Abstract

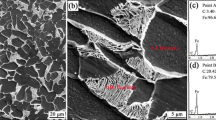

The trace dissolved oxygen has a dual role in corrosion of 3Cr steel in CO2 aqueous environment, and the content determines which role is dominant. The corrosion rate in CO2-2.15 ppm O2 environment is lower than that in pure CO2 environment. However, it dramatically reaches 3.184 mm/y when the O2 content is 6.32 ppm. The corrosion scale possesses a single Cr-rich layer in CO2 environment, while that in CO2-2.15 ppm O2 environment consists of a Cr-rich inner layer, a Cr-Fe mixed middle layer, and a porous outer layer. When the O2 content is low, O2 promotes the dissolution of Cr and the formation of Cr(OH)3, resulting in the increase of Cr-rich layer thickness and the decrease of corrosion rate. Besides, there is not enough O2 to completely oxidize Fe2+ to Fe3+, thus protecting the integrity of the inner film composed of Cr(OH)3 and FeCO3. When the O2 content increases to 6.32 ppm, Fe3+ compounds, and Cr(OH)3 compete for deposition on the surface. O2 promotes the formation of Fe3+ compounds, causing Fe3+ compounds to occupy the position of Cr(OH)3 in the inner film and Cr compounds are isolated. Then the uneven distribution of Cr element in the inner film results in significant pitting corrosion.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

X. Gao, D. Zhang, Y. Lu, Z. Fan, L. Du, G. Yuan, C. Qiu, and J. Kang, CO2 Corrosion Behavior of High-Strength and Toughness V140 Steel for Oil Country Tubular Goods, J. Mater. Eng. Perform., 2020, 29, p 8451–8460.

Z.F. Yin, Y.L. Zhang, G.R. Chang, and T.Q. Yang, Corrosion Behavior and Characteristics of 3Cr Steel in Coexisting H2S- and CO2-Containing Solutions, J. Mater. Eng. Perform., 2020, 29, p 5442–5457.

Q. Li, H. Hu, and Y.F. Cheng, Corrosion of Pipelines in CO2-Saturated Oil-Water Emulsion Flow Studied by Electrochemical Measurements and Computational Fluid Dynamics Modeling, J. Pet. Sci. Eng., 2016, 147, p 408–415.

A. Kahyarian, M. Singer, and S. Nesic, Modeling of Uniform CO2 Corrosion of Mild Steel in Gas Transportation Systems: A review, J. Nat. Gas Sci. Eng., 2016, 29, p 530–549.

W. Liu, S. Lu, Y. Zhang, Z. Fang, X. Wang, and M. Lu, Corrosion Performance of 3%Cr Steel in CO2-H2S Environment Compared with Carbon Steel, Mater. Corros., 2015, 66, p 1232–1244.

S. Guo, L. Xu, L. Zhang, W. Chang, and M. Lu, Characterization of Corrosion Scale Formed on 3Cr Steel in CO2-Saturated Formation Water, Corros. Sci., 2016, 110, p 123–133.

Y. Zhang, G. Zhao, and Y.F. Cheng, Downhole O2 Corrosion during Air-Assisted Steam Injection for Secondary or Tertiary Oil Recovery, Corros. Eng. Sci. Technol., 2020, 55, p 189–195.

X. Zhong, W. Lu, H. Yang, M. Liu, Y. Zhang, H. Liu, J. Hu, Z. Zhang, and D. Zeng, Oxygen Corrosion of N80 Steel under Laboratory Conditions Simulating High Pressure Air Injection: Analysis of Corrosion Products, J. Pet. Sci. Eng., 2019, 172, p 162–170.

J. Sun, C. Sun, and Y. Wang, Effects of O2 and SO2 on Water Chemistry Characteristics and Corrosion Behavior of X70 Pipeline Steel in Supercritical CO2 Transport System, Int. Eng. Chem. Res., 2018, 57, p 2365–2375.

V. Jovancicevic and J.O. Bockris, The Mechanism of Oxygen Reduction on Iron in Neutral Solutions, J. Electrochem. Soc., 1986, 133, p 1797–1807.

L. Cáceres, T. Vargas, and L. Herrera, Determination of Electrochemical Parameters and Corrosion Rate for Carbon Steel in Un-Buffered Sodium Chloride Solutions Using a Superposition Model, Corros. Sci., 2007, 49, p 3168–3184.

G.K.H. Wiberg and M. Arenz, On the Influence of Hydronium and Hydroxide Ion Diffusion on the Hydrogen and Oxygen Evolution Reactions in Aqueous Media, Electrochim. Acta, 2015, 158, p 13–17.

Y.S. Choi, S. Nesic, and D. Young, Effect of Impurities on the Corrosion Behavior of CO2 Transmission Pipeline Steel in Supercritical CO2-Water Environments, Environ. Sci. Technol., 2010, 44, p 9233–9238.

L. Teeter, R. Repukaiti, N. Huerta, R.P. Oleksak, R.B. Thomas, Ö.N. Doğan, M. Ziomek-Moroz, and J.D. Tucker, Effect of O2 on the Long-Term Operation and Corrosion of Steel X65 in CO2-H2O Environments for Direct Supercritical CO2 Power Cycle Applications, J. Supercrit. Fluids, 2019, 152, p 104520.

L. Chen, J. Hu, X. Zhong, Q. Zhang, Y. Zheng, Z. Zhang, and D. Zeng, Corrosion Behaviors of Q345R Steel at the Initial Stage in an Oxygen-Containing Aqueous Environment: Experiment and Modeling, Materials, 2018, 11, p 1462.

F.M. Song, D.W. Kirk, J.W. Graydon, and D.E. Cormack, Predicting Carbon Dioxide Corrosion of Bare Steel under an Aqueous Boundary Layer with Oxygen and Cathodic Protection, Corrosion, 2004, 60, p 845–851.

J. Sun, C. Sun, G. Zhang, X. Li, W. Zhao, T. Jiang, H. Liu, X. Cheng, and Y. Wang, Effect of O2 and H2S Impurities on the Corrosion Behavior of X65 Steel in Water-Saturated Supercritical CO2 System, Corros. Sci., 2016, 107, p 31–40.

X. Lin, W. Liu, F. Wu, C. Xu, J. Dou, and M. Lu, Effect of O2 on Corrosion of 3Cr Steel in High Temperature and High Pressure CO2-O2 Environment, Appl. Surf. Sci., 2015, 329, p 104–115.

Y. Hua, R. Barker, and A. Neville, The Effect of O2 Content on the Corrosion Behaviour of X65 and 5Cr in Water-Containing Supercritical CO2 Environments, Appl. Surf. Sci., 2015, 356, p 499–511.

Y. Tang, X.P. Guo, and G.A. Zhang, Corrosion Behaviour of X65 Carbon Steel in Supercritical-CO2 Containing H2O and O2 in Carbon Capture and Storage (CCS) Technology, Corros. Sci., 2016, 107, p 118–128.

D. Huenert and A. Kranzmann, Impact of Oxyfuel Atmospheres H2O/CO2/O2 and H2O/CO2 on the Oxidation of Ferritic–Martensitic and Austenitic Steels, Corros. Sci., 2011, 53, p 2306–2317.

L. Wei and K. Gao, Understanding the General and Localized Corrosion Mechanisms of Cr-Containing Steels in Supercritical CO2-Saturated Aqueous Environments, J. Alloys Compd., 2019, 792, p 328–340.

P. Mills and J.L. Sullivan, A Study of the Core Level Electrons in Iron and Its Three Oxides by Means of x-Ray Photoelectron Spectroscopy, J. Phys. D Appl. Phys., 1983, 16, p 723–732.

J.K. Heuer and J.F. Stubbins, An XPS Characterization of FeCO3 Films from CO2 Corrosion, Corros. Sci., 1999, 41, p 1231–1243.

T.J. Mesquita, E. Chauveau, M. Mantel, and R.P. Nogueira, A XPS Study of the Mo Effect on Passivation Behaviors for Highly Controlled Stainless Steels in Neutral and Alkaline Conditions, Appl. Surf. Sci., 2013, 270, p 90–97.

H. Luo, C.F. Dong, K. Xiao, and X.G. Li, Characterization of Passivefilm on 2205 Duplex Stainless Steel in Sodium Thiosulphate Solution, Appl. Surf. Sci., 2011, 258, p 631–639.

Q. Guo, J. Liu, M. Yu, and S. Li, Effect of Passivefilm on Mechanical Properties of Martensitic Stainless Steel 15-5PH in a Neutral NaCl Solution, Appl. Surf. Sci., 2015, 327, p 313–320.

H. Luo, C.F. Dong, X.G. Li, and K. Xiao, The Electrochemical Behaviour of 2205 Duplex Stainless Steel in Alkaline Solutions with Different pH in the Presence of Chloride, Electrochim. Acta, 2012, 64, p 211–220.

J.O.M. Bockris and D. Drazic, The Kinetics of Deposition and Dissolution of Iron: Effect of Alloying Impurities, Electrochim. Acta, 1962, 7, p 293–313.

S. Nesic, Key Issues Related to Modelling of Internal Corrosion of Oil and Gas Pipelines—A Review, Corros. Sci., 2007, 49, p 4308–4338.

Y. Zhao, T. Zhang, H. Xiong, and F. Wang, Bridge for the Thermodynamics and Kinetics of Electrochemical Corrosion: Modeling on Dissolution, Ionization, Diffusion and Deposition in Metal/Solution Interface, Corros. Sci., 2021, 191, p 109763.

C. Chen, M. Lu, D. Sun, Z. Zhang, and W. Chang, Effect of Chromium on the Pitting Resistance of Oil Tube Steel in a Carbon Dioxide Corrosion System, Corrosion, 2005, 61, p 594–601.

W. Sun, S. Nesic, and R.C. Woollam, The Effect of Temperature and Ionic Strength on Iron Carbonate (FeCO3) Solubility Limit, Corros. Sci., 2009, 51, p 1273–1276.

Acknowledgment

The authors are grateful to the National Natural Science Foundation of China (51571027) and the funding support from the National Key R&D Program of China (2016YFE0203600).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this manuscript, and the manuscript is approved by all authors for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, L., Liu, W., Dong, B. et al. Role of Trace Dissolved Oxygen Content in Corrosion Scale of 3Cr Steel in CO2 Aqueous Environment. J. of Materi Eng and Perform 31, 4864–4876 (2022). https://doi.org/10.1007/s11665-021-06556-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06556-9