Abstract

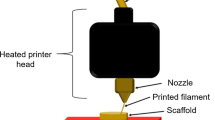

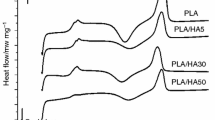

Polymer composite filaments, which consist of polylactic acid (PLA), titanium dioxide (TiO2), synthetic hydroxyapatite (HA) and natural hydroxyapatite (NHA), have been produced via an extruder for using in biomedical applications. Then, 3D printings were produced in a fused deposition modeling (FDM) printer by using these composite filaments. A number of experiments and measurements were made on 3D printed PLA/HA/NHA/TiO2 composite samples. According to the stress–strain analysis of 3D printing samples of PLA/HA/NHA/TiO2 composites, the highest ultimate tensile strength, elastic modulus and elongation at break were 62, 1887 MPa, and 1.76 mm, respectively. According to SEM analysis, HA in PLA contributed to the spread of raster lines, and TiO2 contributed to the smoothness of the raster lines. According to the dimensional accuracy analysis of the composites, the least deviation value was obtained in the samples 3D printed with 95%PLA/2.5%HA/2.5%TiO2 filament at 205 °C extruder temperature. The lowest average roughness value of 95%PLA/4%HA/1%TiO2 composite was 3 µm in the Z-axis plane. According to the data obtained, the extruder temperature is 220 °C, the printing speed is 2880 mm/min, the mixing ratio 95% PLA/4% HA/1% TiO2 can be selected for optimal performance characteristics.

Similar content being viewed by others

References

K. Gnanasekaran, T. Heijmans, S. van Bennekom, H. Woldhuis, S. Wijnia, G. de With and H. Friedrich, 3D Printing of CNT- and Graphene-Based Conductive Polymer Nanocomposites by Fused Deposition Modeling, Appl. Mater. Today, 2017, 9, p 21–28.

P.H.M. Cardoso, M.F.L. Oliveira, M.G. Oliveira, R.M. da Silva Moreira and Thiré, 3D Printed Parts of Polylactic Acid Reinforced with Carbon Black and Alumina Nanofillers for Tribological Applications, Macromol. Symp., 2020, 394(1), p 2000155. https://doi.org/10.1002/masy.202000155

P. Parandoush and D. Lin, A Review on Additive Manufacturing of Polymer-Fiber Composites, Composite Structures, 2017, 182, p 36–53.

Y. Jin, Y. He, J. Fu, W. Gan and Z. Lin, Optimization of Tool-Path Generation for Material Extrusion-Based Additive Manufacturing Technology, Addit. Manuf., 2014, 1–4, p 32–47. https://doi.org/10.1016/j.addma.2014.08.004

O.A. Mohamed, S.H. Masood, J.L. Bhowmik and A.E. Somers, Investigation on the Tribological Behavior and Wear Mechanism of Parts Processed by Fused Deposition Additive Manufacturing Process, J. Manuf. Process., 2017, 29, p 149–159.

N. Hossain, M.A. Chowdhury, M.B.A. Shuvho, M.A. Kashem and M. Kchaou, (2021) 3D-Printed Objects for Multipurpose Applications, J. Mater. Eng. Perform., 2021, 30(7), p 4756–4767. https://doi.org/10.1007/S11665-021-05664-W

J. Torres, M. Cole, A. Owji, Z. DeMastry and A.P. Gordon, An Approach for Mechanical Property Optimization of Fused Deposition Modeling with Polylactic Acid via Design of Experiments, Rapid Prototyp. J., 2016, 22(2), p 387–404.

A.K. Sood, R.K. Ohdar and S.S. Mahapatra, Experimental Investigation and Empirical Modelling of FDM Process for Compressive Strength Improvement, J. Adv. Res., 2012, 3(1), p 81–90.

A.K. Sood, R.K. Ohdar and S.S. Mahapatra, Parametric Appraisal of Mechanical Property of Fused Deposition Modelling Processed Parts, Mater. Des., 2010, 31(1), p 287–295.

G. Strnad, R. Cazacu, P. Chetan, A.S. Gaz Florea, and F. Peti, “Effect of Phosphate/Fluoride Electrolytes on Mass and Dimensional Stability of Anodization Bath Manufactured by FDM,” MATEC Web of Conferences, EDP Sciences, 2017.

A.P. Valerga, M. Batista, R. Puyana, A. Sambruno, C. Wendt and M. Marcos, Preliminary Study of PLA Wire Colour Effects on Geometric Characteristics of Parts Manufactured by FDM, Proc. Manuf., 2017, 13, p 924–931.

S. Wang, D.R. D’hooge, L. Daelemans, H. Xia, K. De Clerck and L. Cardon, The Transferability and Design of Commercial Printer Settings in Pla/Pbat Fused Filament Fabrication, Polymers (Basel)., 2020, 12(11), p 1–20.

T.C. Yang and C.H. Yeh, Morphology and Mechanical Properties of 3D Printed Wood Fiber/Polylactic Acid Composite Parts Using Fused Deposition Modeling (FDM): The Effects of Printing Speed, Polymers (Basel)., 2020, 12(6), p 1334.

A. Selvam, S. Mayilswamy, R. Whenish, R. Velu and B. Subramanian, Preparation and Evaluation of the Tensile Characteristics of Carbon Fiber Rod Reinforced 3D Printed Thermoplastic Composites, J. Compos. Sci., 2020, 5(1), p 8.

B. Coppola, N. Cappetti, L. Di Maio, P. Scarfato and L. Incarnato, Materials 3D Printing of PLA/Clay Nanocomposites: Influence of Printing Temperature on Printed Samples Properties, Materials, 2018 https://doi.org/10.3390/ma11101947

C. Abeykoon, P. Sri-Amphorn and A. Fernando, Optimization of Fused Deposition Modeling Parameters for Improved PLA and ABS 3D Printed Structures, Int. J. Light. Mater. Manuf., 2020, 3(3), p 284–297. https://doi.org/10.1016/j.ijlmm.2020.03.003

Y. Tao and L. Pan, Improving Tensile Properties of Polylactic Acid Parts by Adjusting Printing Parameters of Open Source 3D Printers, MEDŽIAGOTYRA, 2020 https://doi.org/10.5755/j01.ms.26.1.20952

T. Vukasovic, J.F. Vivanco, D. Celentano and C. García-Herrera, Characterization of the Mechanical Response of Thermoplastic Parts Fabricated with 3D Printing, Int. J. Adv. Manuf. Technol, 2019, 104(9–12), p 4207–4218.

T. Yao, Z. Deng, K. Zhang and S. Li, A Method to Predict the Ultimate Tensile Strength of 3D Printing Polylactic Acid (PLA) Materials with Different Printing Orientations, Compos. Part B Eng., 2019, 163, p 393–402.

B. Akhoundi and A.H. Behravesh, Effect of Filling Pattern on the Tensile and Flexural Mechanical Properties of FDM 3D Printed Products, Exp. Mech., 2019, 59(6), p 883–897. https://doi.org/10.1007/s11340-018-00467-y

G. Wang, D. Zhang, B. Li, G. Wan, G. Zhao and A. Zhang, Strong and Thermal-Resistance Glass Fiber-Reinforced Polylactic Acid (PLA) Composites Enabled by Heat Treatment, Int. J. Biol. Macromol., 2019, 129, p 448–459. https://doi.org/10.1016/j.ijbiomac.2019.02.020

S. Lin Yang, Z.H. Wu, W. Yang and M.B. Yang, Thermal and Mechanical Properties of Chemical Crosslinked Polylactide (PLA), Polym. Test., 2008, 27(8), p 957–963.

P. Törmälä, S. Vainionpää, J. Kilpikari and P. Rokkanen, The Effects of Fibre Reinforcement and Gold Plating on the Flexural and Tensile Strength of PGA/PLA Copolymer Materials in Vitro, Biomaterials, 1987, 8(1), p 42–45.

S. Ochi, Mechanical Properties of Kenaf Fibers and Kenaf/PLA Composites, Mech. Mater., 2008, 40(4–5), p 446–452. https://doi.org/10.1016/j.mechmat.2007.10.006

B. Bax and J. Müssig, Impact and Tensile Properties of PLA/Cordenka and PLA/Flax Composites, Composites Science and Technology, 2008, 68, p 1601–1607.

R. Auras, B. Harte and S. Selke, An Overview of Polylactides as Packaging Materials, Macromolecular Bioscience, 2004 https://doi.org/10.1002/mabi.200400043

J. Torres, J. Cotelo, J. Karl and A.P. Gordon, Mechanical Property Optimization of FDM PLA in Shear with Multiple Objectives, JOM, 2015, 67(5), p 1183–1193. https://doi.org/10.1007/s11837-015-1367-y

R. Aziz, M.I. Ul Haq and A. Raina, Effect of Surface Texturing on Friction Behaviour of 3D Printed Polylactic Acid (PLA), Polym. Test, 2020 https://doi.org/10.1016/j.polymertesting.2020.106434

M.H. Helal, H.D. Hendawy, R.A. Gaber, N.R. Helal and M.N. Aboushelib, Osteogenesis Ability of CAD-CAM Biodegradable Polylactic Acid Scaffolds for Reconstruction of Jaw Defects, J. Prosthet. Dent., 2019, 121(1), p 118–123.

E.V. Melnik, S.N. Shkarina, S.I. Ivlev, V. Weinhardt, T. Baumbach, M.V. Chaikina, M.A. Surmeneva and R.A. Surmenev, In Vitro Degradation Behaviour of Hybrid Electrospun Scaffolds of Polycaprolactone and Strontium-Containing Hydroxyapatite Microparticles, Polym. Degrad. Stab., 2019, 167, p 21–32.

M. Sadat-Shojai, M.T. Khorasani, E. Dinpanah-Khoshdargi and A. Jamshidi, Synthesis Methods for Nanosized Hydroxyapatite with Diverse Structures, Acta Biomaterialia, 2013, 9, p 7591–7621.

G. Montalbano, G. Molino, S. Fiorilli and C. Vitale-Brovarone, Synthesis and Incorporation of Rod-like Nano-Hydroxyapatite into Type I Collagen Matrix: A Hybrid Formulation for 3D Printing of Bone Scaffolds, J. Eur. Ceram. Soc., 2020, 40(11), p 3689–3697.

T.T. Hoai, N.K. Nga, L.T. Giang, T.Q. Huy, P.N.M. Tuan and B.T.T. Binh, Hydrothermal Synthesis of Hydroxyapatite Nanorods for Rapid Formation of Bone-Like Mineralization, J. Electron. Mater., 2017, 46(8), p 5064–5072.

J. Li, X.L. Lu and Y.F. Zheng, Effect of Surface Modified Hydroxyapatite on the Tensile Property Improvement of HA/PLA Composite, Appl. Surf. Sci., 2008, 255(2), p 494–497.

M. Luna, J. Delgado, M. Gil and M. Mosquera, TiO2-SiO2 Coatings with a Low Content of AuNPs for Producing Self-Cleaning Building Materials, Nanomaterials, 2018, 8(3), p 177. https://doi.org/10.3390/nano8030177

D. Colangiuli, M. Lettieri, M. Masieri and A. Calia, Field Study in an Urban Environment of Simultaneous Self-Cleaning and Hydrophobic Nanosized TiO2-Based Coatings on Stone for the Protection of Building Surface, Sci. Total Environ., 2019, 650, p 2919–2930.

M. Murugan, R. Subasri, T.N. Rao, A.S. Gandhi and B.S. Murty, Synthesis, Characterization and Demonstration of Self-Cleaning TiO 2 Coatings on Glass and Glazed Ceramic Tiles, Prog. Org. Coatings, 2013, 76(12), p 1756–1760.

C. Sciancalepore, T. Manfredini and F. Bondioli, Antibacterial and Self-Cleaning Coatings for Silicate Ceramics: A Review, Adv. Sci. Technol., 2014, 92, p 90–99. https://doi.org/10.4028/www.scientific.net/ast.92.90

P. Evans and D.W. Sheel, Photoactive and Antibacterial TiO2 Thin Films on Stainless Steel, Surf. Coatings Technol., 2007, 201, p 9319–9324.

N. Sykaras, A.M. Iacopino, V.A. Marker, R.G. Triplett, and R.D. Woody, Implant Materials, Designs, and Surface Topographies: Their Effect on Osseointegration. A Literature Review., Int. J. Oral Maxillofac. Implants, n.d., 15(5), p 675–90, http://www.ncbi.nlm.nih.gov/pubmed/11055135. Accessed 9 November 2020.

L.M. Bjursten, L. Rasmusson, S. Oh, G.C. Smith, K.S. Brammer and S. Jin, Titanium Dioxide Nanotubes Enhance Bone Bonding in Vivo, J. Biomed. Mater. Res. - Part A, 2010, 92(3), p 1218–1224.

T.-C. Yang, Effect of Extrusion Temperature on the Physico-Mechanical Properties of Unidirectional Wood Fiber-Reinforced Polylactic Acid Composite (WFRPC) Components Using Fused Deposition Modeling, Polymers, 2018, 10(9), p 976. https://doi.org/10.3390/POLYM10090976

S. Cheng, K. Tak Lau, T. Liu, Y. Zhao, P.M. Lam and Y. Yin, Mechanical and Thermal Properties of Chicken Feather Fiber/PLA Green Composites, Compos. Part B Eng., 2009, 40(7), p 650–654.

R. Singh, P. Bedi, F. Fraternali and I.P.S. Ahuja, Effect of Single Particle Size, Double Particle Size and Triple Particle Size Al2O3 in Nylon-6 Matrix on Mechanical Properties of Feed Stock Filament for FDM, Compos. Part B Eng., 2016, 106, p 20–27. https://doi.org/10.1016/j.compositesb.2016.08.039

N. Naveed, Investigate the Effects of Process Parameters on Material Properties and Microstructural Changes of 3D-Printed Specimens Using Fused Deposition Modelling (FDM), Mater. Technol., 2020, 36, p 317–330.

S.E. Nájera, M. Michel and N.-S. Kim, 3D Printed PLA/PCL/TiO2 Composite for Bone Replacement and Grafting, MRS Adv., 2018, 3(40), p 2373–2378. https://doi.org/10.1557/adv.2018.375

D. Hodzic and A. Pandzic, “Influence of Carbon Fibers on Mechanical Properties of Materials in Fdm Technology,” Annals of DAAAM and Proceedings of the International DAAAM Symposium, Danube Adria Association for Automation and Manufacturing, DAAAM, 2019, p 334–342.

E. García Plaza, P. Núñez López, M. Caminero Torija and J. Chacón Muñoz, Analysis of PLA Geometric Properties Processed by FFF Additive Manufacturing: Effects of Process Parameters and Plate-Extruder Precision Motion, Polymers Basel., 2019, 11(10), p 1581. https://doi.org/10.3390/polym11101581

K. Tiwari and S. Kumar, Analysis of the Factors Affecting the Dimensional Accuracy of 3D Printed Products, Mater. Today: Proc., 2018, 5, p 18674–18680.

V. Taşdemir, Investigation of Dimensional Integrity and Surface Quality of Different Thin-Walled Geometric Parts Produced via Fused Deposition Modeling 3D Printing, J. Mater. Eng. Perform., 2021, 30(5), p 3381–3387. https://doi.org/10.1007/S11665-021-05809-X

Acknowledgment

This study was funded by the Scientific Research Projects Unit of the University of Firat (FUBAP-MF.20.01). The authors would like to thank FUBAP for its support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Olam, M., Tosun, N. Assessment of 3D Printings Produced in Fused Deposition Modeling Printer Using Polylactic Acid/TiO2/Hydroxyapatite Composite Filaments. J. of Materi Eng and Perform 31, 4554–4565 (2022). https://doi.org/10.1007/s11665-021-06539-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06539-w