Abstract

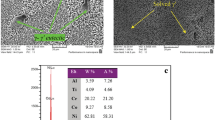

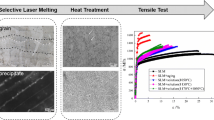

In this study, to investigate the impact of heating rate, the IN738LC superalloy was solutionized both in standard and salt bath conditions. For this purpose, the samples were solutionized in the temperature range of 1090–1200 °C for 30–120 minutes in normal conditions and 10–120 minutes in the salt bath. Afterward, samples were aged at 850 °C for 24 hours. The results of scanning electron microscopy (SEM) and field emission scanning electron microscopy (FESEM) showed that as the heating rate increased, the dissolution process improved. In contrast, as the time and temperature increased, the γ' precipitates’ volume fraction decreased in both the normal condition and the salt bath by 26.01 and 50.28 %, respectively. The size of the remaining γ' precipitates after dissolution in the salt bath was about 16 nm smaller than normal ones. The size and volume fraction of the residual precipitates in the salt bath increased at high temperatures compared to the normal ones due to the attachment mechanisms’ activation. Solubility in the salt bath reduced the size of primary γ' in the normal range and increased the volume fraction of the secondary γ' precipitates after the aging. This alloy’s hardness is strongly influenced by the characteristics of the γ precipitates and the solutionizing process variables. Therefore, the results indicated that the secondary γ' precipitates are about 16 nm smaller than the usual one, which has a remarkable impact. After aging, increasing the heating rate during the solutionizing resulted in a further rise in the hardness and reduced the hardness after solutionizing. However, in both conditions, as the time of solutionizing reduced and temperature increased, the samples’ hardness after solution decreased, and the hardness after aging increased.

Similar content being viewed by others

Notes

Lifshitz, Slyozov and Wagner

References

C.R. Reed, The Superalloys Fundamentals and Applications, Cambridge University Press, London, 2006.

M.B. Boyce, An Overview of Gas Turbines, Gas Turbine Engineering Handbook, Fourth Ed., Elsevier BV, (2012)

N. Kontikame, S. Polsilapa and P. Wangyao, Effect of Precipitation Aging Temperatures on Reheat Treated Microstructures and its Phase Stability after Long-Term Exposure in Cast Nickel Base Superalloy, Grade Inconel 738, Mater. Sci., 2017, 891, p 433–437. (in English)

P. Strunz, M. Petrenec, U. Gasser, J. Tobias, J. Polak and J. Saroun, Precipitate Microstructure Evolution in Exposed IN738LC Superalloy, J. Alloys. Compd., 2014, 589, p 462–471. (in English)

Shajari. Y., Razavi. S.H., Microstructural Investigation of Volume Fraction and size of nano γ' in A Ni-Base Superalloy after Solution. In 5th International Conference of Materials Engineering and Metallurgy, Shiraz, Iran, 2016, in Persian

E. Lvova, A Comparison of Aging Kinetics of New and Rejuvenated Conventionally Cast GTD-111 Gas Turbine Blades, J. Mater. Eng. Perform., 2007, 16, p 254–264. (in English)

J. Brenneman, J. Wei, Z. Sun, L. Liu, G. Zou and Y. Zhou, Oxidation Behavior of GTD111 Ni-Based Superalloy at 900 °C in Air, Corros. Sci., 2015, 100, p 267–274. (in English)

B. Galizoni, A.A. Couto and D. Reis, Heat Treatments Effects on NickeI-Based Superalloy Inconel 713C, Defect. Diffusion. Forum., 2019, 9, p 32–40. (in English)

C. Monti, A. Giorgetti, L. Tognarelli and F. Mastromatteo, On the Effects of the Rejuvenation Treatment on Mechanical and Microstructural Properties of IN-738 Superalloy J, Mater. Eng. Perform., 2017, 26, p 2244–2256. (in English)

S.A. Sajadi, H.R. Elahifar and H. Farhangi, Effects of Cooling Rate on the Microstructure and Mechanical Properties of the Ni-Base Superalloy UDIMET 500, J. Alloys. Compd., 2008, 455, p 215–220. (in English)

A.K. Ray, S.R. Singh, J. Swaminathan, P.K. Roy, Y.N. Tiwari, S.C. Bose and R.N. Ghosh, Structure Property Correlation Study of a Service Exposed First Stage Turbine Blade in a Power Plant, Mater. Sci. Eng. A., 2006, 419, p 225–232. (in English)

S.H. Razavi, S.H. Mirdamadi, J. Szpunar and H. Arabi, Imprvement of Age Hardening Process of a Nickel-Base Superalloy, IN-738LC, Mater. Sci., 2002, 37, p 1461–1471. (in English)

S.H. Razavi, S. Mirdamadi, H. Arabi and J. Szpunar, Mathematical Model of Influence of Rapid induction Heating on Nucleation and Growth of Precipitates, Mater. Sci. Technol., 2001, 17, p 1205–1210. (in English)

E415-14, Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry, ASTM, (2014)

E92-16., Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials, ASTM, Feb (2016)

A. Khodabakhshi, A. Mashreghi, Y. Shajari and S.H. Razavi, Investigation of Microstructure Properties and Quantitative Metallography by Different Etchants in the Service-Exposed Nickel-Based Superalloy Turbine Blade, Trans. Indian Inst. Met., 2018, 71, p 849–859. (in English)

R. Salehi, A. Samadi and MKh. Savadkohi, Influence of Etchants on Quantitative/Qualitative Evaluations of the γ′ Precipitates in a Nickel-Base Superalloy, Metallogr. Microstruct. Anal., 2012, 1, p 290–296. (in English)

R.J. Mitchell, M. Preuss, S. Tin and M.C. Hardy, The Influence of Cooling Rate from Temperatures Above the γ′ Solvus on Morphology, Mismatch and Hardness in Advanced Polycrystalline Nickel-Base Superalloys, Mater. Science. Eng. A., 2008, 473, p 158–165. (in English)

E. Balikci, A. Raman and R.A. Mirshams, Influence of Various Heat Treatments on the Microstructure of Polycrystalline IN738LC, Metall. Mater. Trans. A., 1997, 28, p 1993–2003. (in English)

B. Ruttert, D. Burger, L.M. Roncery and P.A.B. Arsa, Rejuvenation of Creep Resistance of a Ni-Base Single-Crystal Superalloy by Hot Isostatic Pressing, Mater. Des., 2017, 134, p 418–425. (in English)

H. Yang, J. Zhang and Z. Zhang, Rejuvenation Heat Treatment’s Influence on the Microstructure and Properties of Superalloys, Mater. Sci. Tech., 2018, 18, p 1018–1024. (in English)

S.H. Razavi, S.H. Mirdamadi, H. Arabi, J. Szpunar, An Improved Method for Age Hardening of a Superalloy , US. Provisional patent, (2001), 60/309, 610, in English

J. Tiley, G.B. Viswanathan, R. Srinivasan and R. Banerjee, Coarsening Kinetics of γ′ Precipitates in the Commercial Nickel Base Superalloy René 88 DT, Acta Mater., 2009, 57, p 2538–2549. (in English)

R.S. Moshatghin and S. Asgari, The Effect of Thermal Exposure on the γ′ Characteristics in a Ni-Base Superalloy, J. Alloys. Compd., 2004, 368, p 144–151. (in English)

J. Anderson, G.P. Sjoberg, L. Viskari and M. Cheturvedi, Effect of Solution Heat Treatments on Superalloys Part 1 – Alloy 718, Mater. Sci. Technol., 2012, 28, p 609–619. (in English)

P. Shewmon., Diffusion in Solids, 2nd Ed., Wiley, (2012)

M.P. Jackson, M.J. Starink and R.C. Reed, Determination of the Precipitation Kinetics of Ni3Al in the Ni–Al System Using Differential Scanning Calorimetry, Mater. Sci. Eng., 1999, 264, p 26–38. (in English)

H. Monajati, M. Jahazi, R. Bahrami and S. Yuec, The Influence of Heat Treatment Conditions on γ′ Characteristics in Udimet 720, Mater. Sci. Eng. A., 2004, 373, p 286–293. (in English)

A. Baldan, Rejuvenation Procedures to Recover Creep Properties of Nickel-Base Superalloys by Heat Treatment and Hot Isostatic Pressing Techniques, J. Mater. Sci., 1991, 26, p 3409–3421. (in English)

A. Yang, Y. Xiong and L. Liu, Effect of Cooling Rate on the Morphology of γ′ Precipitates in a Nickel–Base Superalloy Under Directional Solidification, Sci. Technol. Adv. Mater., 2011, 2, p 105–107. (in English)

C. Yang, H. Nie, Y. Xu and Z. Shen, Effects of Heat Treatments on the Microstructure and Mechanical Properties of Rene 80, Mater. Des., 2013, 43, p 66–73. (in English)

Z. Liao, D. Axinte, M. Mieszala, R. M’Saoubi, J. Michler and M. Hardyd, On the Influence of Gamma Prime Upon Machining of Advanced Nickel Based Superalloy, CIRP Ann., 2018, 67, p 109–112. (in English)

N. El-Bagoury, M. Waly and A. Nofal, Effect of Various Heat Treatment Conditions on Microstructure of Cast Polycrystalline IN738LC alloy, Mater. Sci. Eng. A., 2008, 487, p 152–216. (in English)

R.E. Smallman., A.H.W. Ngan., Physical Metallurgy and Advanced Material, Butterworth-Heinemann, (2011)

Y.Q. Chen, T.J.A. Slater, E.A. Lewis, E.M. Francis, M.G. Burke, M. Preuss and S.J. Haigh, Measurement of Size-Dependent Composition Variations for Gamma Prime (γ′) Precipitates in an Advanced Nickel-Based Superalloy, Ultramicroscopy, 2014, 144, p 1–8. (in English)

J.R. May, M.C. Hardy, M.R. Bache and D.D. Kaylor, Microstructure and Mechanical Properties of an Advanced Nickel-Based Superalloy in the as-HIP Form, Adv. Mat. Res., 2011, 278, p 265–270. (in English)

J. Safari and S. Nategh, On the Heat Treatment of Rene-80 Nickel-Base Superalloy, J. Mater. Process. Tech., 2006, 176, p 240–250. (in English)

Z. Mazur, A.L. Ramirez, J.A. Islas and C. Amezcua, Failure Analysis of a Gas Turbine Blade Made of INCONEL 738LC Alloy, Eng. Fail. Anal., 2005, 12, p 474–486. (in English)

D.A. Porter., Phase Transformation in Metals and Alloy, Chapman & Hall, (1992)

Z. Xinbou, D. Yingying, Y. Hongfei, L. Jinato, Y. Yang, Y. Zhen, Y. Jingho and G. Yuefeng, Effect of Heat Treatment on the Microstructure of a Ni–Fe Based Superalloy for Advanced Ultra-Supercritical Power Plant Applications, Prog. Nat. Sci., 2016, 16, p 204–209. (in English)

Y. Shajari, Z.S. Seyedraoufi, A. Alizadeh, S.H. Razavi, M. Porhonar and K. Mirzavand, Effect of Solution Temperature of rejuvenation Heat Treatment on the Stability of γ’ Precipitates in Ni-Base Superalloy IN738LC During Long-Term Heating, Mater. Res. Express., 2019, 6, p 126571. (in English)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shajari, Y., Razavi, S.H. & Seyedraoufi, ZS. Comparative Study of Solution Heat Treatment of IN738LC Superalloy in Conventional Conditions and Salt Bath. J. of Materi Eng and Perform 31, 2525–2541 (2022). https://doi.org/10.1007/s11665-021-06344-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06344-5