Abstract

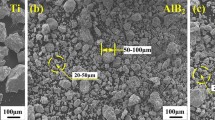

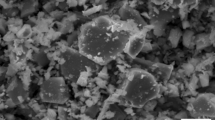

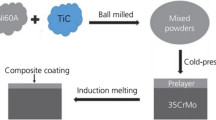

TiN-VC reinforced VN alloy/Co-based composite coatings were fabricated on mild steel by laser cladding. High temperature oxidation and tribological properties of the composite coatings were researched. Results illustrated that TiN and VC phases were in-situ synthesized in the composite coatings and appeared the aggregation phenomenon. Compared with VN alloy/Co-based composite coatings and substrate, the mass gain of the TiN-VC reinforced VN alloy/Co-based composite coatings after oxidation at 1000 °C was decreased by 16.98 and 89.74%, respectively. The oxidation kinetics curve complied with the parabolic law. The oxidation mechanism was that preferentially formed TiO2 oxidation film with pore structure promoted a few inward diffusional O atoms and outward diffusional Cr and Co atoms to form a thin continuous and dense Cr2O3 and CoO oxidation film, which reduced the oxidation rate of the composite coatings. The mass loss of the TiN-VC reinforced VN alloy/Co-based composite coatings at 600 °C was, respectively, decreased by 23.95 and 97.61%, and the friction coefficient was also obviously decreased. The worn mechanism was the comprehensive action of the abrasive wear, adhesive wear and oxidation wear.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

F.R. Long, S.I. Baik, D.W. Chung, F. Xue, E.A. Lass, D.N. Seidman and D.C. Dunand, Microstructure and Creep Performance of a Multicomponent Co-Based L12–Ordered Intermetallic Alloy, Acta Mater., 2020, 196, p 396–408.

T.L. Achmad, W. Fu, H. Chen, C. Zhang and Z.-G. Yang, Effect of Solute Segregation on the Intrinsic Stacking Fault Energy of Co-Based Binary Alloys: A First-Principles Study, J. Alloys Compd., 2018, 748, p 328–337.

T.L. Achmad, W. Fu, H. Chen, C. Zhang and Z.-G. Yang, Computational Thermodynamic and First-Principles Calculation of Stacking Fault Energy on Ternary Co-Based Alloys, Comp. Mater. Sci., 2018, 143, p 112–117.

J. Zhao, Q. Gao, H. Wang, F. Shu, H. Zhao, W. He and Yu. Zhishui, Microstructure and Mechanical Properties of Co-Based Alloy Coatings Fabricated by Laser Cladding and Plasma Arc Spray Welding, J. Alloys Compd., 2019, 785, p 846–854.

L. Li, L. Wei, Xu. Yanjin, L. Mao and Wu. Sujun, Study on the Optimizing Mechanisms of Superior Comprehensive Properties of a Hot Spray Formed Al-Zn-Mg-Cu Alloy, Mater. Sci. Eng. A, 2019, 742, p 102–108.

A.G. Mora-García, M. Mosbacher, J. Hastreiter, R. Völkl, U. Glatzel and J. Muñoz-Saldaña, Creep Behavior of Polycrystalline and Single Crystal Ni-Based Superalloys Coated with Ta-Containing NiCoCrAlY by High-Velocity Oxy-Fuel Spraying, Scripta Mater., 2020, 178, p 522–526.

S.W. Rukhande and W.S. Rathod, An Isothermal Oxidation Behaviour of Atmospheric Plasma and High-Velocity Oxy-Fuel Sprayed Nickel Based Coating, Ceram. Int., 2020, 46, p 18498–18506.

J.-B. Song, E. Choi, Oh. Seong-Geun, J. So, S.-S. Lee, J.-T. Kim and J.-Y. Yun, Improved Reliability of Breakdown Voltage Measurement of Yttrium Oxide Coatings by Plasma Spray, Ceram. Int., 2019, 45, p 22169–22174.

V. Carnicer, M.J. Orts, R. Moreno and E. Sánchez, Engineering Zirconia Coating Microstructures by Using Saccharides in Aqueous Suspension Plasma Spraying Feedstocks, Ceram. Int., 2020, 46, p 23749–23759.

C. Zhao, W. He, J. Shi, Q. Guo, J. Li and H. Guo, Deposition Mechanisms of Columnar Structured La2Ce2O7 Coatings Via Plasma Spray-PVD, Ceram. Int., 2020, 46, p 13424–13432.

B. Guo, J. Zhang, Wu. Mingtao, Q. Zhao, H. Liu, A. Monier and J. Wang, Water Assisted Pulsed Laser Machining of Micro-Structured Surface on CVD Diamond Coating Tools, J. Manuf. Process., 2020, 56, p 591–601.

K. Feng, Y. Chen, P. Deng, Y. Li, H. Zhao, Lu. Fenggui, R. Li, J. Huang and Z. Li, Improved High-Temperature Hardness and Wear Resistance of Inconel625 Coatings Fabricated by Laser Cladding, J. Mater. Proc. Technol., 2017, 243, p 82–91.

H.-H. Wang, H.-J. Li, X.-H. Shi, X.-S. Liu, J.-A. Kong and H. Zhou, Repair of SiC Coating on Carbon/Carbon Composites by Laser Cladding Technique, Ceram. Int., 2020, 46, p 19537–19544.

M. Erfanmanesh, R. Shoja-Razavi, H. Abdollah-Pour, H. Mohammadian-Semnani, M. Barekat and S. HamidHashemi, Friction and Wear Behavior of Laser Cladded WC-Co and Ni/WC-Co Deposits at High Temperature, Int. J. Refract. Met. Hard Mater., 2019, 81, p 137–148.

]D. Bartkowski, A.M. łynarczak, A. Piasecki, B.ł. Dudziak, M. Goś ciań ski, A. Bartkowska, Microstructure, Microhardness and Corrosion Resistance of Stellite-6 Coatings Reinforced with WC Particles Using Laser Cladding, Opt. Laser Technol., 2015, 68(191), p 201.

J. Liang, Y. Liu, J. Li, Y. Zhou and X. Sun, Epitaxial Growth and Oxidation Behavior of an Overlay Coating on a Ni-Base Single-Crystal Superalloy by Laser Cladding, J. Mater. Sci. Technol., 2019, 35, p 344–350.

H. Yan, Z. Chen, J. Zhao, P. Zhang, Z. Yu and Q. Lu, Enhancing Tribological Properties of WS2/NbC/Co-Based Self-Lubricating Coating Via Laser Texturing and Laser Cladding Two-Step Process, J. Mater. Res. Technol., 2020, 9, p 9907–9919.

J. Zhang, J. Lei, Gu. Zhenjie, F. Tantai, H. Tian, J. Han and Y. Fang, Effect of WC-12Co Content on Wear and Electrochemical Corrosion Properties of Ni-Cu/WC-12Co Composite Coatings Deposited by Laser Cladding, Surf. Coat. Technol., 2020, 393, p 1–9.

G. Wang, J. Zhang, R. Shu and S. Yang, High Temperature Wear Resistance and Thermal Fatigue Behavior of Stellite-6/WC Coatings Produced by Laser Cladding with Co-Coated WC Powder, J. Mater. Res. Technol., 2019, 81, p 63–70.

F. Weng, Yu. Huijun, C. Chen, J. Liu, L. Zhao and J. Dai, Microstructure and Property of Composite Coatings on Titanium Alloy Deposited by Laser Cladding with Co42+TiN Mixed Powders, J. Alloys Compd., 2016, 686, p 74–81.

L. Ding, Hu. Shengsun, X. Quan and J. Shen, Effect of VN Alloy Addition on the Microstructure and Wear Resistance of Co-Based Alloy Coatings, J. Alloys Compd., 2016, 659, p 8–14.

I. Hulka, D. Utu, V.A. Serban, P. Negrea, F. Luká č and T. Chráska, Effect of Ti Addition on Microstructure and Corrosion Properties of Laser Cladded WC-Co/NiCrBSi(Ti) Coatings, Appl. Surf. Sci., 2020, 504(144349), p 1–15.

M. Zhang, S.S. Liu, Y.Y.S.X. Luo and K.L. Qu, Effect of Molybdenum on the High Temperature Properties of TiC-TiB2 Reinforced Fe-based Composite Laser Cladding Coatings, J. Alloys Comp., 2018, 742, p 383–390.

Ma. Qunshuang, C. Haozhe, Z. Hui, Hu. Meng Wei, L.H. Lei, Wu. Yitao and Y. Xiaohui, The Alloying Effects of Cr on In-Situ Phase Evolution and Wear Resistance of Nickel Composite Coatings Fabricated by Wide-Band Laser Deposition, Surf. Coat. Technol., 2020, 397(126019), p 1–11.

L. Ding, Hu. Shengsun, X. Quan and J. Shen, Effect of Ti on the Microstructure Evolution and Wear Behavior of VNalloy/Co-Based Composite Coatings by Laser Cladding, J. Mater. Proc. Technol., 2018, 252, p 711–719.

D. Yang and Z. Shen, Corrosion science of metal, Metallurgical industry press, Beijing, 1999.

Y. Hirohata, D. Motojima, T. Hino and S. Sengoku, Suppression of Hydrogen Absorption to V-4Cr-4Ti Alloy by TiO2/TiC Coating, J. Nucl. Mater., 2003, 313–316, p 172–176.

K. Dohdai, C. Boher, F. Rezai-aria and N. Mahayotsanun, Tribology in Metal Forming at Elevated Temperatures, Friction, 2015, 3(1), p 1–27.

A. Skopp and M. Woydt, Unlubricated Sliding Friction and Wear of Various Si3N4 Pairs Between 22–1000 °C, Tribol. Int., 1990, 12, p 153–158.

Acknowledgments

This author wish to express thanks for financial support of Excellent Young Talents Fund Program of Higher Education Institutions of Anhui Province of China (no. gxyq2019073) and High Level Talents Fund Program of West Anhui University (no. 12).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ding, L., Hu, S., Wang, H. et al. Oxidation Behavior and High Temperature Friction and Wear Resistance of TiN-VC Reinforced VN Alloy/Co-Based Composite Coatings by Laser Cladding. J. of Materi Eng and Perform 31, 3481–3492 (2022). https://doi.org/10.1007/s11665-021-06497-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06497-3