance, Fracture Mechanisms, Compos. B Eng., 2017, 125, p 49–70.

H. Pouraliakbar, A.H. Monazzah, R. Bagheri, S.S. Reihani, G. Khalaj, A. Nazari and M.R. Jandaghi, Toughness Prediction in Functionally Graded Al6061/SiCp Composites Produced by Roll-Bonding, Ceram. Int., 2014, 40(6), p 8809–8825.

X. Liu, S. Jia and L. Nastac, Ultrasonic Cavitation-Assisted Molten Metal Processing of Cast A356-Nanocomposites, Int. J. Metalcast., 2014, 8(3), p 51–58.

R. Harichandran and N. Selvakumar, Effect of Nano/Micro B4C Particles on the Mechanical Properties of Aluminium Metal Matrix Composites Fabricated by Ultrasonic Cavitation-Assisted Solidification Process, Archiv. Civ. Mech. Eng., 2016, 16, p 147–158.

C. Sun, M. Song, Z. Wang and Y. He, Effect of Particle Size on the Microstructures and Mechanical Properties of SiC-Reinforced Pure Aluminum Composites, J. Mater. Eng. Perform., 2011, 20(9), p 1606–1612.

N. Alba-Baena, T. Pabel, N. Villa-Sierra and D.G. Eskin, Effect of Ultrasonic Melt Treatment on Degassing and Structure of Aluminium Alloys, Mater. Sci. Forum, 2013, 765, p 271–275.

S. Singh, A. Gupta, V.S. Sharma and R. Harichadaran, Production and High Temperature Wear Characterization of AA 7075/Al2O3/Graphite Hybrid Nanocomposites by Enhanced Stir and Ultrasound Assisted Casting Method, Mater. Res. Exp., 2019, 6(12), p 125072.

A. Miranda, N. Alba-Baena, B.J. McKay, D.G. Eskin, S.H. Ko and J.S. Shin, Study of Mechanical Properties of an LM24 Composite Alloy Reinforced with Cu-CNT Nanofillers, Processed Using Ultrasonic Cavitation, Mater. Sci. Forum, 2013, 765, p 245–249.

S. Gudipudi, S. Nagamuthu, K.S. Subbian and S.P.R. Chilakalapalli, Enhanced Mechanical Properties of AA6061-B4C Composites Developed by a Novel Ultra-Sonic Assisted Stir Casting, Eng. Sci. Technol. Int. J., 2020, 23, p 1233–1243.

A.E.P.A. Baradeswaran and A.E. Perumal, Influence of B4C on the Tribological and Mechanical Properties of Al 7075–B4C Composites, Compos. B Eng., 2013, 54, p 146–152.

J. Li, S. Lü, S. Wu, W. Guo and F. Li, Variation of Microstructure and Mechanical Properties with Nano-SiCp Levels in the Nano-SiCp/AlCuMnTi Composites, J. Alloy. Compd., 2018, 769, p 848–857.

J. Prakash, S. Gopalakannan and V.K. Chakravarthy, Mechanical Characterization Studies of Aluminium Alloy 7075 Based Nanocomposites. Silicon, 2021, p 1-12

U. Aybarç, O. Ertuğrul and M.Ö. Seydibeyoğlu, Effect of Al2O3 Particle Size on Mechanical Properties of Ultrasonic-Assisted Stir-Casted Al A356 Matrix Composites, Int. J. Metalcast., 2021, 15(2), p 638–649.

G.I. Eskin and D.G. Eskin, Ultrasonic treatment of light alloy melts, CRC Press, Boca Raton, 2014.

J. Lei, J. Yu, J. Chen, C. Li, H. Luo and Z. Li, Effect of Trace Sr and Sc Contents and Ultrasonic Vibration on the Microstructure and Mechanical Properties of the A380 Alloy, Adv. Mech. Eng., 2018, 10(5), p 1–9.

Y. Zhang, J. Jie, Y. Gao, Y. Lu and T. Li, Effects of Ultrasonic Treatment on the Formation of Iron-Containing Intermetallic Compounds in Al-12% Si-2% Fe Alloys, Intermetallics, 2013, 42, p 120–125.

B.N. Du, Z.Y. Hu, L.Y. Sheng, D.K. Xu, Y.X. Qiao, B.J. Wang, J. Wang, Y.F. Zheng and T.F. Xi, Microstructural Characteristics and Mechanical Properties of the Hot Extruded Mg-Zn-Y-Nd Alloys, J. Mater. Sci. Technol., 2021, 60, p 44–55.

K.L. Firestein, A.E. Steinman, I.S. Golovin, J. Cifre, E.A. Obraztsova, A.T. Matveev, A.M. Kovalskii, O.I. Lebedev, D.V. Shtansky and D. Golberg, Fabrication, Characterization, and Mechanical Properties of Spark Plasma Sintered Al–BN Nanoparticle Composites, Mater. Sci. Eng., A, 2015, 2015(642), p 104–112.

S. Chen, Y. Bi, H. Zhang, J. Liang, D. Wellburn and L.I.U. Chang-sheng, Effect of BN Fraction on the Mechanical and Tribological Properties of Cu Alloy/BN Self-Lubricating Sleeves, J. Compos. Mater., 2015, 49(30), p 3715–3725.

R. Harichandran and N. Selvakumar, Microstructure and Mechanical Characterization of (B4C+h-BN)/Al Hybrid Nanocomposites Processed by Ultrasound Assisted Casting, Int. J. Mech. Sci., 2018, 144, p 814–826.

N. Soltani, M.I. Pech-Canul and A. Bahrami, Effect of 10Ce-TZP/Al2O3 Nanocomposite Particle Amount and Sintering Temperature on the Microstructure and Mechanical Properties of Al/(10Ce-TZP/Al2O3) Nanocomposites, Mater. Des., 2013, 50, p 85–91.

P. Madhukar, N. Selvaraj, C.S.P. Rao and G.V. Kumar, Fabrication and Characterization Two Step Stir Casting with Ultrasonic Assisted Novel AA7150-hBN Nanocomposites, J. Alloys Comp., 2020, 815, p 152464.

R.S. Rana, R. Purohit and S. Rana, Synthesis & Analysis of Mechanical Properties of LM24/B4C Particulate Composites, Mater. Today Proc., 2018, 5(2), p 6038–6044.

X. Liu, Y. Liu, D. Huang, Q. Han and X. Wang, Tailoring In-Situ TiB2 Particulates in Aluminum Matrix Composites, Mater. Sci. Eng. A, 2017, 705, p 55–61.

R. Ahmad, N.A. Wahab, S. Hasan, Z. Harun, M.M. Rahman and N.R. Shahizan, Effect of Erbium Addition on the Microstructure and Mechanical Properties of Aluminium Alloy, Key Eng. Mater., 2019, 796, p 62–66.

J. Lei, J. Yu, J. Chen, C. Li, H. Luo and Z. Li, Effect of Trace Sr and Sc Contents and Ultrasonic Vibration on the Microstructure and Mechanical Properties of the A380 Alloy, Adv. Mech. Eng., 2018, 10(5), p 1687814018775172.

S. Sivakumar, K.P. Padmanaban and M. Uthayakumar, Wear Behavior of the Al (LM24)–Garnet Particulate Composites Under Dry Sliding Conditions, Proc. Inst. Mech. Eng. Part J J. Eng. Tribol., 2014, 228(12), p 1410–1420.

N. Barekar, S. Tzamtzis, B.K. Dhindaw, J. Patel, N.H. Babu and Z. Fan, Processing of Aluminum-Graphite Particulate Metal Matrix Composites by Advanced Shear Technology, J. Mater. Eng. Perform., 2009, 18(9), p 1230–1240.

M.R. Rosenberger, C.E. Schvezov and E. Forlerer, Wear of Different Aluminum Matrix Composites Under Conditions that Generate a Mechanically Mixed Layer, Wear, 2005, 259(1–6), p 590–601.

V.C. Uvaraja, N. Natarajan, K. Sivakumar, S. Jegadheeshwaran and S. Sudhakar, Tribological Behavior of Heat Treated Al 7075 Aluminium Metal Matrix Composites, Indian J. Eng. Mater. Sci., 2015, 22, p 51–61.

M. Demirel and M. Muratoglu, Influence of Load and Temperature on the Dry Sliding Wear Behavior of Aluminium-Ni 3 Al Composites, Indian J. Eng. Mater. Sci., 2011, 2011(18), p 268–282.

G.J. Howell and A. Ball, Dry Sliding Wear of Particulate-Reinforced Aluminium Alloys Against Automobile Friction Materials, Wear, 1995, 181, p 379–390.

A. Mazahery and M.O. Shabani, Investigating the Effect of Reinforcing Particulates on the Weight Loss and Worn Surface of Compocast AMCs, Kovove Mater., 2013, 51, p 11–18.

L.Y. Sheng, F. Yang, T.F. Xi and J.T. Guo, Investigation on Microstructure and Wear Behavior of the NiAl–TiC–Al2O3 Composite Fabricated by Self-Propagation High-Temperature Synthesis with Extrusion, J. Alloy. Compd., 2013, 554, p 182–188.

U. Soy, A. Demir and F. Findik, Friction and Wear Behaviors of Al-SiC-B4C Composites Produced by Pressure Infiltration Method, Ind. Lubr. Tribol., 2011, 63(5), p 387–393.

Acknowledgments

The authors would like to thank the Department of Mechanical Engineering, Sant Longowal Institute of Engineering & Technology (SLIET) Longowal, Punjab, India, for providing the testing facilities. The authors would also like to thank Mr Ravi Kumar for providing the machining facilities at Siddh Auto Components Faridabad, Haryana, India.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, J., Alba-Baena, N., Trehan, R. et al. Microstructure, Mechanical Properties and Tribological Behavior of A380/Nano-Hexagonal Boron Nitride Metal Matrix Composite. J. of Materi Eng and Perform 31, 4887–4901 (2022). https://doi.org/10.1007/s11665-021-06570-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06570-x